An intensive smoke plume treatment and purification system and method

A purification system and intensive technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of ineffective plume treatment, poor treatment effect, difficult implementation of plume treatment, etc., and achieve energy recycling. , Small temperature fluctuation, reducing the effect of additional equipment in the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

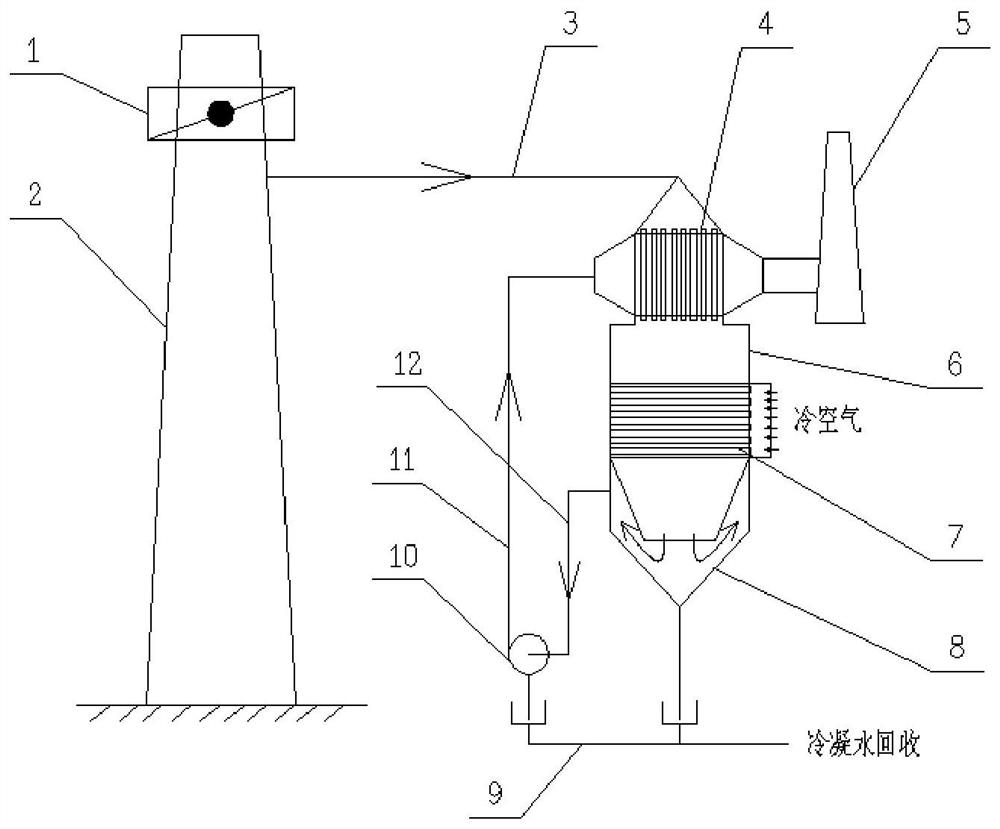

[0044] Such as figure 1As shown, an intensive high-efficiency plume treatment and purification system of the present invention includes a first heat exchanger 4, a middle header 6, a second heat exchanger 7, a gas collector and dehydrator 8, a condensed water recovery mechanism 9, a first The fan and the second fan 10, the first heat exchanger 4 communicates with the second heat exchanger 7 through the middle header 6, the second heat exchanger 7 communicates with the gas collector and dehydrator 8, and the pipe side inlet of the second heat exchanger 7 communicates with The first fan obtains cold air, and the flue gas in the second heat exchanger 7 can exchange heat with the cold air, and the condensed water recovery mechanism 9 is installed at the bottom of the gas collector and dehydrator 8 and the fan; the outlet on the shell side of the second heat exchanger 7 communicates The inlet of the second fan 10, the outlet of the second fan 10 is connected to the shell-side inlet...

Embodiment 2

[0061] Embodiment 2 discloses an intensive smoke plume treatment and purification method, the flue gas flows through the tube body of the first heat exchanger 4 and the shell of the second heat exchanger 7, and the original flue gas passes through the first heat exchanger 4 After the preliminary cooling, the temperature is further lowered in the second heat exchanger 7 .

[0062] The flue gas cooled by the first heat exchanger 4 and the second heat exchanger 7 is discharged through the tail gas discharge chimney 5 after heat exchange with the high-temperature raw flue gas in the first heat exchanger 4 .

[0063] Specifically, the intensive smoke plume treatment and purification method specifically includes the following steps:

[0064] 1) The flue gas passes through the pipe fittings of the first heat exchanger 4, and the exhaust gas passes through the shell of the first heat exchanger 4, so as to ensure that the temperature inside the pipe fittings is maintained at a relative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com