Doublestage desulfurizing and dedusting apparatus

A technology for desulfurization, dust removal, and dust removal devices, which is used in the separation of dispersed particles, chemical instruments and methods, and the use of liquid separators. problems, to achieve the effect of compact equipment, space saving and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

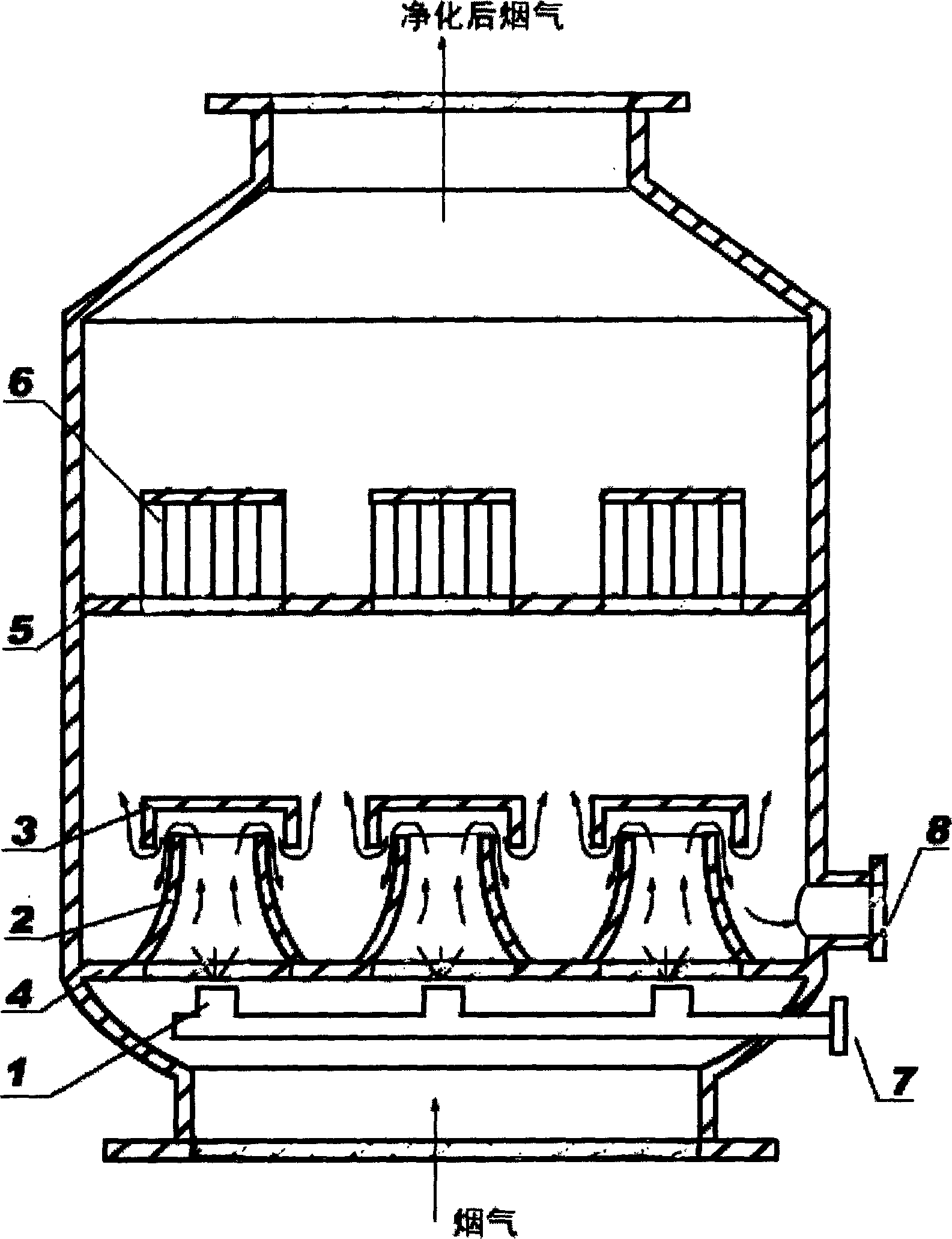

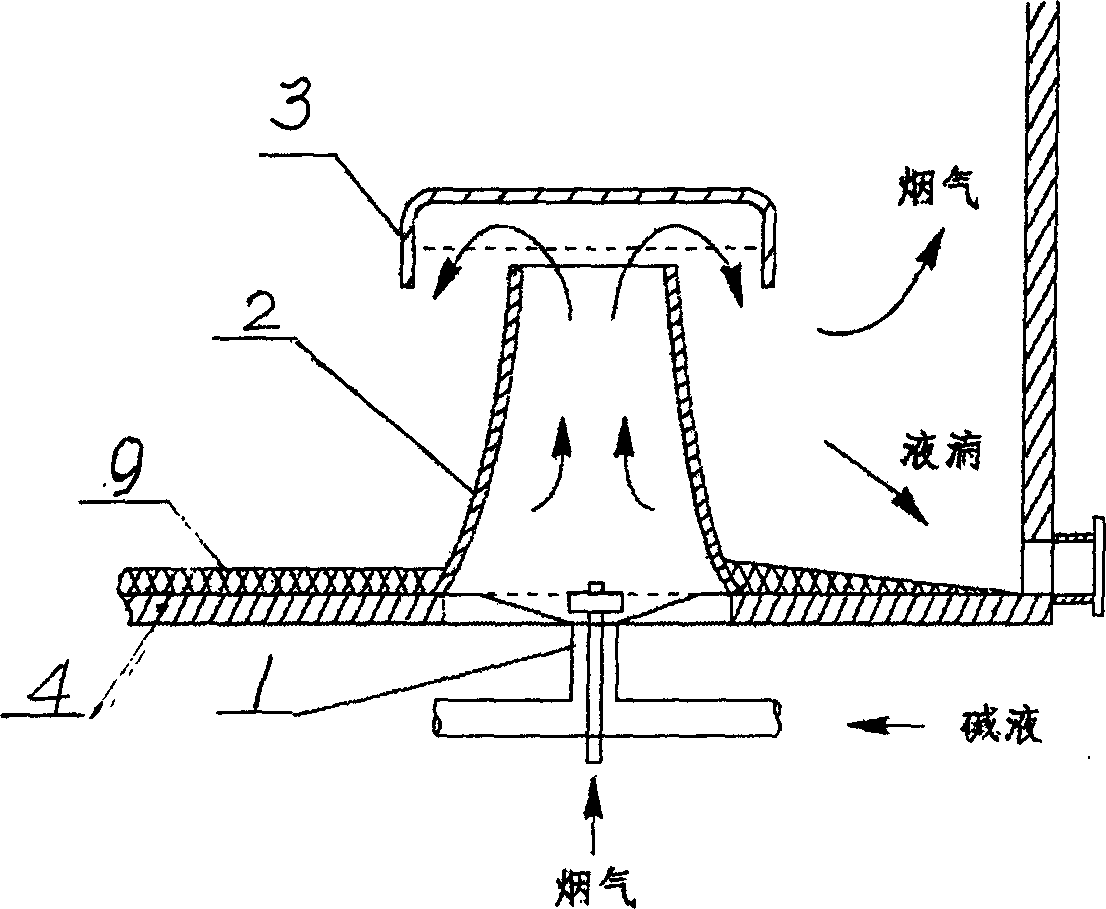

[0011] The secondary desulfurization and dust removal device of the present invention includes a casing and an alkali liquor circulation system. Its shell is a tank with an open top and bottom.

[0012] A supporting partition 4 is fixed on the lower part of the tank body, and a plurality of circular holes are arranged on the plate, and each hole is correspondingly fixed with a low-velocity Venturi tube 2 with a flow rate of 15-20 meters per second. On the top of the inner pipe, a deflector strikes the baffle plate 3 is fixed. The corresponding low-velocity Venturi tube position below the supporting partition is provided with a shower nozzle 1 communicated with the lye pipe, and this shower nozzle is a low-resistance nozzle that requires its resistance to drop within 2 meters of water column. The surface of the supporting partition is also coated with a coating 9 made of water glass and cast stone powder.

[0013] A mounting plate 5 is also fixed on the upper part of the tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com