Supply mechanism of container inner wall cleaning device for machining

一种机械加工、内壁清洗的技术,应用在烘干机、清洁空心物品、干燥气体布置等方向,能够解决水资源浪费、冲洗烘干时间长、效率低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0028] The following is a specific embodiment of the device for cleaning the inner wall of a container for machining.

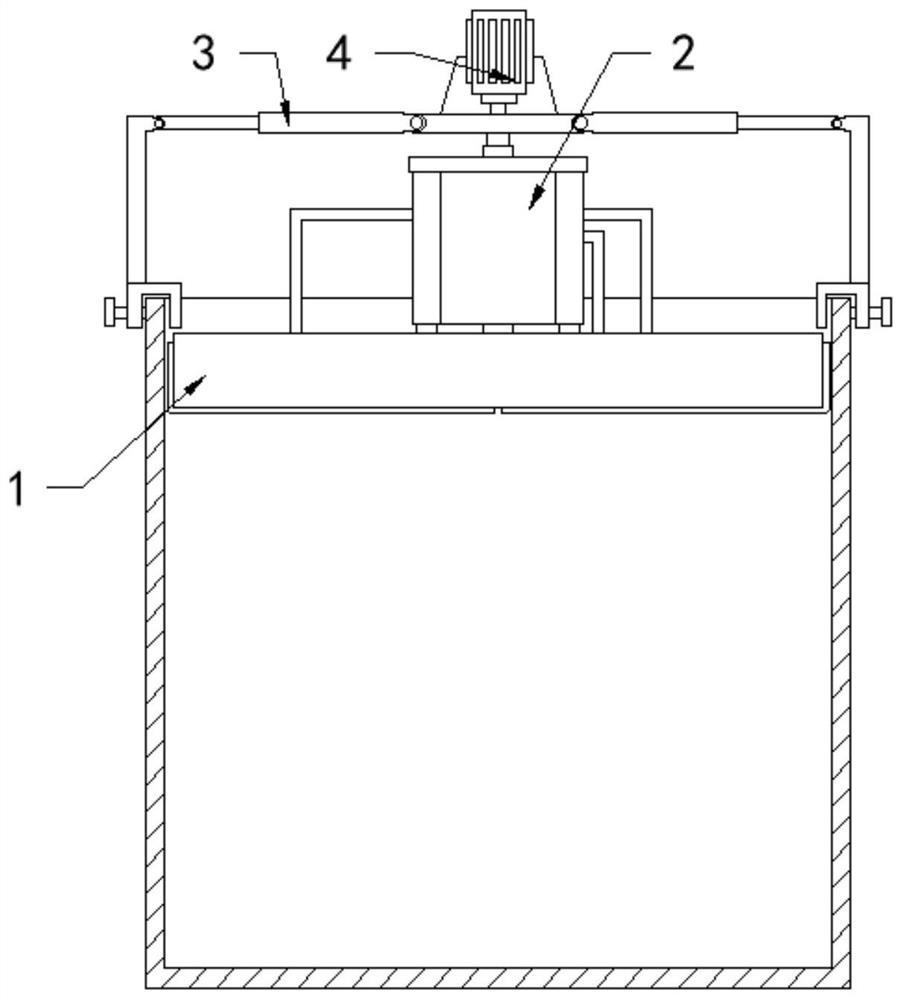

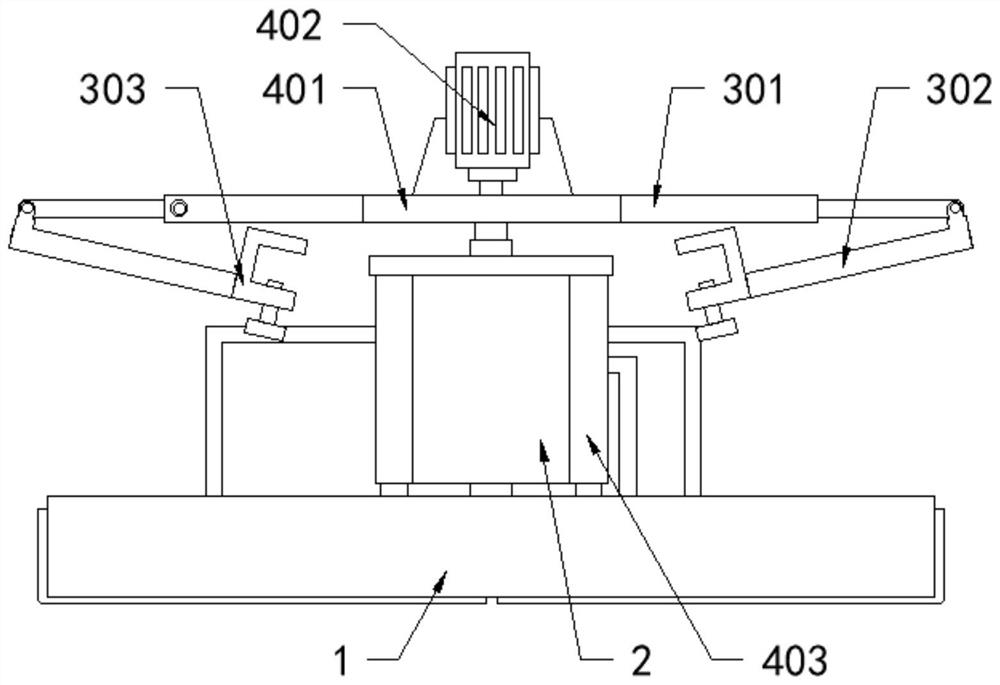

[0029] refer to Figure 1-6 , a device for cleaning the inner wall of a container for mechanical processing, including a cleaning mechanism 1, a supply mechanism 2, a driving mechanism 4 and a support assembly 3;

[0030] The cleaning mechanism 1 includes an axis column 102, a first concentration box 104 and a second concentration box 1011 are symmetrically arranged on both sides of the axis column 102, and a heating plate covered with a wiping cloth 108 is installed on the outside of the first concentration box 104 107, the outside of the second concentration box 1011 is respectively connected with a recovery port 1012 and a drying port 1013;

[0031] The supply mechanism 2 includes a first storage tank 202 and a second storage tank 203 for providing liquid to the first concentration tank 104, and the supply mechanism 2 also includes a hot air blower 207 fo...

specific Embodiment approach 2

[0036] The following is a specific embodiment of the device for cleaning the inner wall of a container for machining.

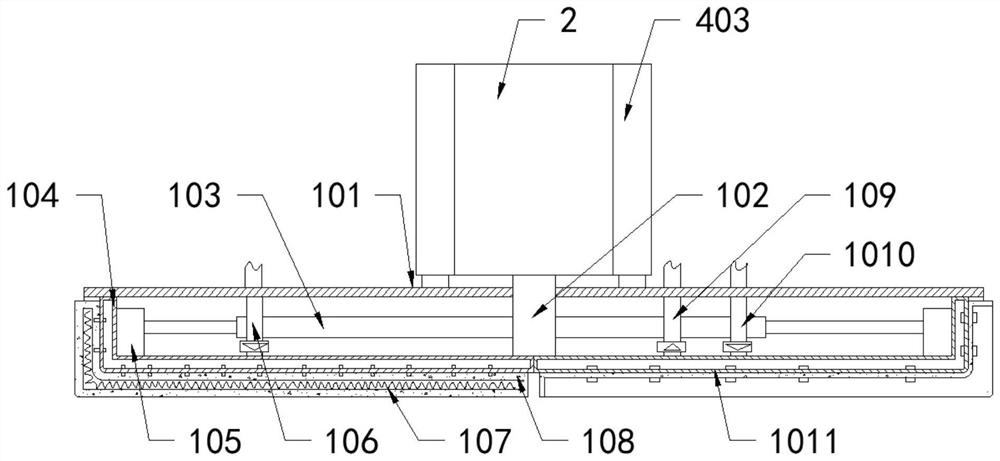

[0037] The cleaning device for the inner wall of the container for mechanical processing in this embodiment is further defined on the basis of the first embodiment, the cleaning mechanism 1 further includes a top shell 101 installed with the axis column 102, and the two sides of the axis column 102 are installed symmetrically. There are stretching cylinders 103, and the extension ends of the two sets of stretching cylinders 103 are fixedly connected with abutment plates 105, and the two sets of abutment plates 105 are respectively connected with the first concentration box 104 of L-shaped structure and the second concentration box 1011 of L-shaped structure. fixed connection, such as image 3 shown;

[0038] In this embodiment, by driving the stretching cylinder 103, the first concentration box 104 and the second concentration box 1011 made of silica gel are...

specific Embodiment approach 3

[0040] The following is a specific embodiment of the device for cleaning the inner wall of a container for machining.

[0041] The cleaning device for the inner wall of the container for mechanical processing in this embodiment, on the basis of the first embodiment, further defines that the supply mechanism 2 also includes a storage box 201, and the first storage tank 202 and the second storage tank 203 are installed in the storage tank. In the box 201, a first water pump 204 is also installed in the storage box 201, the input end of the first water pump 204 communicates with the first material storage tank 202 and the second material storage tank 203 respectively through a solenoid valve, and the output end of the first water pump 204 The transfusion tube 106 that is equipped with solenoid valve is communicated with the first collection box 104, and the first collection box 104 is communicated with wiping cloth 108 by penetration hole, as Figure 1-5 shown;

[0042] In this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com