Color paste for water-based paints and production technique thereof

A water-based coating and production process technology, applied in anti-corrosion coatings, pigment pastes, etc., can solve the problems of high energy consumption and reduce production efficiency, and achieve the effects of avoiding external force damage, reducing energy consumption, and shortening cooling time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

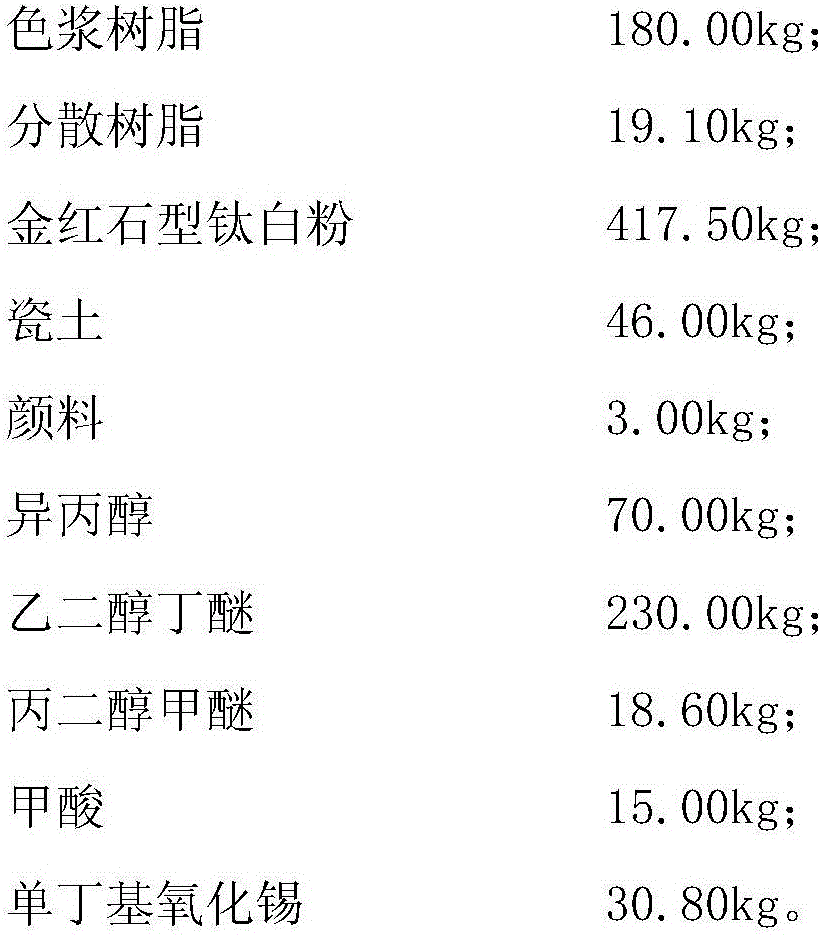

[0028] A kind of color paste for water-based paint, is made up of following raw material:

[0029]

[0030] As a catalyst, monobutyl tin oxide can effectively catalyze the crosslinking time and leveling time of the resin, and can also quickly dehydrate the paint film, reduce the curing temperature and shorten the curing time of the paint film, improve production efficiency, and reduce production capacity. consumption.

[0031] The production technology of above-mentioned water-based paint color paste, comprises the following steps:

[0032] Step 1: Check whether the sand mill is clean and whether the valves are in place;

[0033] Step 2: Add all raw materials except formic acid into the grinding tank of the sand mill in turn, stir with a high-speed mixer at 2100 rpm for 0.8 hours, grind the materials finely and stir until the materials heat up, and then let stand for 2 hours After the material is fully reacted, add grinding beads, grind the material to a fineness of 13 μm...

Embodiment 2

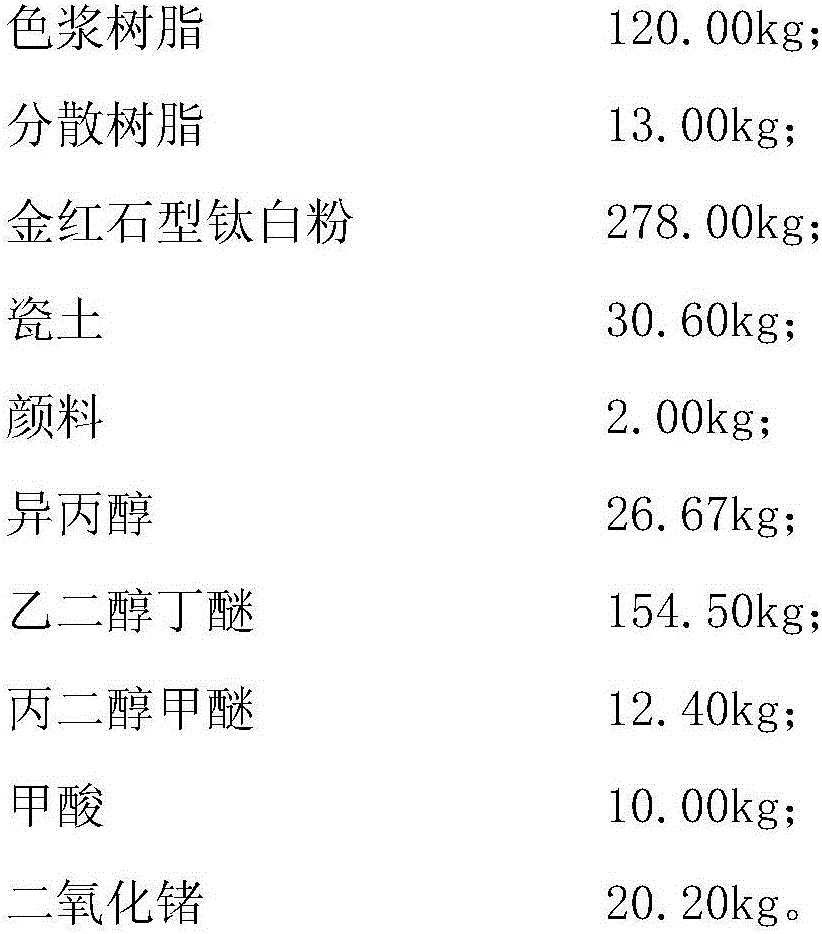

[0037] A kind of color paste for water-based paint, is made up of following raw material:

[0038]

[0039] Germanium dioxide is an esterification catalyst, which can effectively catalyze the crosslinking time and leveling time of the resin, and can also quickly dehydrate the paint film, reduce the curing temperature and shorten the curing time of the paint film, improve production efficiency, and reduce production capacity. consumption.

[0040] The production technology of above-mentioned water-based paint color paste, comprises the following steps:

[0041] Step 1: Check whether the sand mill is clean and whether the valves are in place;

[0042] Step 2: Add all raw materials except formic acid into the grinding tank of the sand mill in turn, stir with a high-speed mixer at 2200 rpm for 0.6 hours, grind the materials finely and stir until the materials are heated, and then stand for 2.5 hours to wait The material is fully reacted, then add grinding beads, grind the mat...

Embodiment 3

[0045] A kind of color paste for water-based paint, is made up of following raw material:

[0046]

[0047]

[0048] As a catalyst, tetrabutyltin can effectively catalyze the crosslinking time and leveling time of the resin, and can also quickly dehydrate the paint film, reduce the curing temperature and shorten the curing time of the paint film, improve production efficiency, and reduce production energy consumption.

[0049] The production technology of above-mentioned water-based paint color paste, comprises the following steps:

[0050] Step 1: Check whether the sand mill is clean and whether the valves are in place;

[0051] Step 2: Add all raw materials except formic acid into the grinding tank of the sand mill in turn, stir with a high-speed mixer at 2000 rpm for 1 hour, grind the materials finely and stir until the materials heat up, and then let stand for 2 hours to wait The material is fully reacted, then add grinding beads, grind the material to a fineness of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com