Patents

Literature

87 results about "Phosphate minerals" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phosphate minerals contain the tetrahedrally coordinated phosphate (PO₄³⁻) anion along sometimes with arsenate (AsO₄³⁻) and vanadate (VO₄³⁻) substitutions. Chlorine (Cl⁻), fluorine (F⁻), and hydroxide (OH⁻) anions that also fit into the crystal structure.

Solid-chemical compositions, geochemical binder system, and improved high-shear granulation process for both conventional and slow-release fertilizer and bioremediation nutrient compositions

InactiveUS20020178772A1Less-expensive to produceWiden meansSolid/semi-solid fertilisersMatrix fertilisersSolubilityAdditive ingredient

This invention discloses advanced means for the formulation and preparation of solid-chemical compositions which provide sources of water-soluble nutrients, electron acceptors and other agents for agriculture and waste-treatment, in particular, the bioremediation of contaminated environmental media. The disclosed formulations and means of production of the slow-release solid-chemical compositions of the present invention utilize a novel and economical "biphasic" chemical-system technology which involves a combination of a first "nutrient" component (1) which comprises water-soluble nutrients and other biologically utilizable substances with a second component (2) which comprises an inorganic geochemical-binder system. The simplest embodiment of the geochemical-binder system comprises one or more salts of phosphoric acid. In the preferred embodiments of the present invention intended for the slow-release of the ingredients contained in the "nutrient" component (1), the geochemical-binder system of component (2) comprises a combination of one or more salts of phosphoric acid with a inorganic binder matrix preferably containing a mixture of low-solubility carbonates, carbonate minerals, phosphates and phosphate minerals. The different embodiments of the geochemical-binder system of this invention allows a wide variation of formulations of the nutrient component (1) to be prepared in both conventional and slow-release forms using an improved high-shear granulation process whereby the dangerous chemicals typically used in the granulation process are largely or completely replaced with water. The present invention discloses means by which such compositions can be economically prepared in large quantities so as to meet the specific needs of different sectors of the agricultural / agribusiness and phytoremediation / bioremediation markets. The disclosed solid-chemical compositions of the present invention provide improved, cost-effective means for slowing and controlling the release-rate profiles of water-soluble nutrients, such as nitrogen- and phosphorus-rich compounds, and improved means for enhanced and / or time-targeted nutrient uptake by plants and microorganisms. The present invention also provides improved means for the reduction of nutrient run-off from agricultural areas into surface waters and means of preventing or minimizing nutrient-contamination of ground-water aquifers.

Owner:HINCE ERIC CHRISTIAN MR

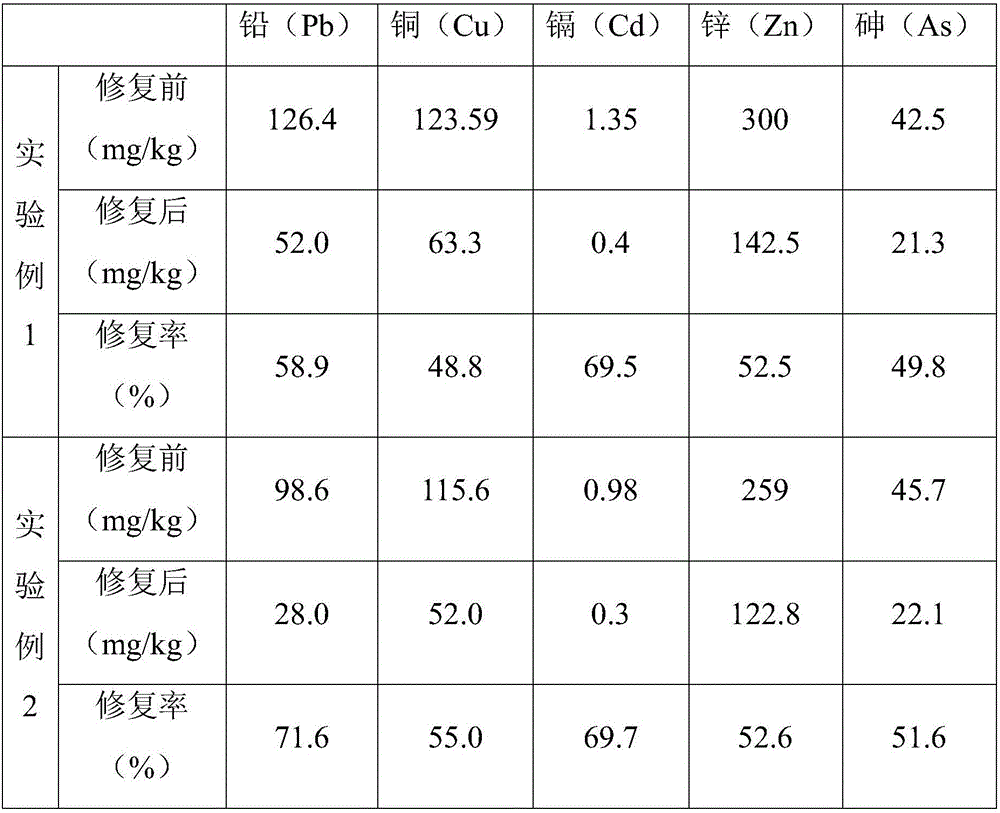

Composite heavy metal polluted soil in-situ fixing method

ActiveCN102303041APromote mineralization reactionQuick fixContaminated soil reclamationWater insolubleMagnesium sulfite

The invention discloses a composite heavy metal polluted soil in-situ fixing method. The method comprises the following steps of: preparing a heavy metal polluted soil restoration agent by using 80 to 90 weight parts of bentonite or kaolin serving as a filling agent, 0.5 to 15 weight parts of ferrous sulfide, 0.5 to 5 weight parts of magnesium sulfate, 1.5 to 8 weight parts of magnesium sulfite, 1 to 5 weight parts of magnesium oxide, 2 to 10 weight parts of calcium hydroxide and 1 to 5 weight parts of phosphorus-containing preparation; and mixing the components and heavy metal polluted soil according to the weight ratio of 1:(5-20), and uniformly stirring to make the humidity of the soil kept between 15 and 30 percent, wherein heavy metal ions in the polluted soil are converted into water-insoluble metal sulfides, hydroxides, multi-metal co-precipitates, basic carbonates and phosphate minerals, the biological activity of heavy metal is lost, and the heavy metal is fixed in the soil. The restored soil meets the requirement of second-level standard values of 'Environmental Quality Standard for Soil' (GB 15618-1995) in China.

Owner:刘阳生

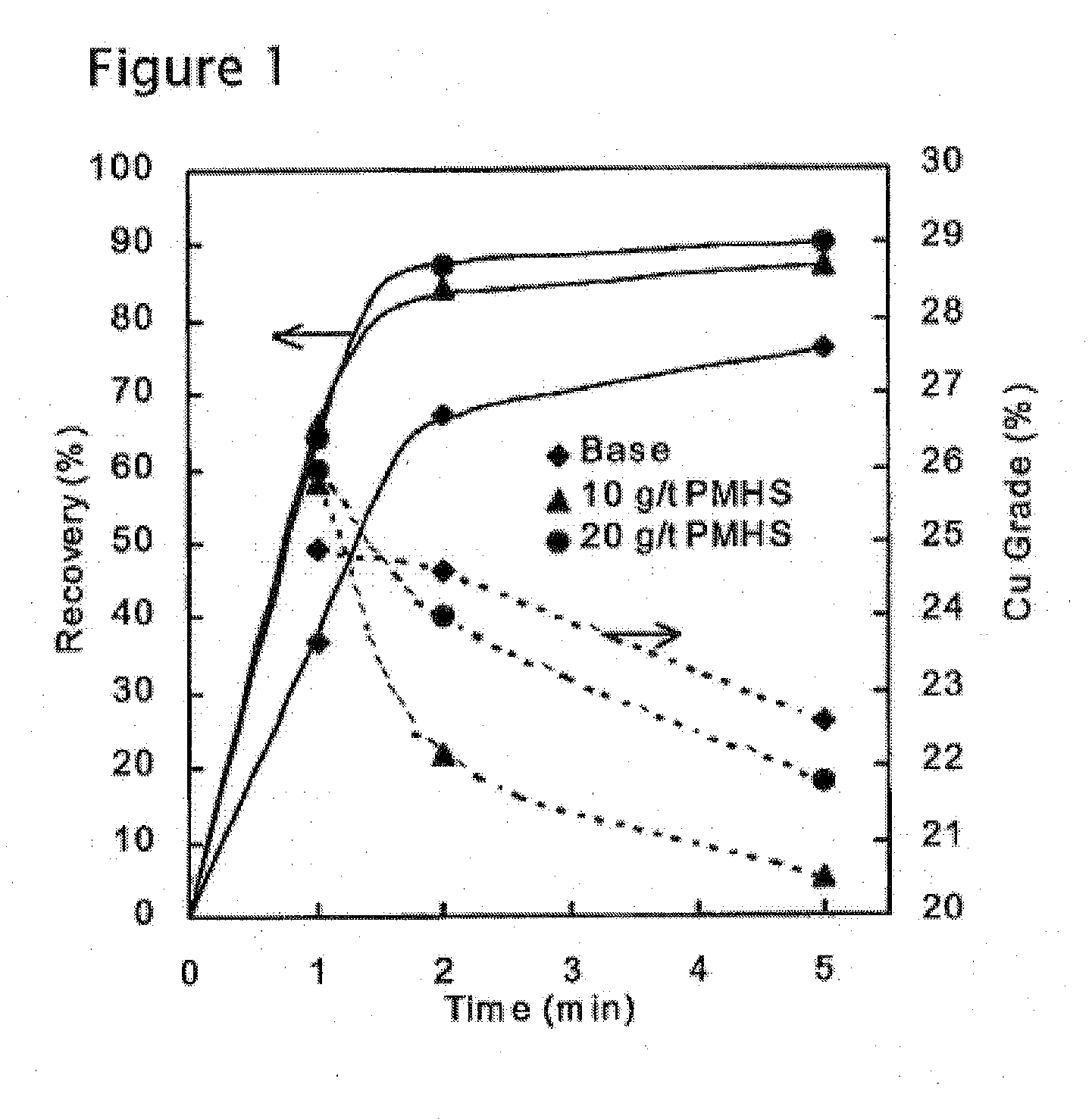

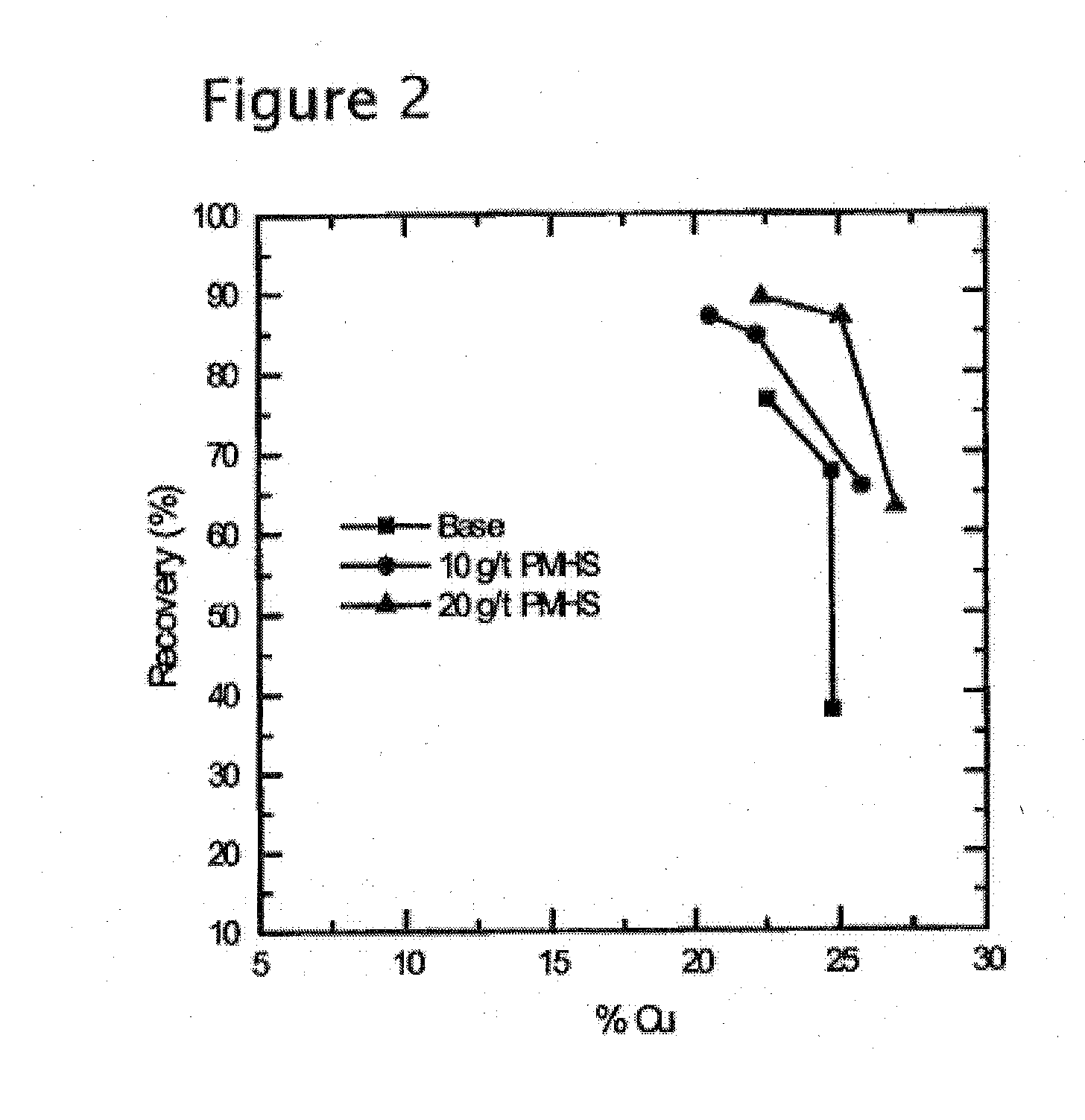

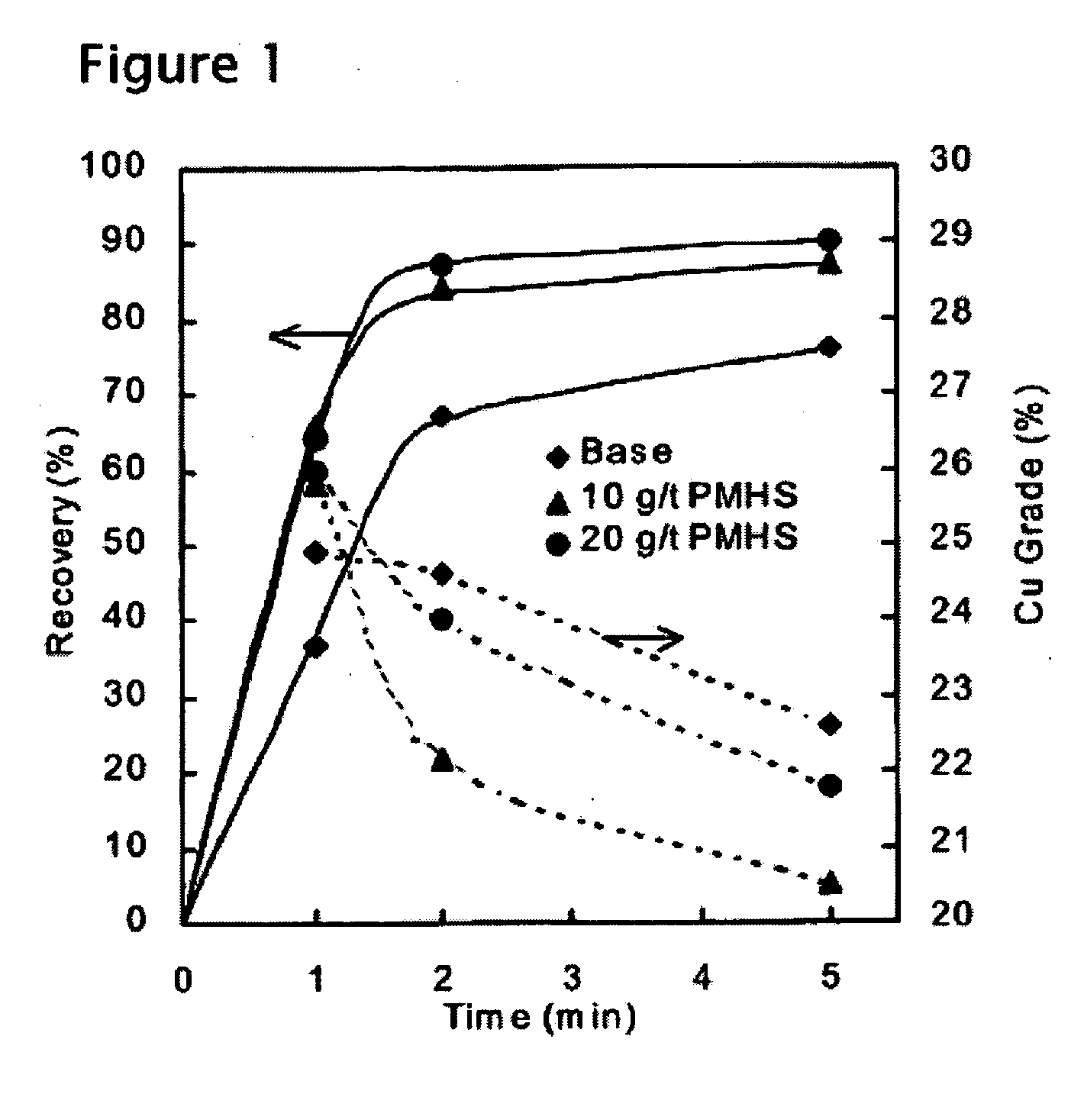

Methods of increasing flotation rate

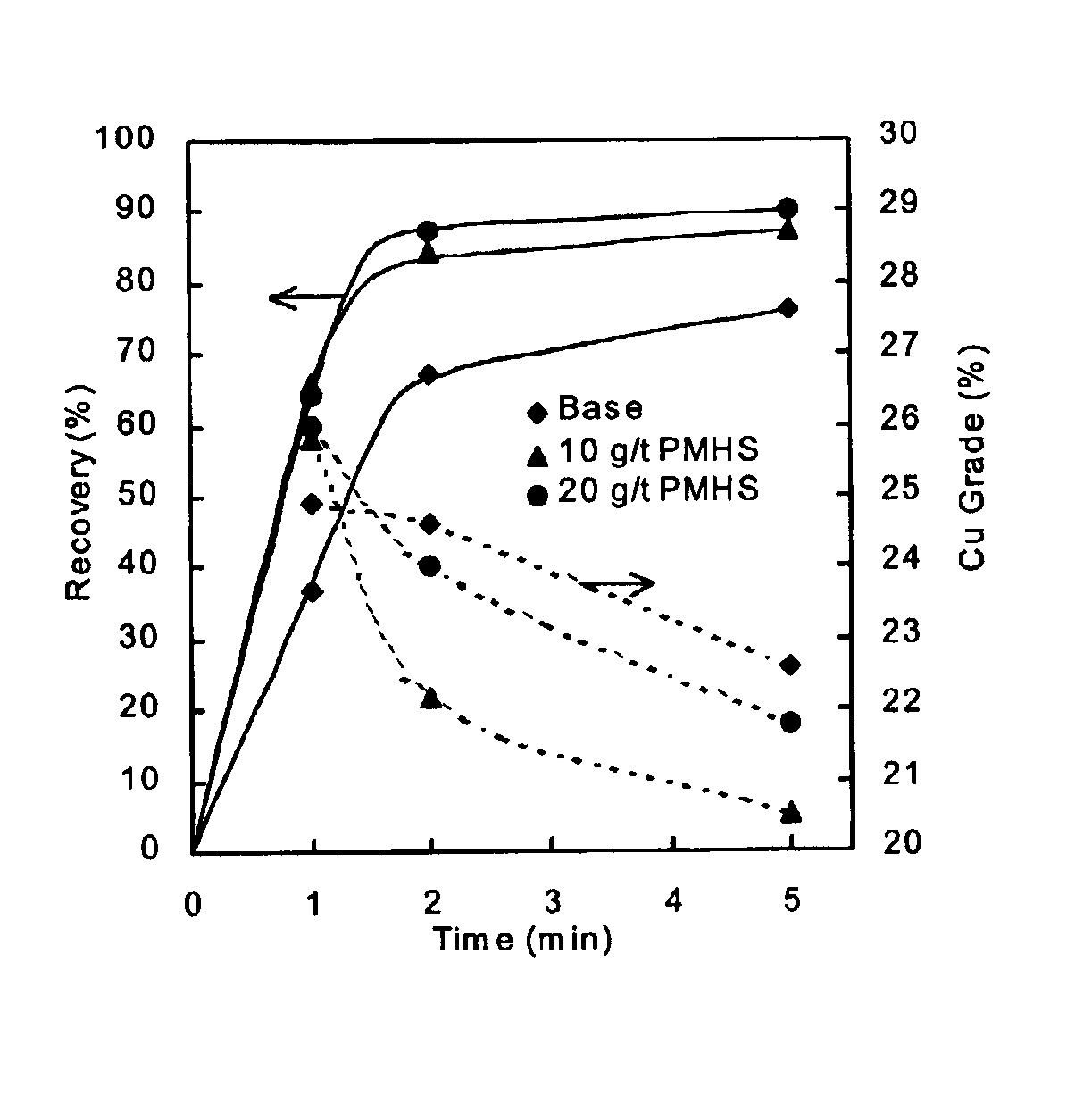

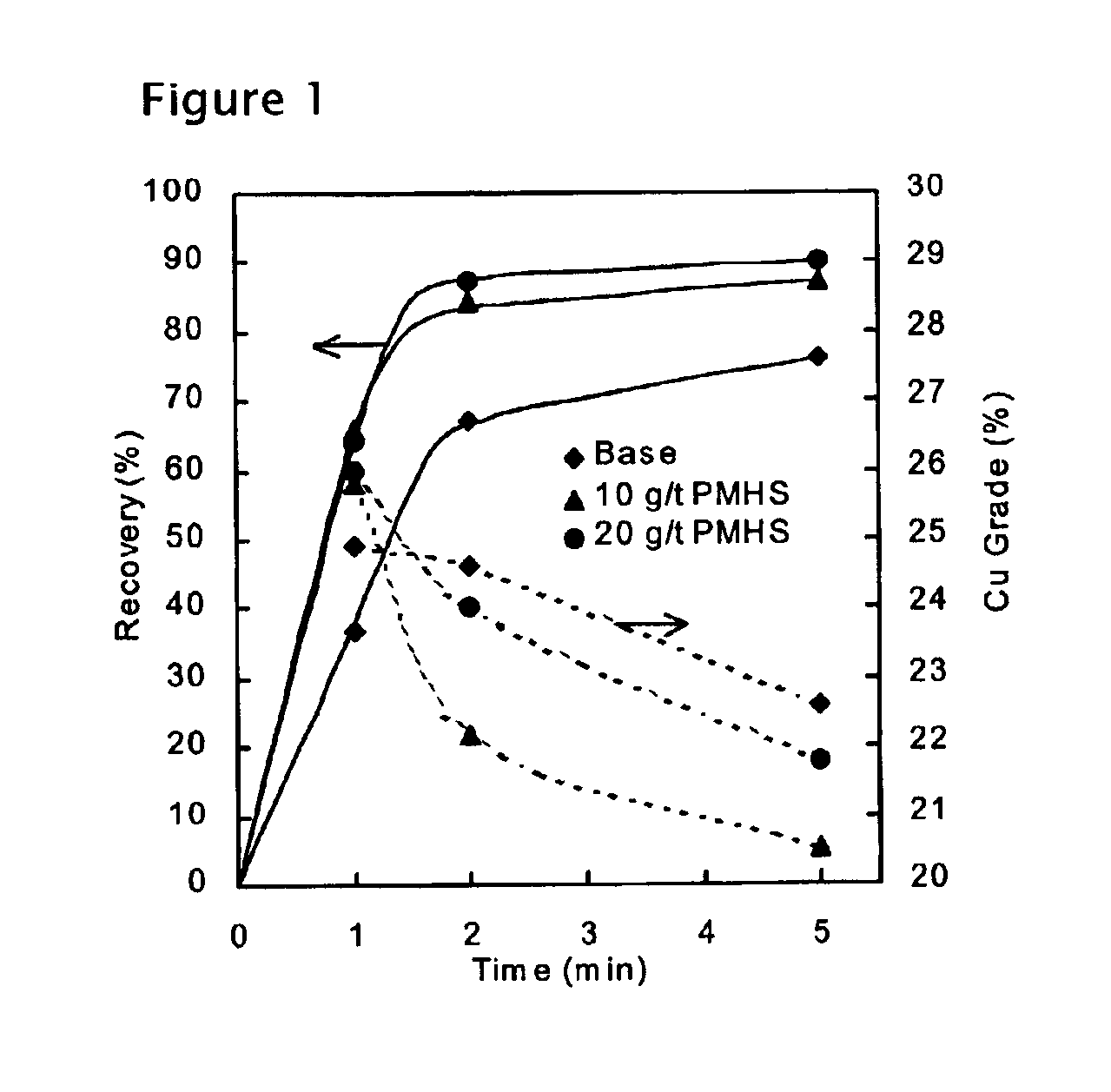

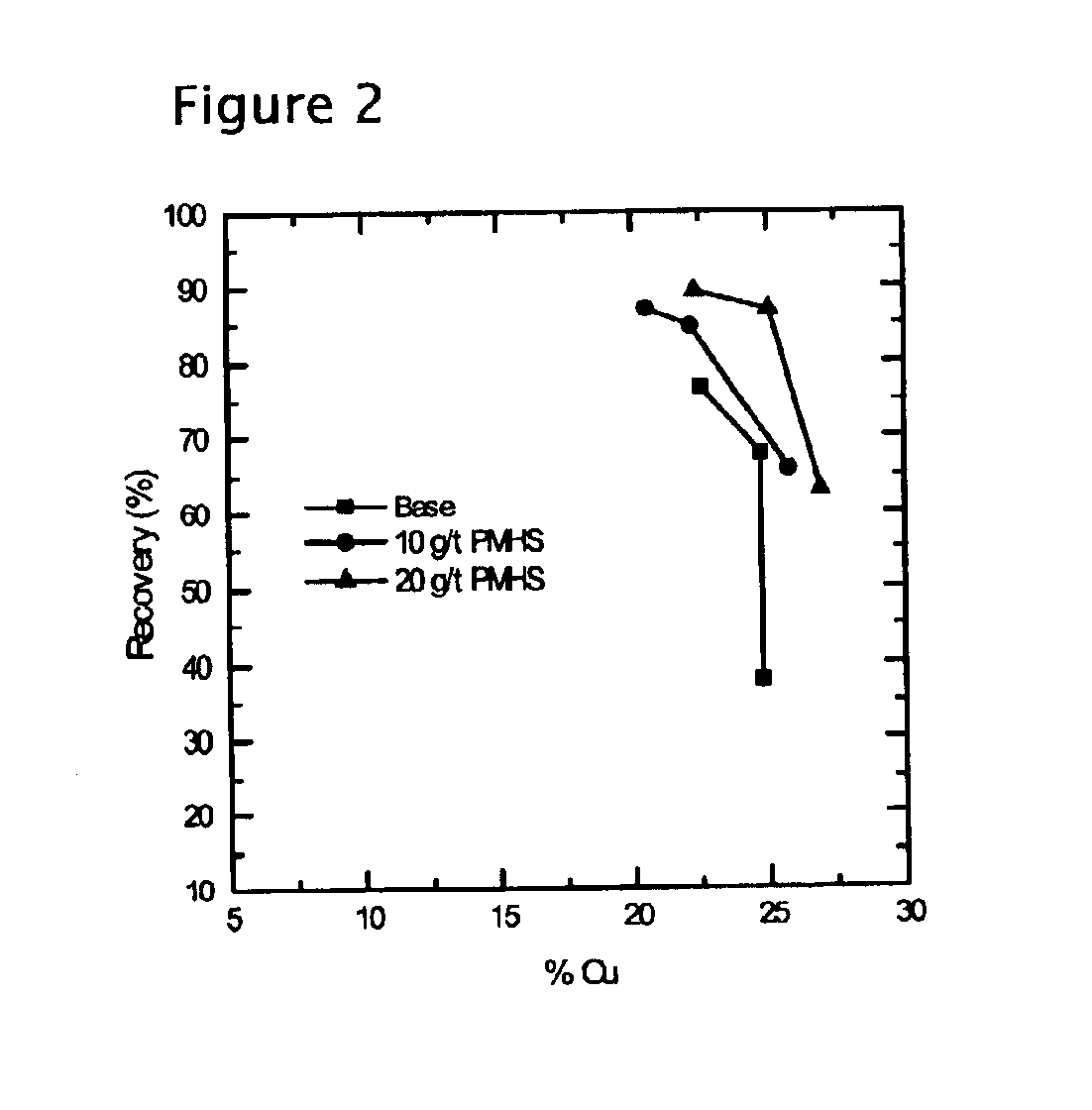

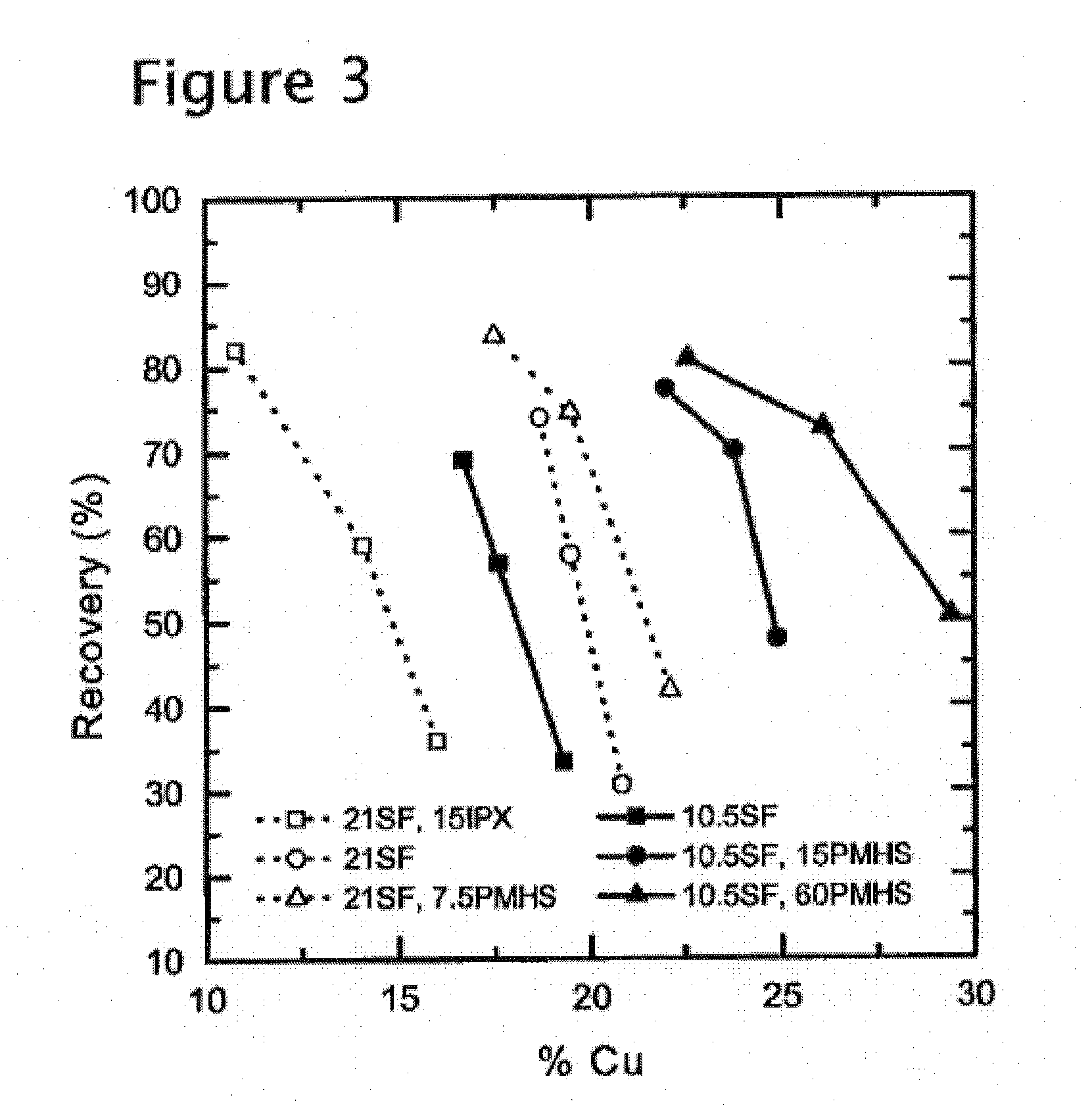

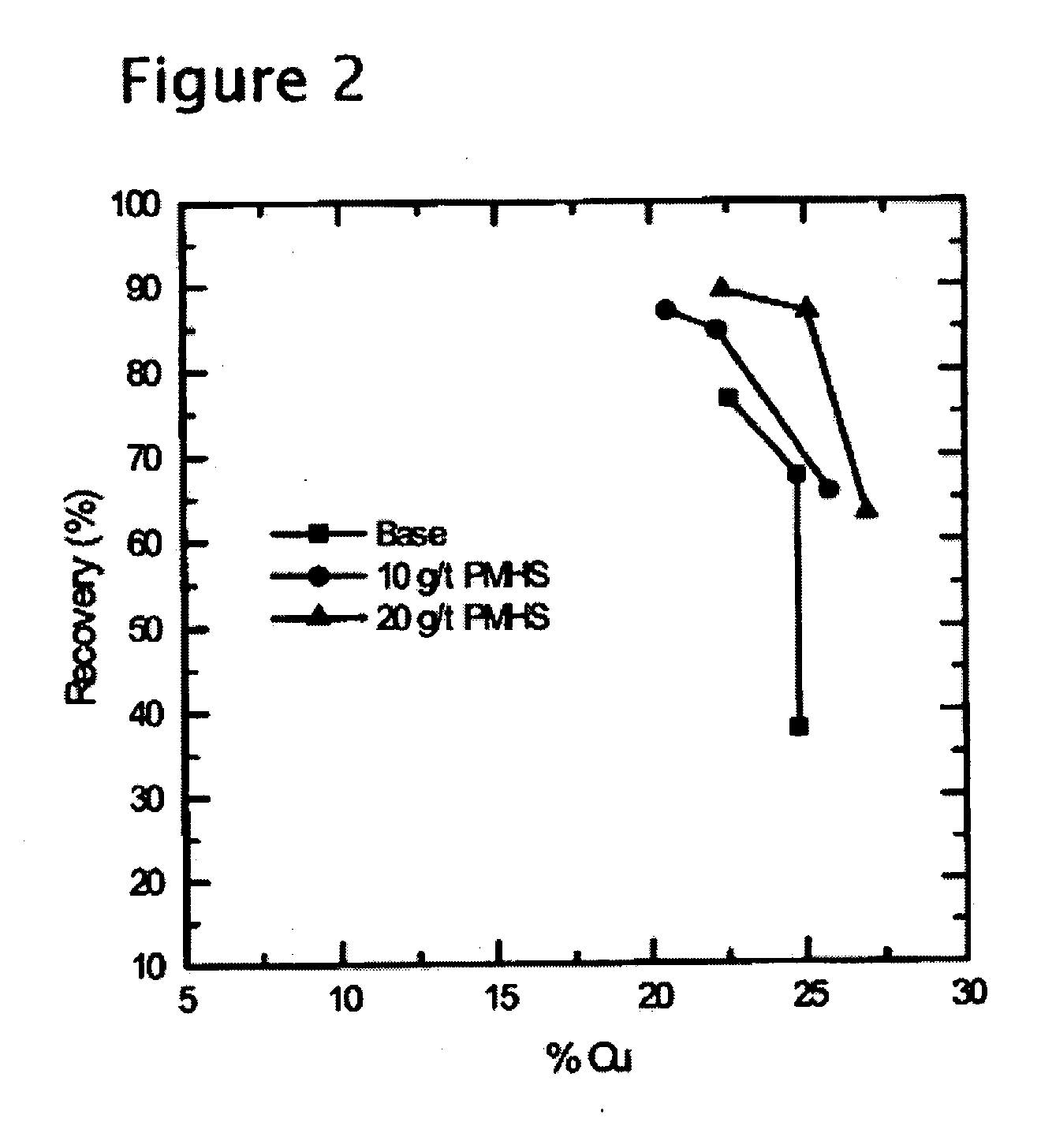

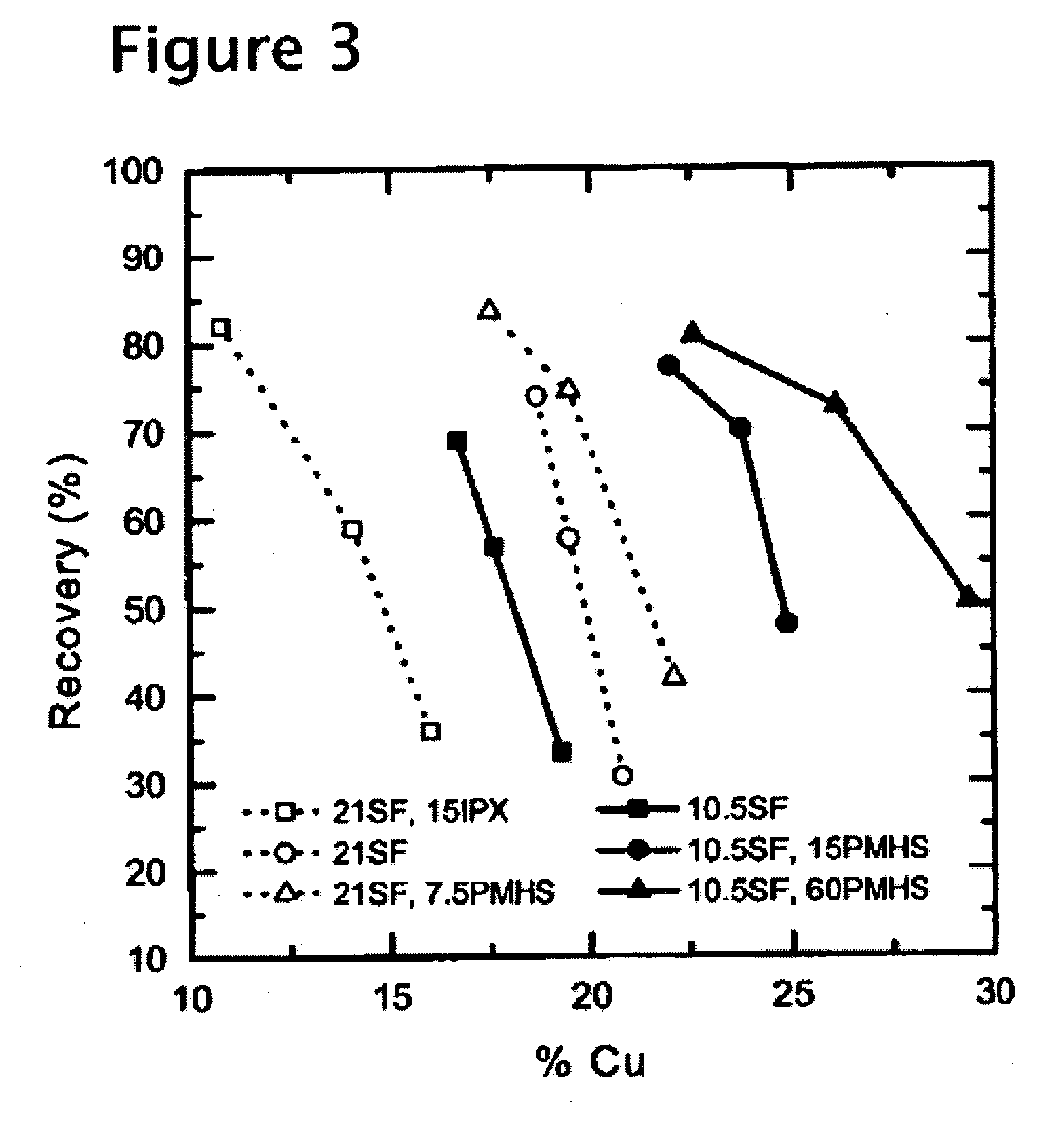

Methods of increasing the rate of separating hydrophobic and hydrophilic particles by flotation have been developed. They are based on using appropriate reagents to enhance the hydrophobicity of the particles to be floated, so that they can be more readily collected by the air bubbles used in flotation. The hydrophobicity-enhancing reagents include low HLB surfactants, naturally occurring lipids, modified lipids, and hydrophobic polymers. These methods can greatly increase the rate of flotation for the particles that are usually difficult to float, such as ultrafine particles, coarse particles, middlings, and the particles that do not readily float in the water containing large amounts of ions derived from the particles. In addition, new collectors for the flotation of phosphate minerals are disclosed.

Owner:MINERAL & COAL TECH

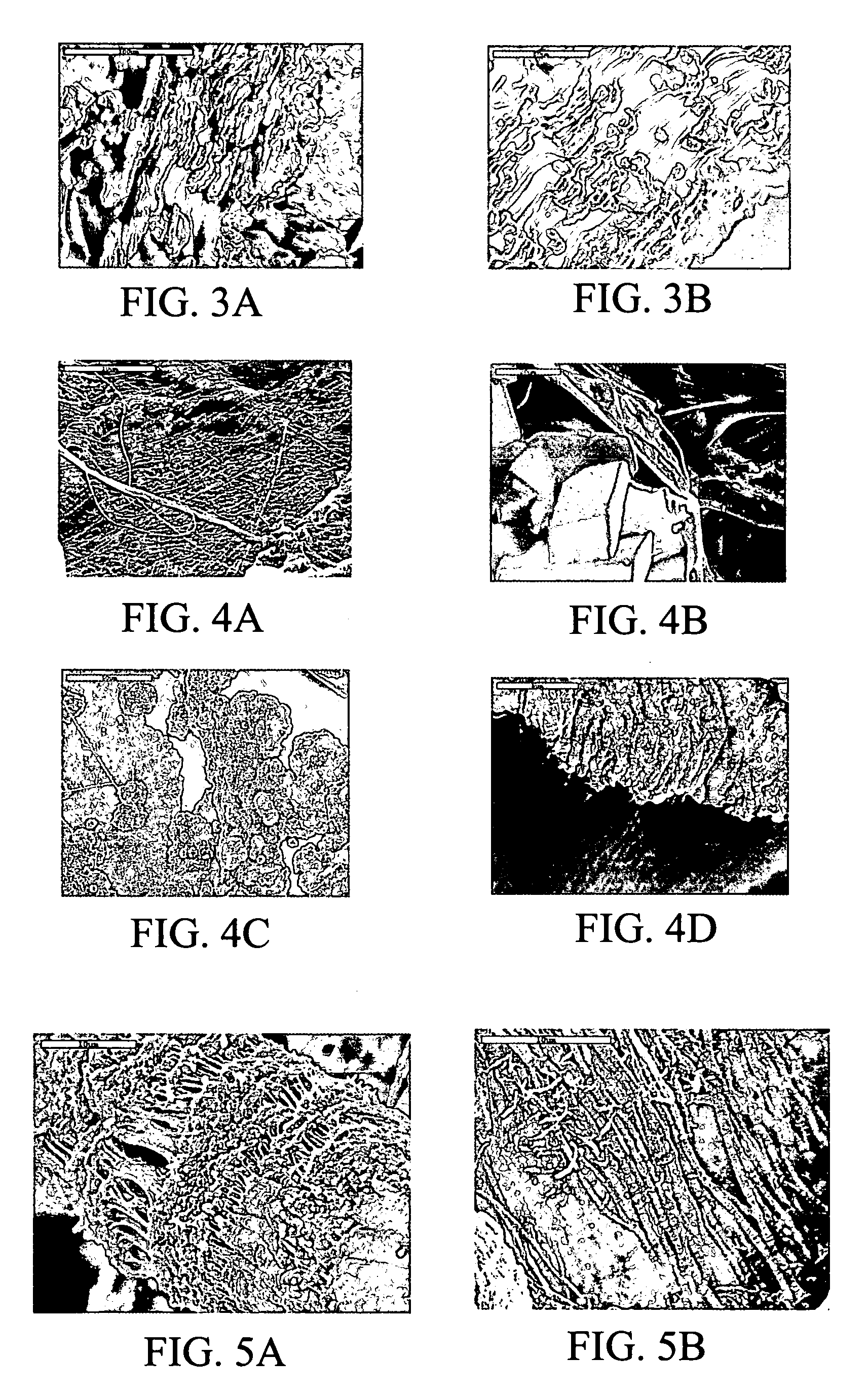

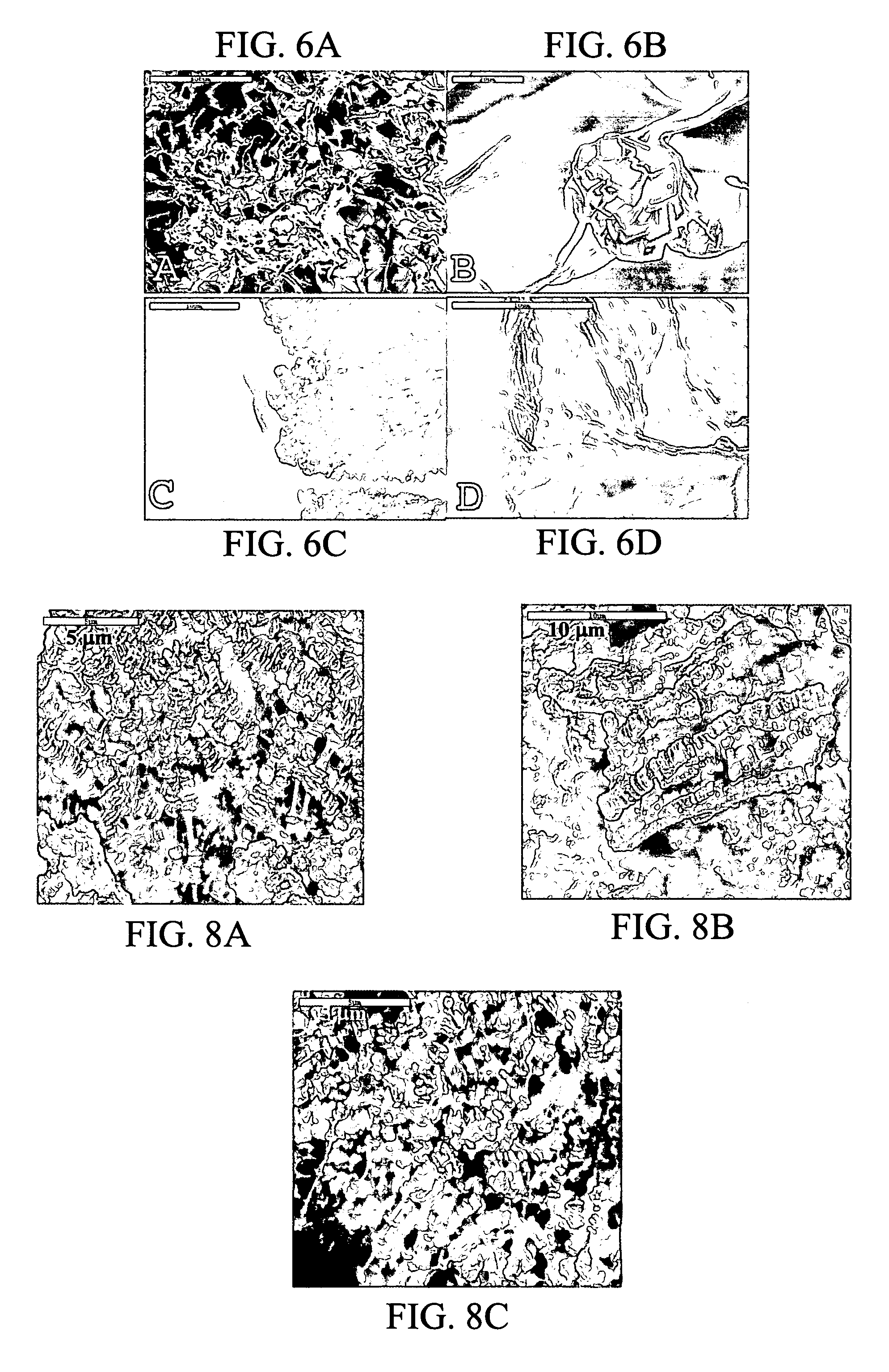

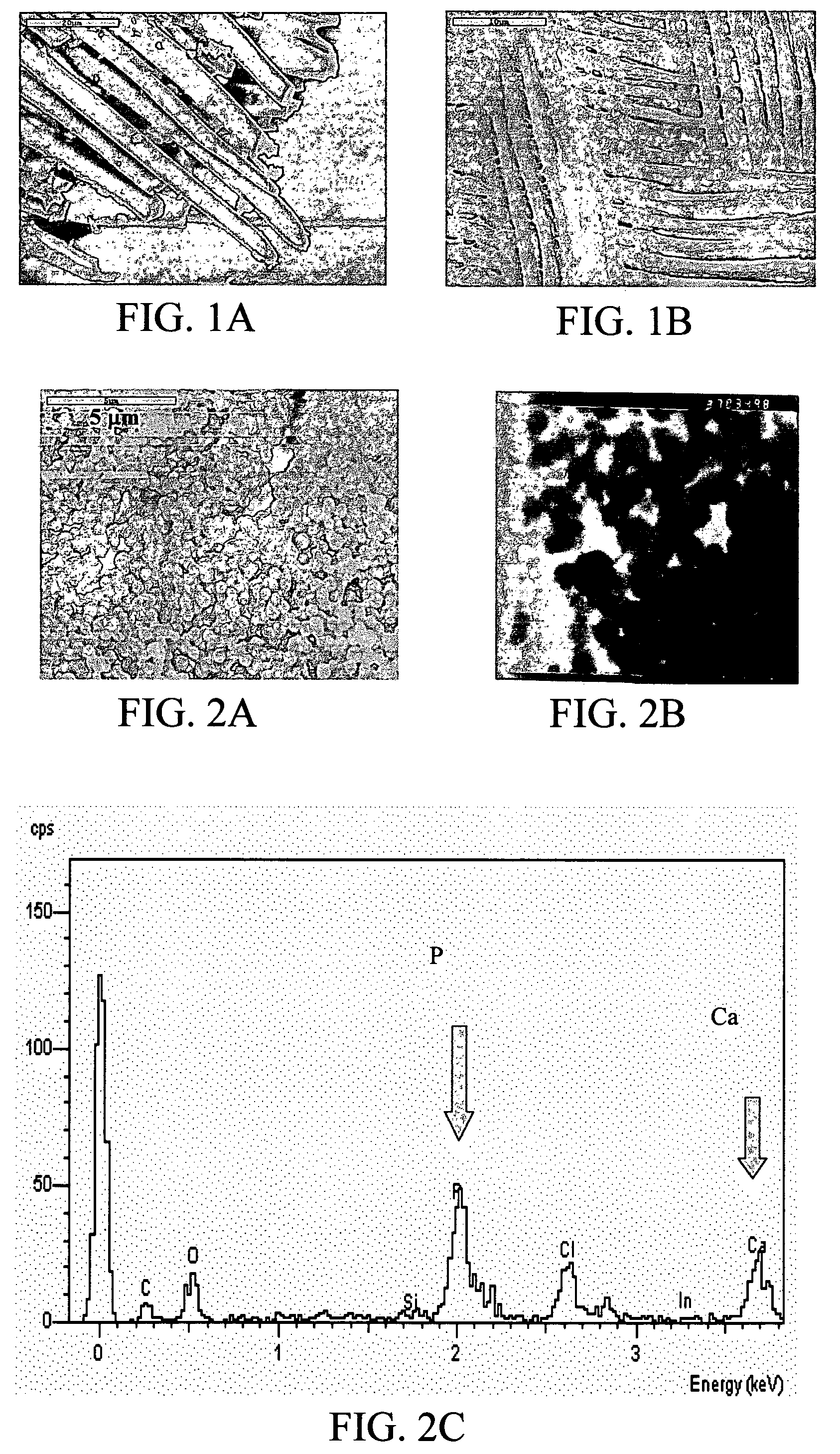

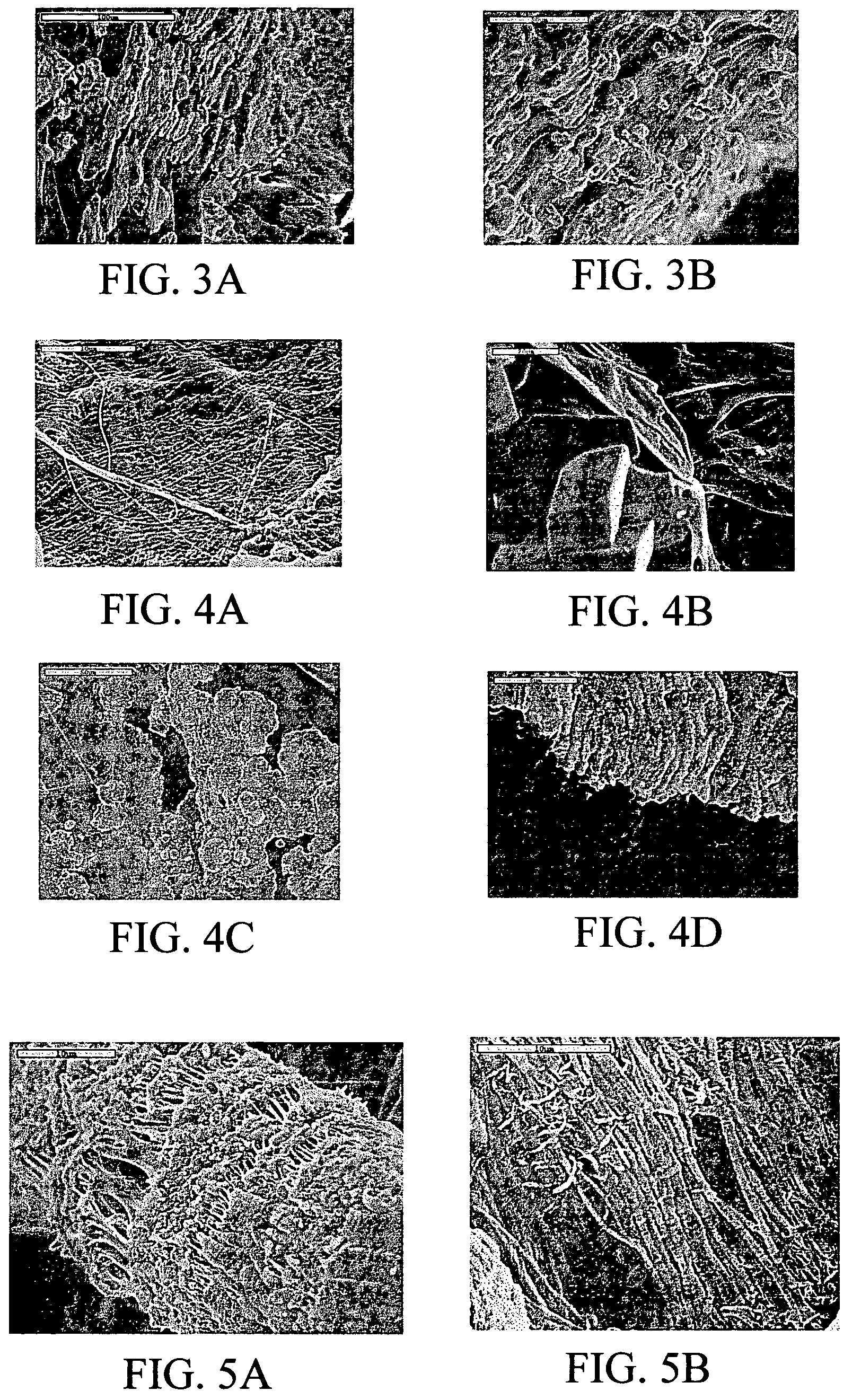

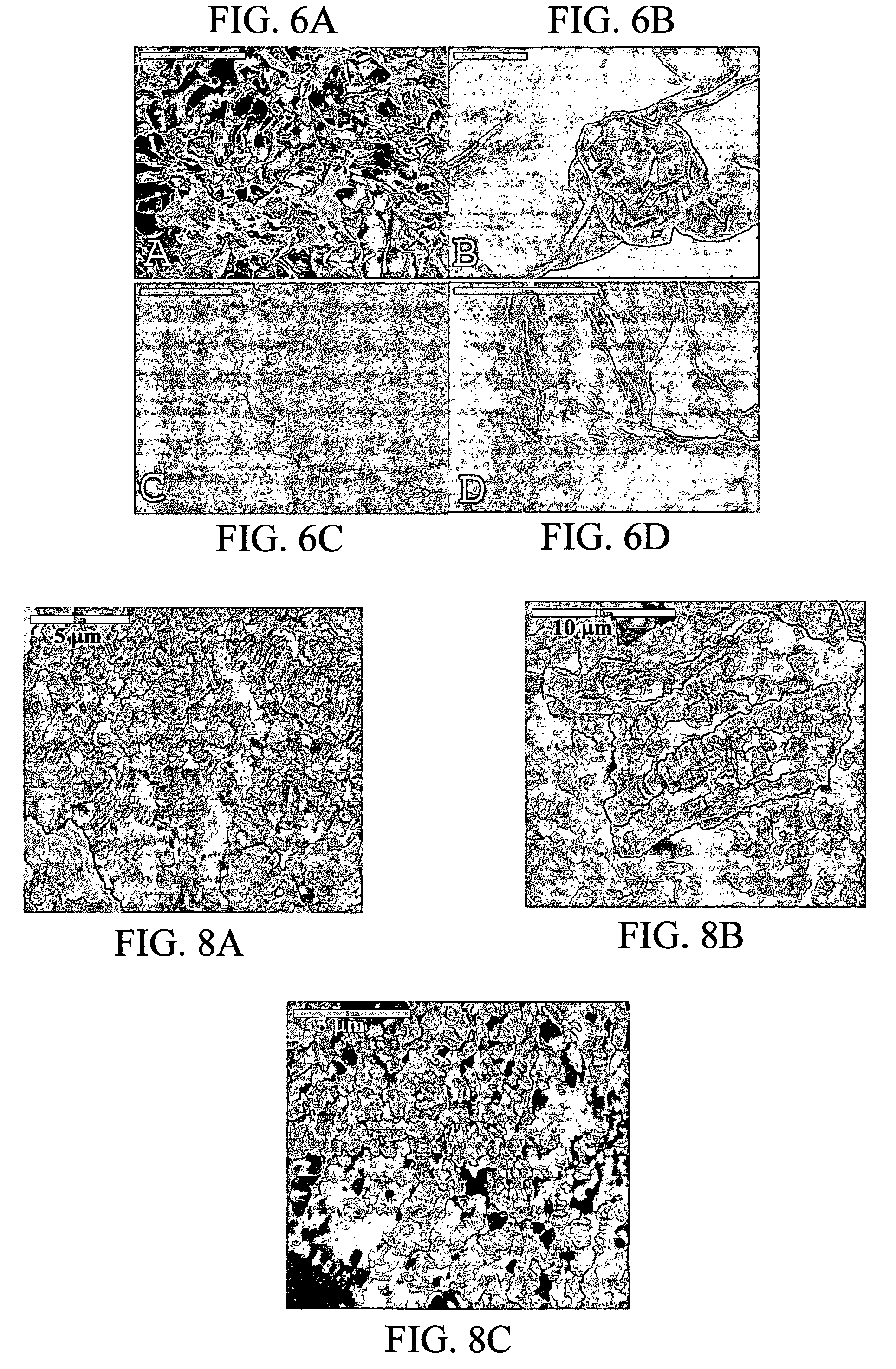

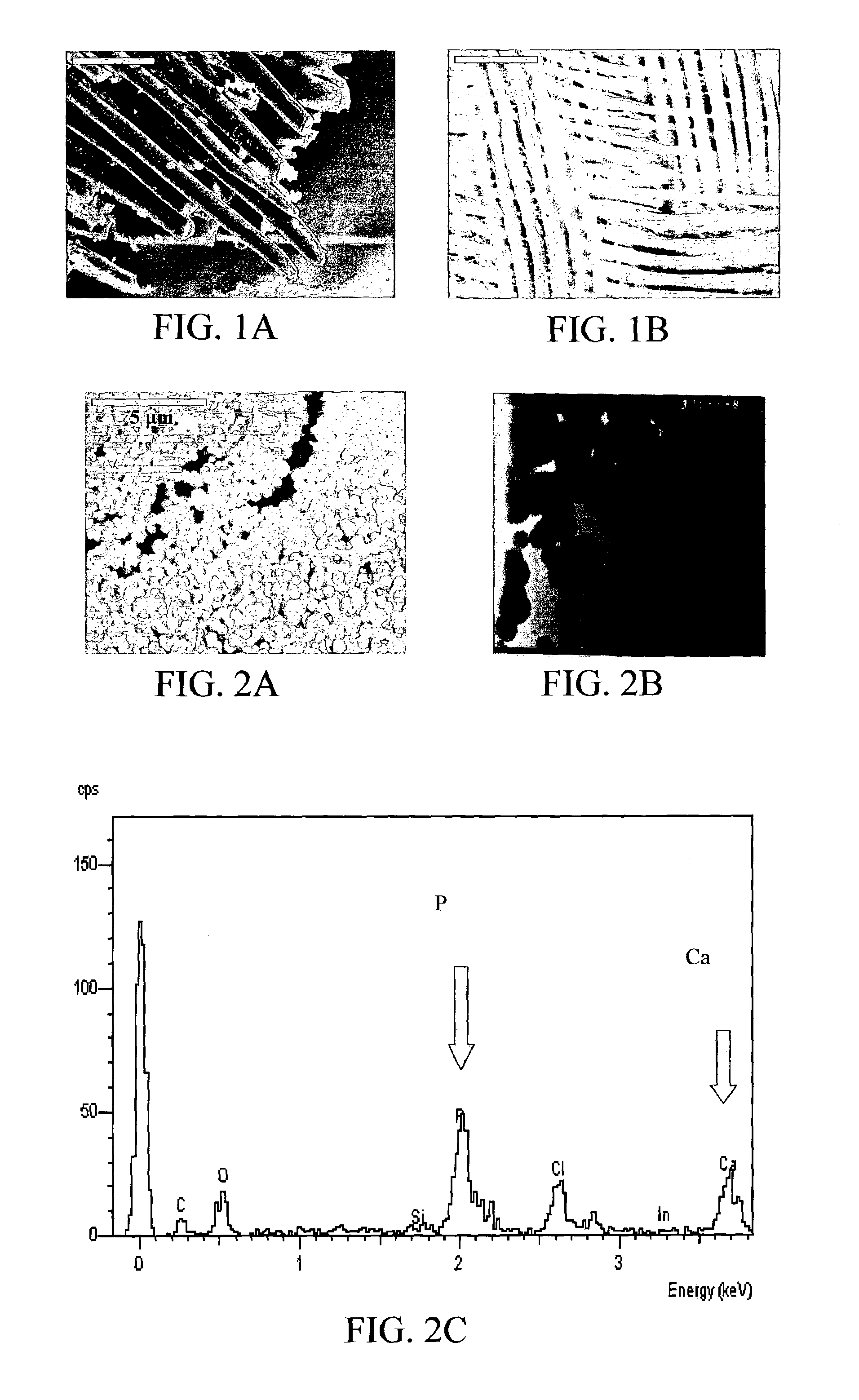

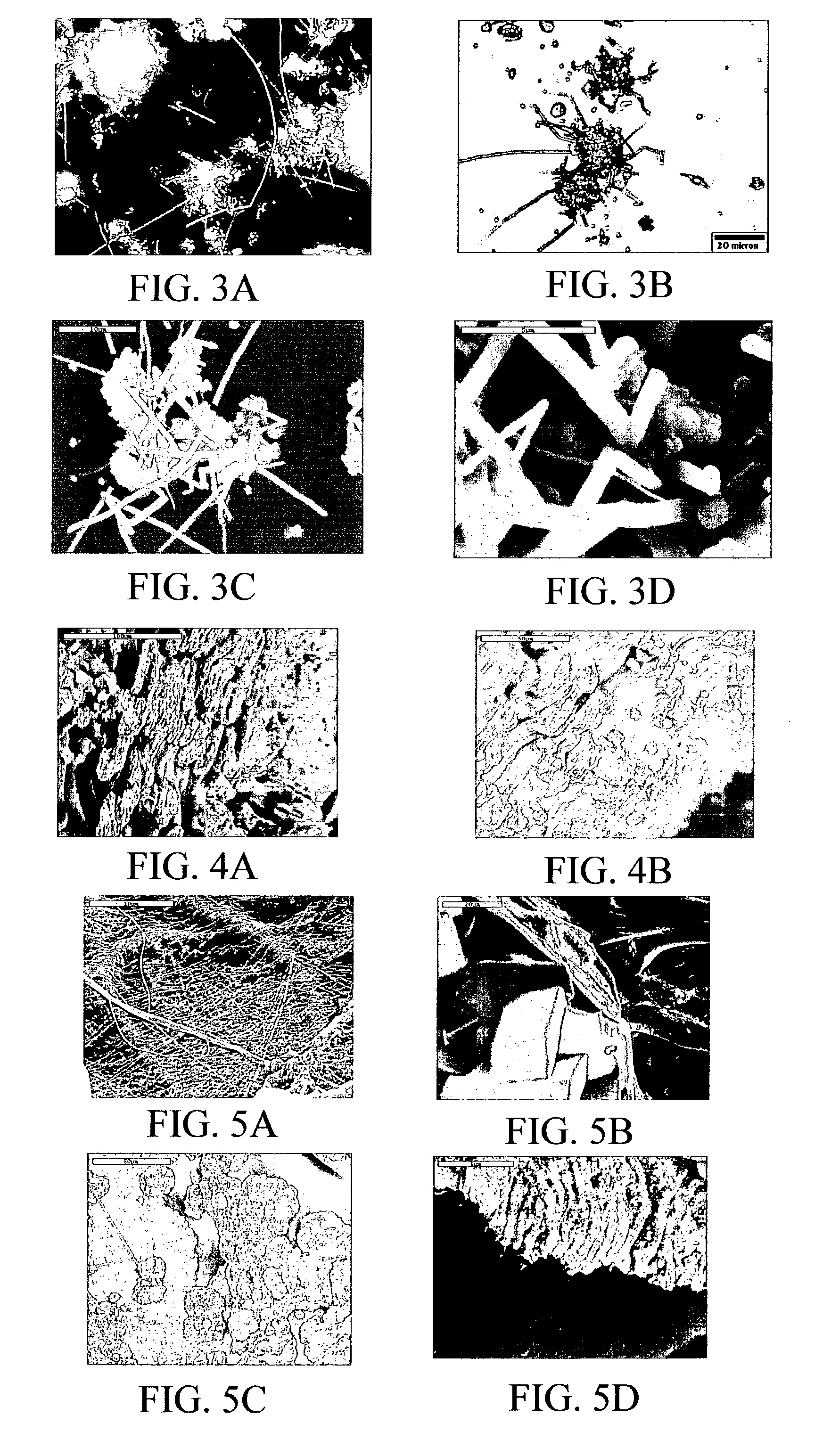

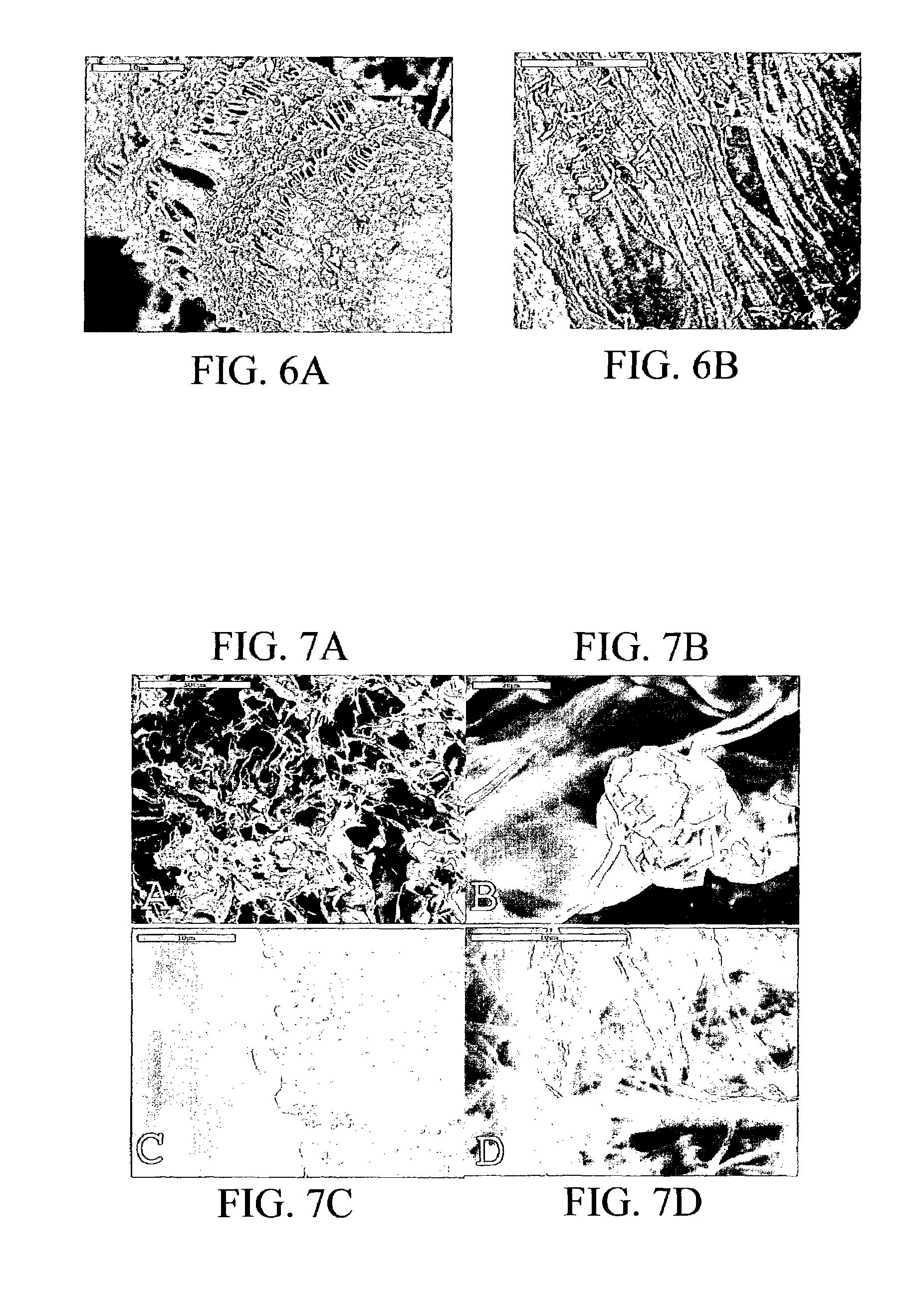

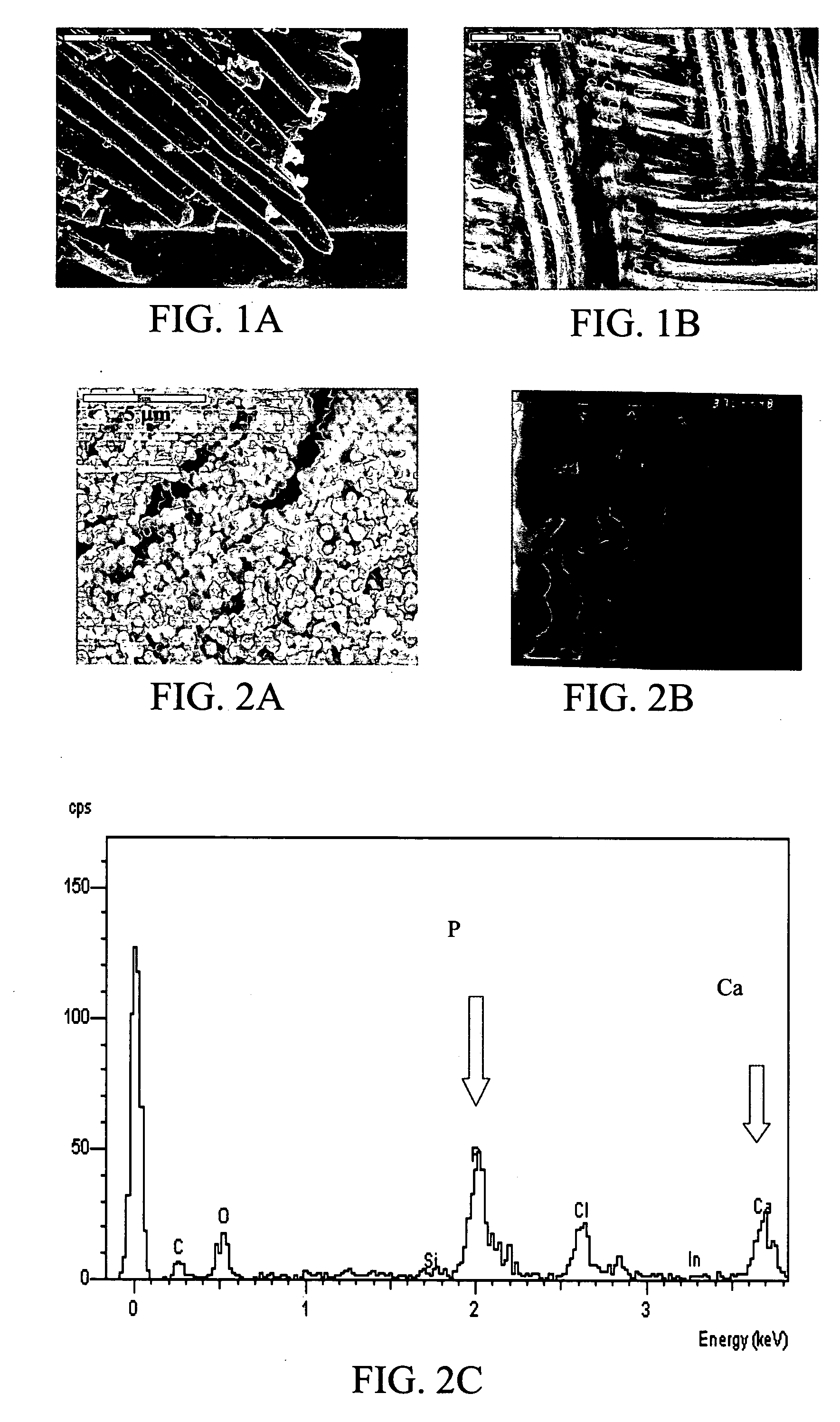

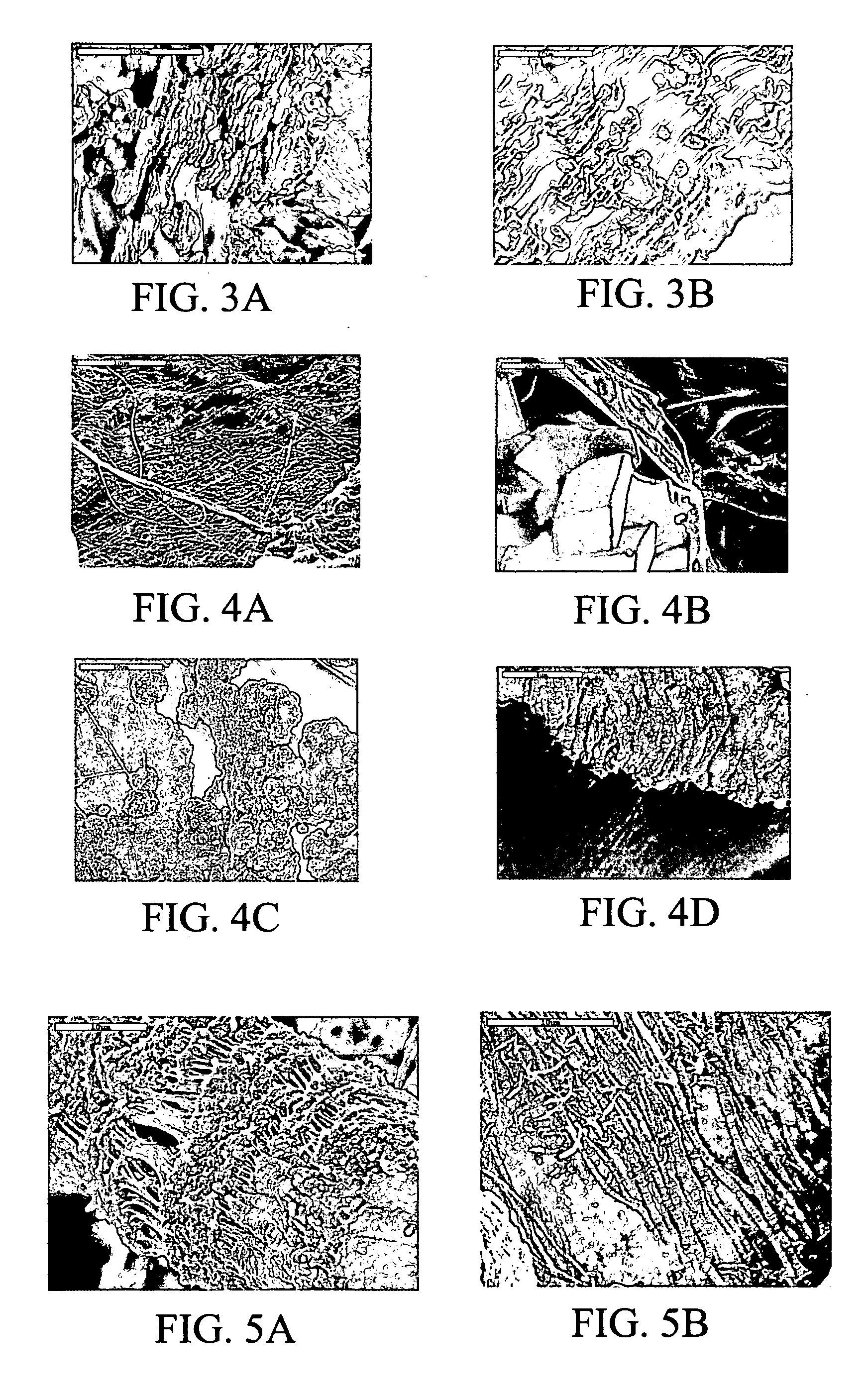

Biomimetic organic/inorganic composites, processes for their production, and methods of use

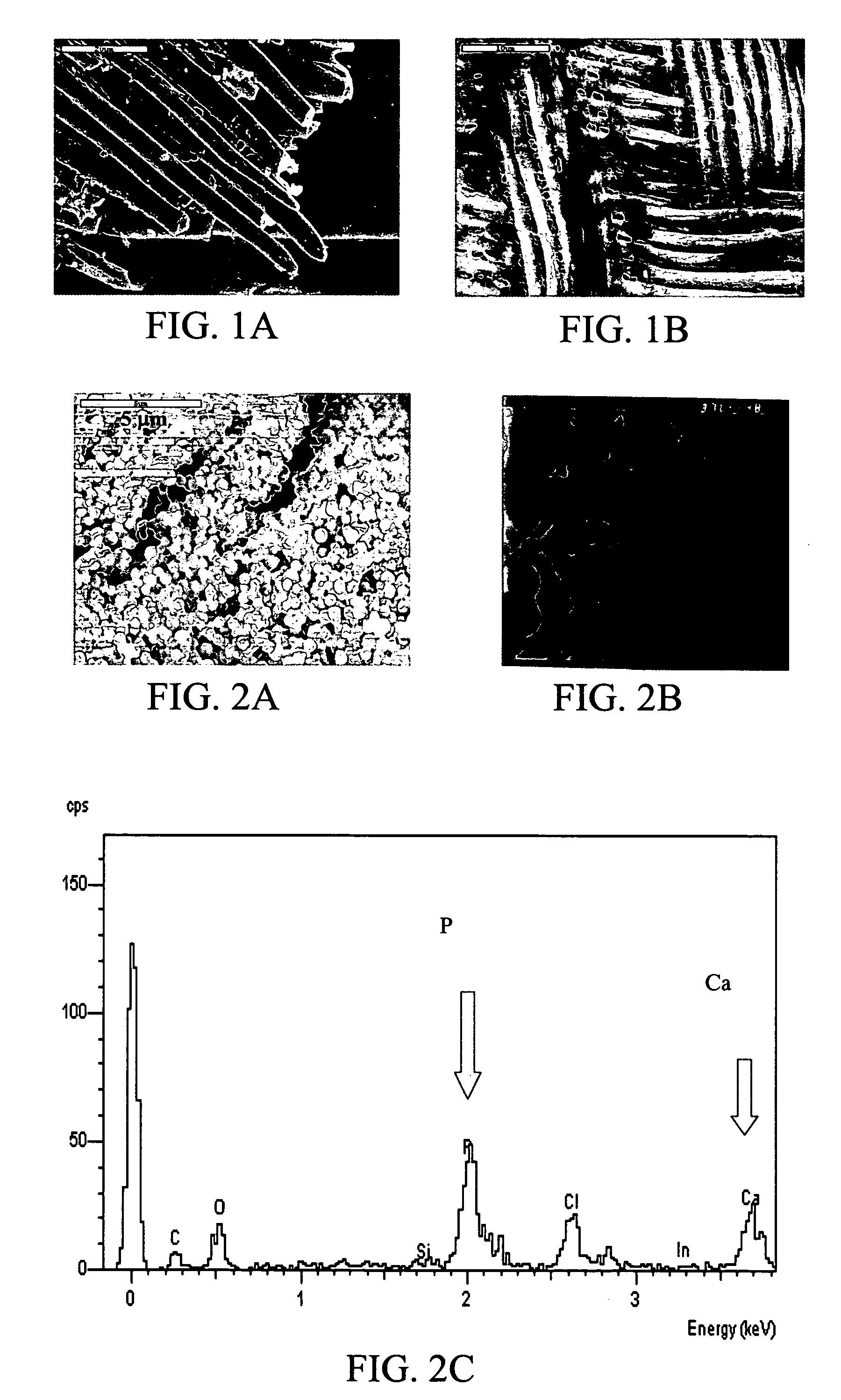

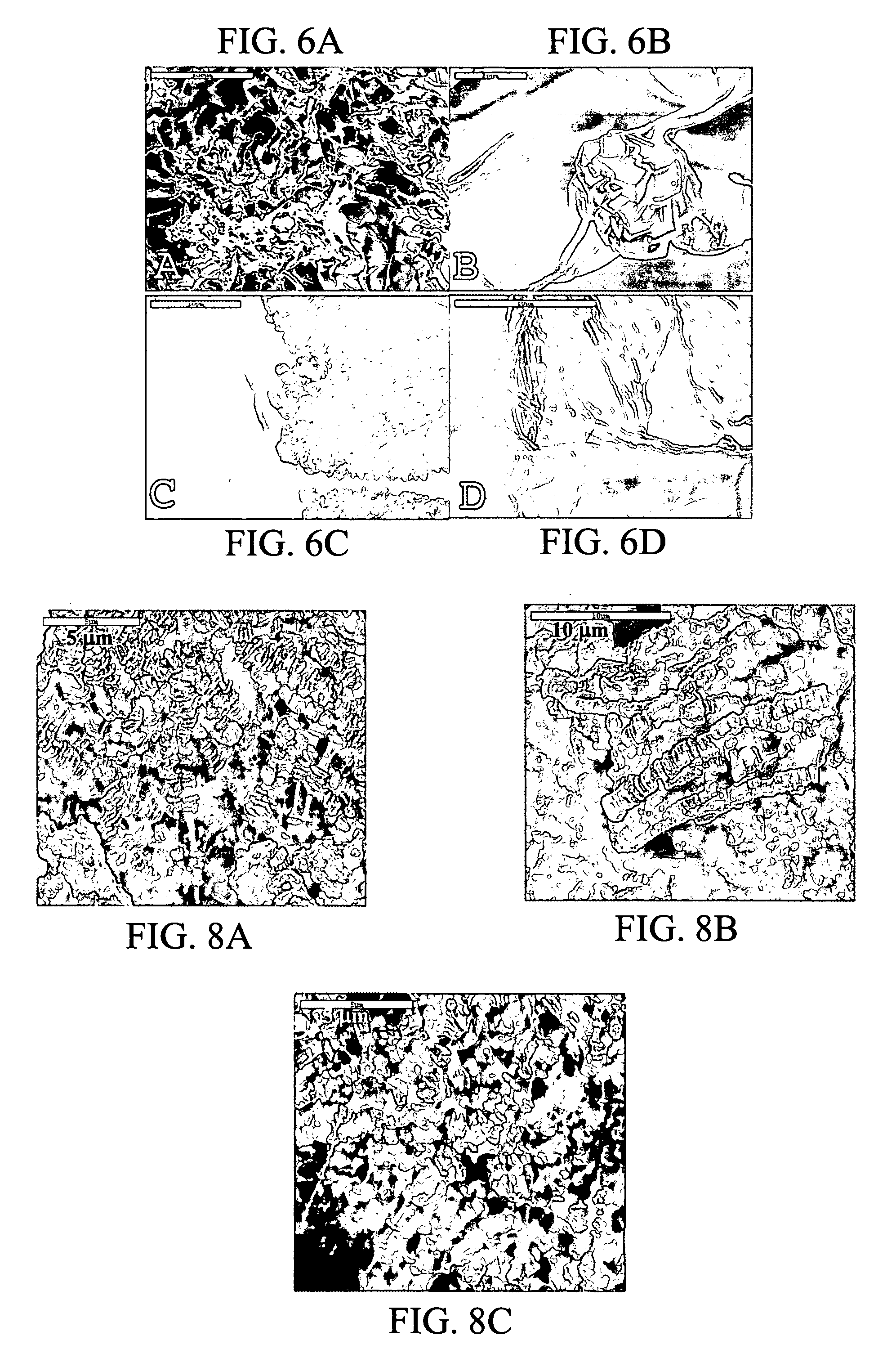

The subject invention concerns a composite comprising an organic fluid-swellable, fibrous matrix, such as collagen, and a mineral phase, such as calcium carbonate or phosphate mineral phase, for use as a biomimetic of bone. In another aspect, the subject invention concerns a process for making a composite involving the inclusion of acidic polymers to a supersaturated mineralizing solution, in order to induce an amorphous liquid-phase precursor to the inorganic mineral, which is then absorbed (pulled by capillary action) into the organic matrix. Advantageously, once solidified, a high mineral content can be achieved, with the inorganic mineral crystals embedded within the collagen fibers (intrafibrillarly) and oriented such that they are aligned along the long axes of the fibers of the organic matrix, thereby closely mimicking the natural structure of bone. The present invention further concerns a method of treating a patient suffering from a bone defect by applying a biomimetic composite to the bone defect site.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

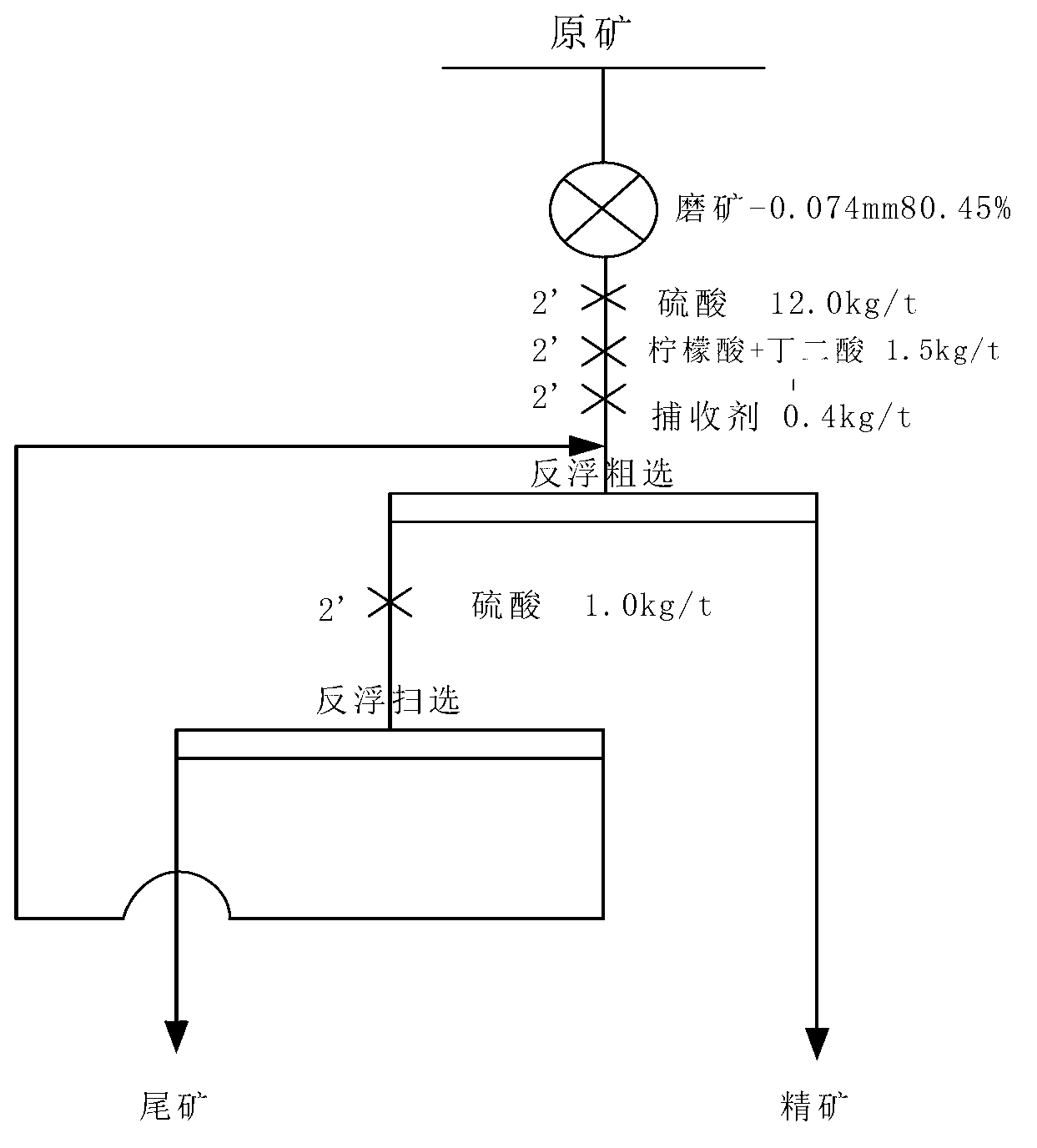

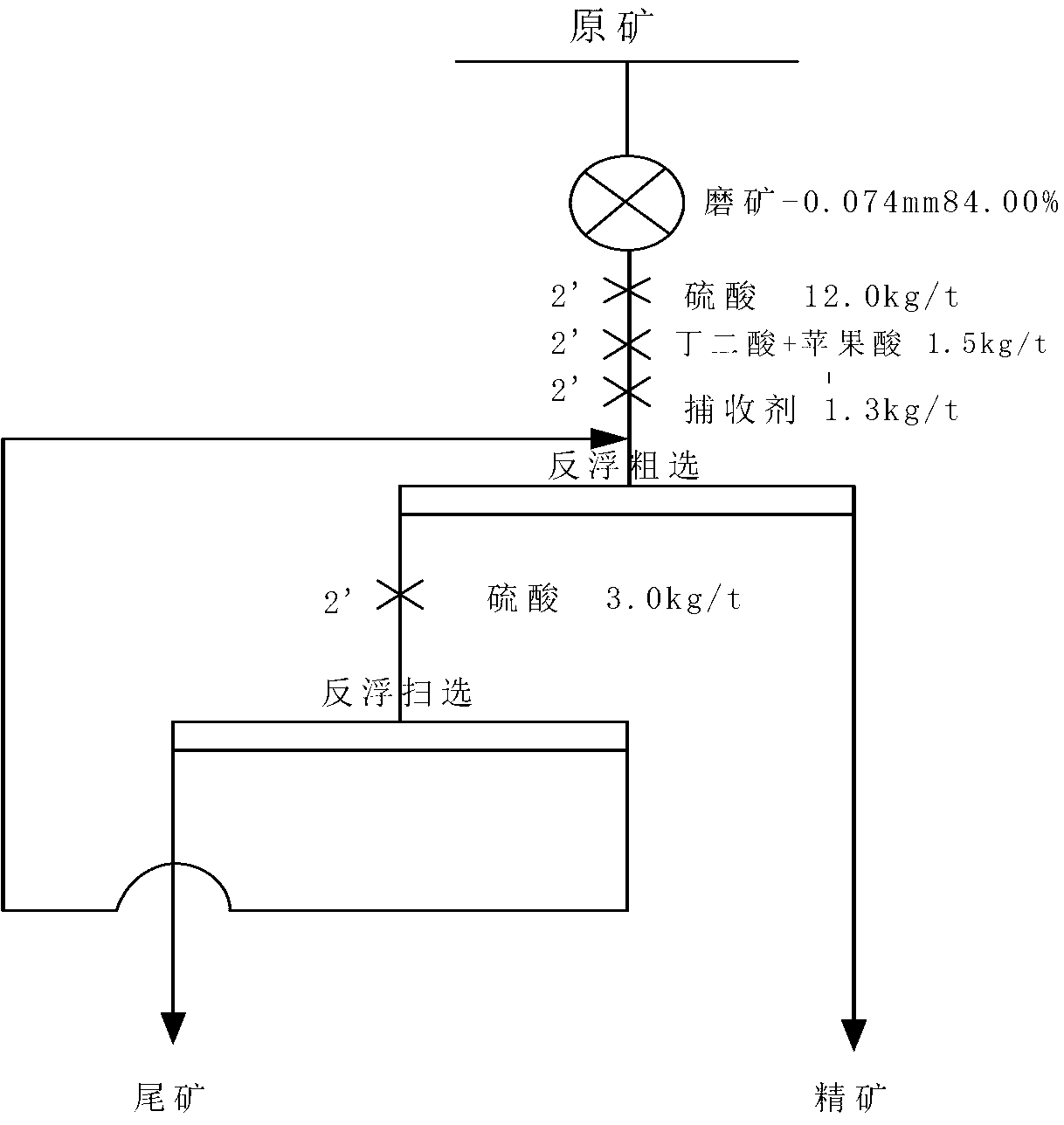

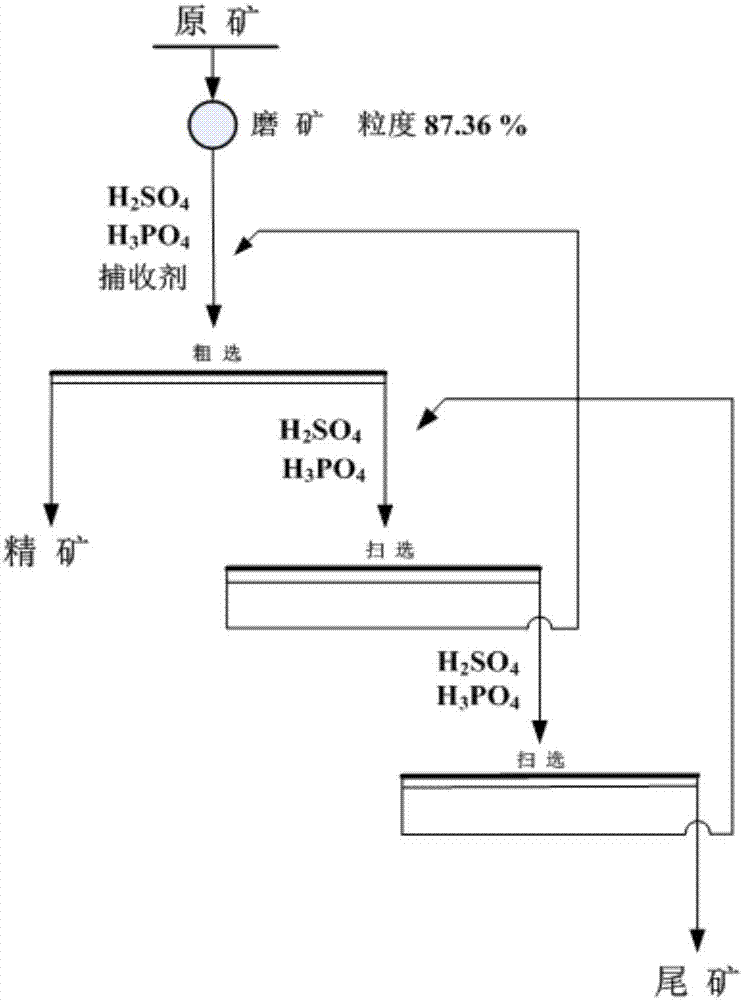

Phosphorite reverse flotation process

ActiveCN103212484ANo pollution in the processEfficient separationFlotationOrganic acidPhosphoric acid

The invention relates to a phosphorite reverse flotation process which comprises the following steps: after carrying out ore crushing, ore grinding and size mixing on phosphorite, enabling the obtained product to enter the reverse flotation process, wherein ore pulp obtained after size mixing is added with sulfuric acid or phosphoric acid to form a regulator and an inhibitor and then is added with micromolecule organic acid to form a combined inhibitor for inhibiting phosphate minerals; carrying out reverse flotation to separate out carbonate minerals by using fatty acids or fatty acid soaps as a collecting agent so as to obtain high-grade low-magnesium phosphate concentrates. The phosphorite reverse flotation process has the following advantage that the micromolecule organic acid inhibitor is adopted to implement effective separation of collophanite and dolomite, so that the grade of the phosphate concentrates is improved, the grade of tailings is reduced and the recovery rate can be improved. Meanwhile, application of phosphoric acid and derivatives thereof to phosphorite reverse flotation is replaced, so that phosphorus resources are saved, service time of phosphate rock resources is prolonged and the defects in the prior art are overcome.

Owner:远安县燎原矿业有限责任公司

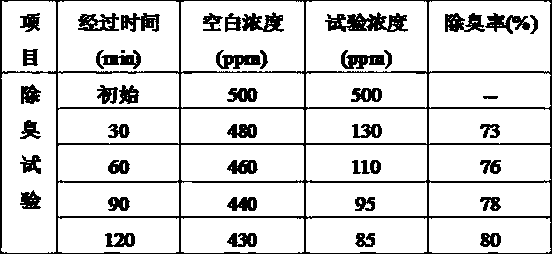

Anti-microbial and deodorizing coating additive and preparation method thereof

ActiveCN104130619ASimple preparation processAchieve antibacterial and deodorizing effectAntifouling/underwater paintsPaints with biocidesWater basedHazardous substance

The invention relates to an anti-microbial and deodorizing coating additive and a preparation method thereof. The anti-microbial and deodorizing coating additive is composed of an inorganic oxide and a phosphate mineral carrier which wrapping the inorganic oxide, wherein a weight ratio of the inorganic oxide to the phosphate mineral carrier is 1:2. The anti-microbial and deodorizing coating additive can be used for preparing a coating in a manner of being mixed with resin, pigment filling materials and solvents. The coating can be coated on surfaces of metal, plastic, walls or woodwares and can form a uniform paint film coating through drying and curing. The coating can decompose various indoor harmful gas or harmful substances and can purify indoor air so that an anti-microbial and deodorizing effect is achieved. The resin, which has a gluing effect, can be selected from a water-based system or an oil-based system. The solvent can be selected according to whether the water-based system or the oil-based system is selected. The solvent can be selected from, in an individual manner or a blended manner, alcohols, esters, ketones, ethers, organic acids and the like. The coating additive is simple in the preparation method and is suitable for being large-range popularized and applied.

Owner:GUANGDONG SUNJOY NEW ENERGY

Methods of Increasing Flotation Rate

Methods of increasing the rate of separating hydrophobic and hydrophilic particles by flotation have been developed. They are based on using appropriate reagents to enhance the hydrophobicity of the particles to be floated, so that they can be more readily collected by the air bubbles used in flotation. The hydrophobicity-enhancing reagents include low HLB surfactants, naturally occurring lipids, modified lipids, and hydrophobic polymers. These methods can greatly increase the rate of flotation for the particles that are usually difficult to float, such as ultrafine particles, coarse particles, middlings, and the particles that do not readily float in the water containing large amounts of ions derived from the particles. In addition, new collectos for the flotation of phosphate minerals are disclosed.

Owner:MINERAL & COAL TECH

Biomimetic organic/inorganic composites

The subject invention concerns a composite comprising an organic fluid-swellable, fibrous matrix, such as collagen, and a mineral phase, such as calcium carbonate or phosphate mineral phase, for use as a biomimetic of bone. In another aspect, the subject invention concerns a process for making a composite involving the inclusion of acidic polymers to a supersaturated mineralizing solution, in order to induce an amorphous liquid-phase precursor to the inorganic mineral, which is then absorbed (pulled by capillary action) into the organic matrix. Advantageously, once solidified, a high mineral content can be achieved, with the inorganic mineral crystals embedded within the collagen fibers (intrafibrillarly) and oriented such that they are aligned along the long axes of the fibers of the organic matrix, thereby closely mimicking the natural structure of bone. The present invention further concerns a method of treating a patient suffering from a bone defect by applying a biomimetic composite to the bone defect site.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

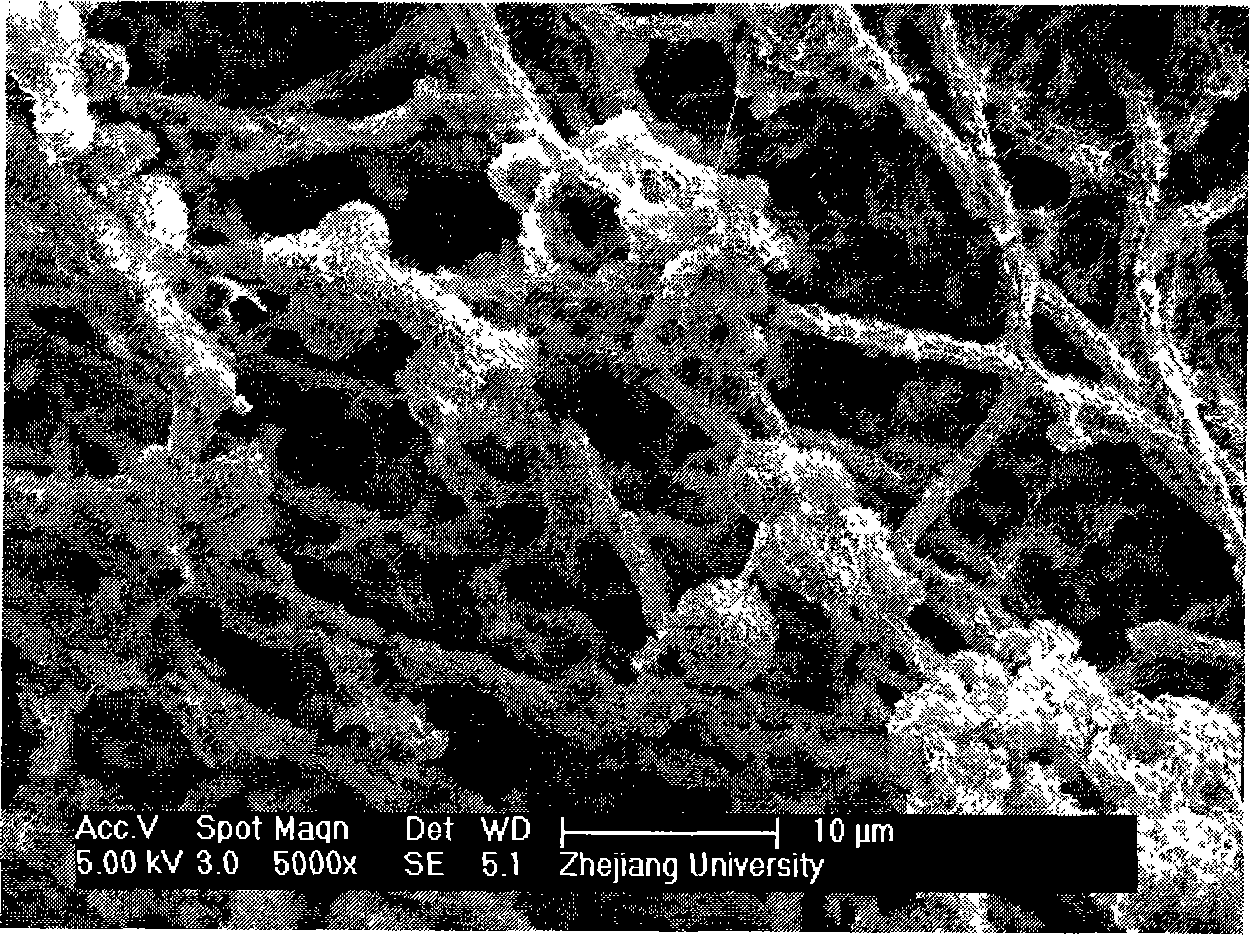

Method for preparing similar bone bioactivity coatings medical material by galvano-chemistry method

InactiveCN101156963AThe preparation process conditions are simpleEfficient preparation process conditionsElectrolytic inorganic material coatingElectrolysisApatite

The invention discloses bone-like bioactive coating medical material which is prepared by adopting an electrochemical method. The invention adopts an electrolytic deposition method and imitates the forming process of a natural bone. Electrolyte solution contains calcium, a phosphorous compound and bone matrix collagen, a medical metal transplant body is taken as a working electrode, platinum is taken as a reference electrode, the electrode reaction causes partial pH value of the electrolyte solution around the medical metal transplant body to ascend, thereby leading collagen to be gelatinized, in cooperation with the deposition of calcium phosphate mineral, the bone-like bioactive coating is formed on the medical metal surface. Through the adoption of the invention method, the bioactive coating acquired on the surface of the metal transplant body is similar to the natural bone in the component and the structure, and has favorable biological activity, thus the disadvantages that the biological activity of the business use hydroxyapatite coating is limited, the required curing time is long, etc. are solved. The preparation process of the invention is simple, highly effective and easy to be industrialized.

Owner:ZHEJIANG UNIV

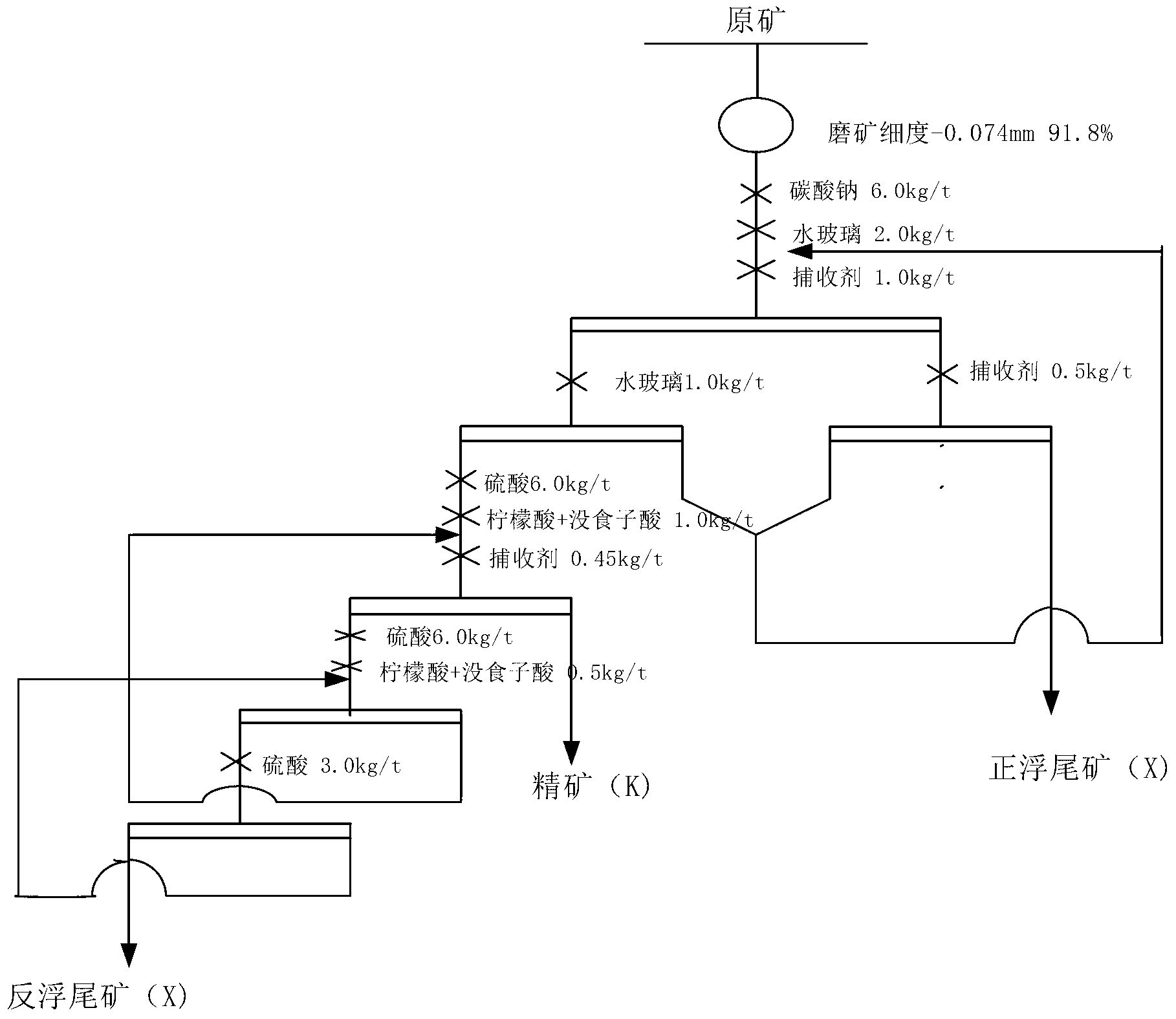

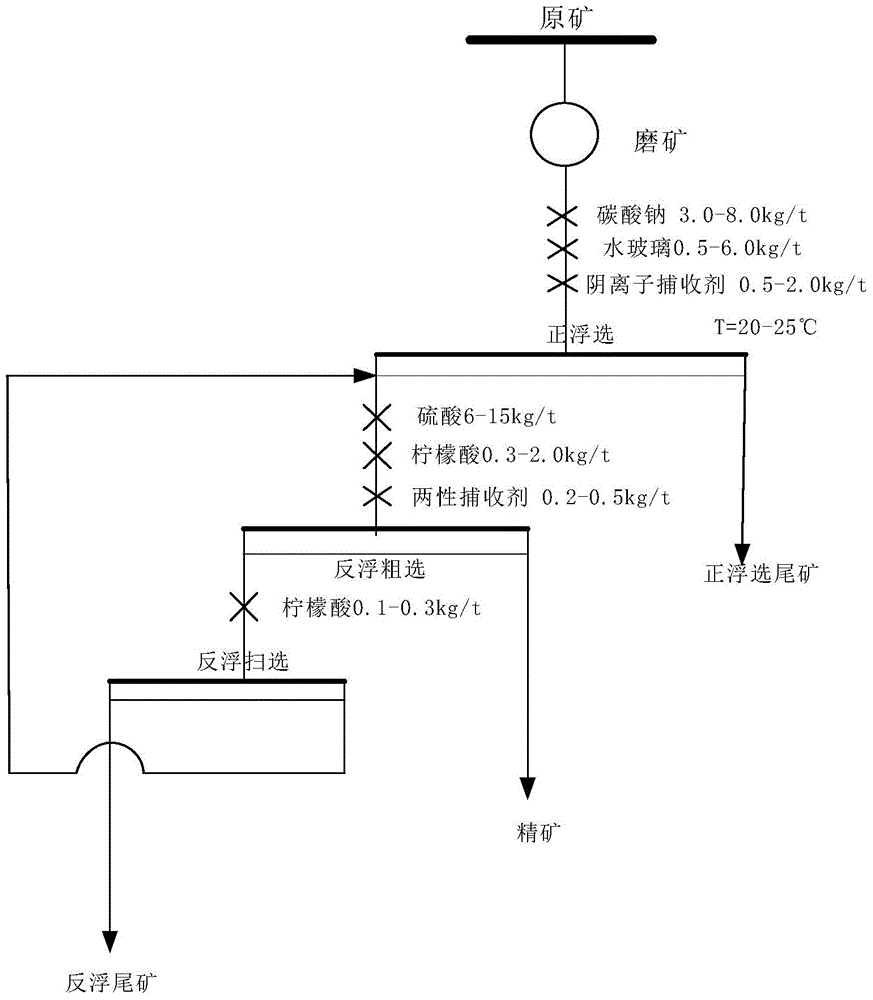

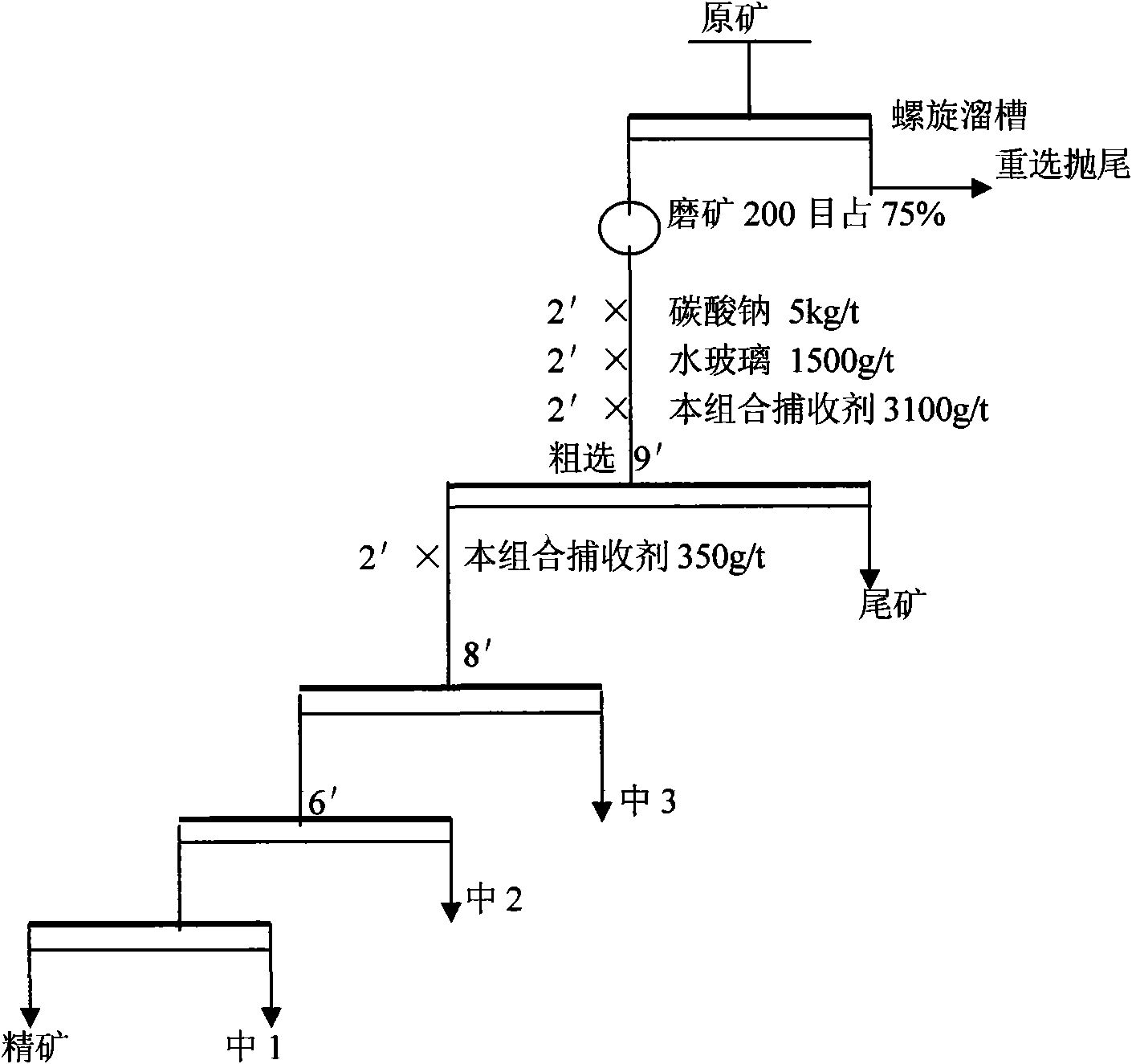

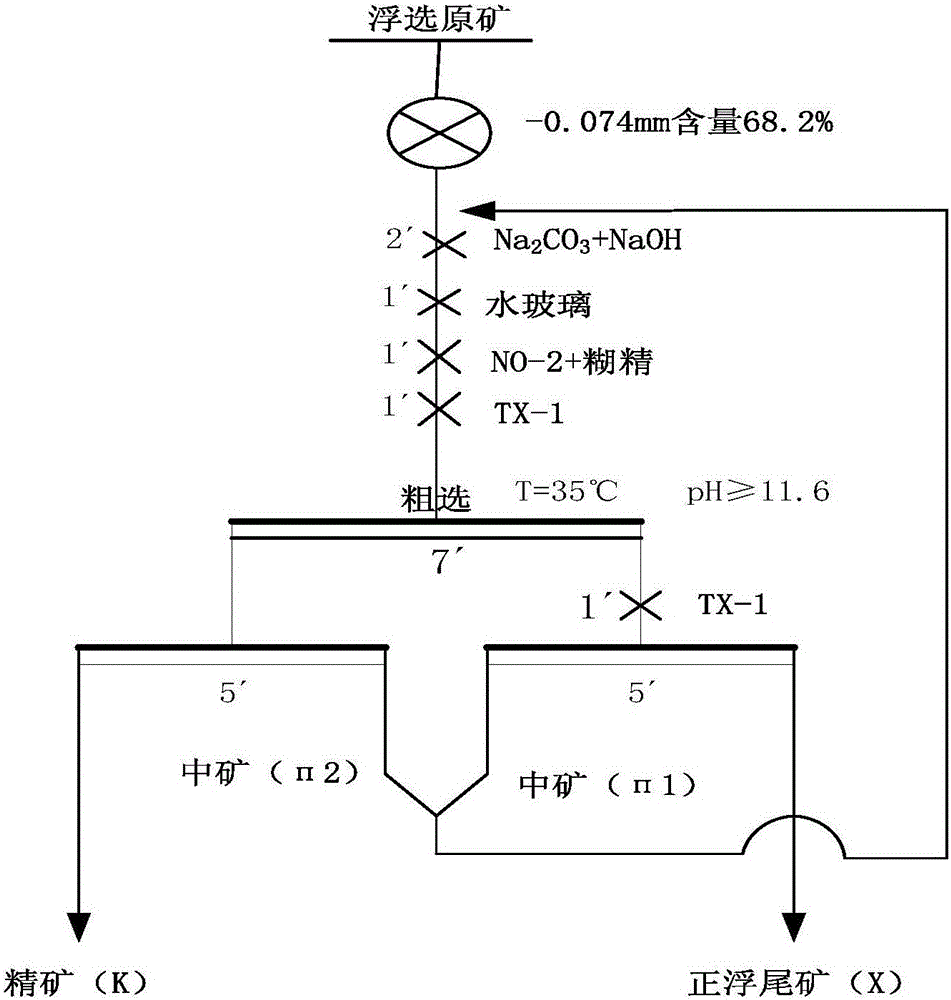

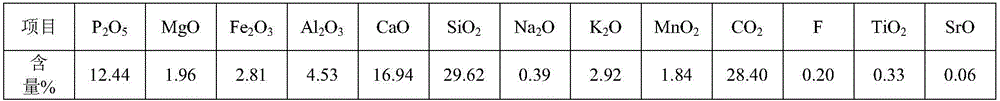

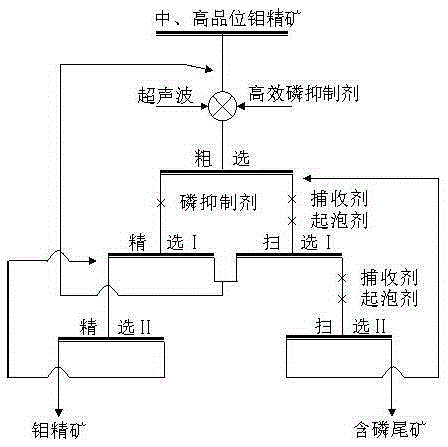

Silica-calcia low-grade collophanite positive and inverse floatation process

ActiveCN104907183AReduce contentRealize beneficiation and enrichmentFlotationCalcium in biologySesquioxide

The invention relates to a silica-calcia low-grade collophanite positive and inverse floatation process, which comprises the steps: 1 silica-calcia low-grade collophanite ores are broken up and grinded to enable phosphate minerals and gangue mineral monomers to dissociate, then are added with water to mix size, enter positive and inverse floatation, get rid of impurities in ores, and improve grade of phosphorite. Compared with the prior art, the silica-calcia low-grade collophanite positive and inverse floatation process has the advantages that the content of only one kind of gangue minerals can be reduced by adopting direct floatation and single inverse floatation, can reduce the contents of silicate minerals, carbonate minerals and iron and aluminum silicate minerals, can obtain low magnesium low power half oxide low silicon phosphate concentrate by adopting the silica-calcia low-grade collophanite positive and inverse floatation process, successfully achieves mineral processing enrichment of collophane calcium collophanite, and can improve use rate of phosphorus resource. The silica-calcia low-grade collophanite positive and inverse floatation process overcomes the defects that an existing floatation process can not be applied for mineral processing of silica-calcia collophanite which is high in content of high power half oxides.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

Repair agent for treating compound pollution of heavy metal in soil and preparation method of repair agent

InactiveCN106800939AIncrease surface areaReduce agglomerationAgriculture tools and machinesOther chemical processesSoil heavy metalsAgricultural residue

The invention discloses a repair agent for treating compound pollution of a heavy metal in soil and a preparation method of the repair agent. The repair agent is prepared from the following components in parts by weight: 6-8 parts of modified nano-carbon black, 2-5 parts of sodium bentonite-loaded nano zero-valent iron, 1-2 parts of phosphate mineral and 5-10 parts of decomposed forestry and agricultural residues. The preparation method comprises the steps of (1) crushing the phosphate mineral and the decomposed forestry and agricultural residues into powder of which the particle size is 100-200 meshes separately and drying for later use; and (2) mixing the modified nano-carbon black, the phosphate mineral, the sodium bentonite-loaded nano zero-valent iron and the decomposed forestry and agricultural residues according to the formula, and stirring in a closed container to prepare the repair agent for treating compound pollution of the heavy metal in the soil.

Owner:四川省有色冶金研究院有限公司

Process for making organic/inorganic composites

The subject invention concerns a composite comprising an organic fluid-swellable matrix, such as collagen, and mineral phase, such as calcium carbonate or phosphate mineral phase, for use as a biomimetic of bone. In another aspect, the subject invention concerns a process for making a composite involving the inclusion of acidic polymers to a supersaturated mineralizing solution, in order to induce an amorphous liquid-phase precursor to the inorganic mineral, which is then absorbed (pulled by capillary action) into the interstices of the organic matrix, and subsequently mineralizes via solidification and crystallization of the precursor phase. The present invention further concerns a method of treating a patient suffering from a bone defect by applying a biomimetic composite to the bone defect site.

Owner:FLORIDA UNIV OF A FLORIDA +1

Biomimetic organic/inorganic composites, processes for their production, and methods of use

The subject invention concerns a composite comprising an organic fluid-swellable, fibrous matrix, such as collagen, and a mineral phase, such as calcium carbonate or phosphate mineral phase, for use as a biomimetic of bone. In another aspect, the subject invention concerns a process for making a composite involving the inclusion of acidic polymers to a supersaturated mineralizing solution, in order to induce an amorphous liquid-phase precursor to the inorganic mineral, which is then absorbed (pulled by capillary action) into the organic matrix. Advantageously, once solidified, a high mineral content can be achieved, with the inorganic mineral crystals embedded within the collagen fibers (intrafibrillarly) and oriented such that they are aligned along the long axes of the fibers of the organic matrix, thereby closely mimicking the natural structure of bone. The present invention further concerns a method of treating a patient suffering from a bone defect by applying a biomimetic composite to the bone defect site.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

Phosphate mineral inhibitor, its application in reverse floatation of phosphorus ore and preparation method

The present invention relates to a phosphate mineral depressing agent, its application in back-flotation of phosphorus ore and its preparation method, in which the phosphate mineral depressing agent is a derivative of phosphoric acid, pyrophosphoric acid or tetraphosphoric acid. The back-flotation operation for removing carbonate mineral from raw ore containing phosphate mineral or intermediate product uses the derivative of phosphoric acid as depressing agent of phosphate mineral. The preparation method of the phosphoric acid derivative includes the following steps: in wet phosphoric acid, adding phosphorus pentoxide, its added quantity is 200-400% of wet phosphoric acid quantity, heating and stirring so as to obtain the invented phosphoric acid derivative.

Owner:WUHAN CHEM COLLEGE

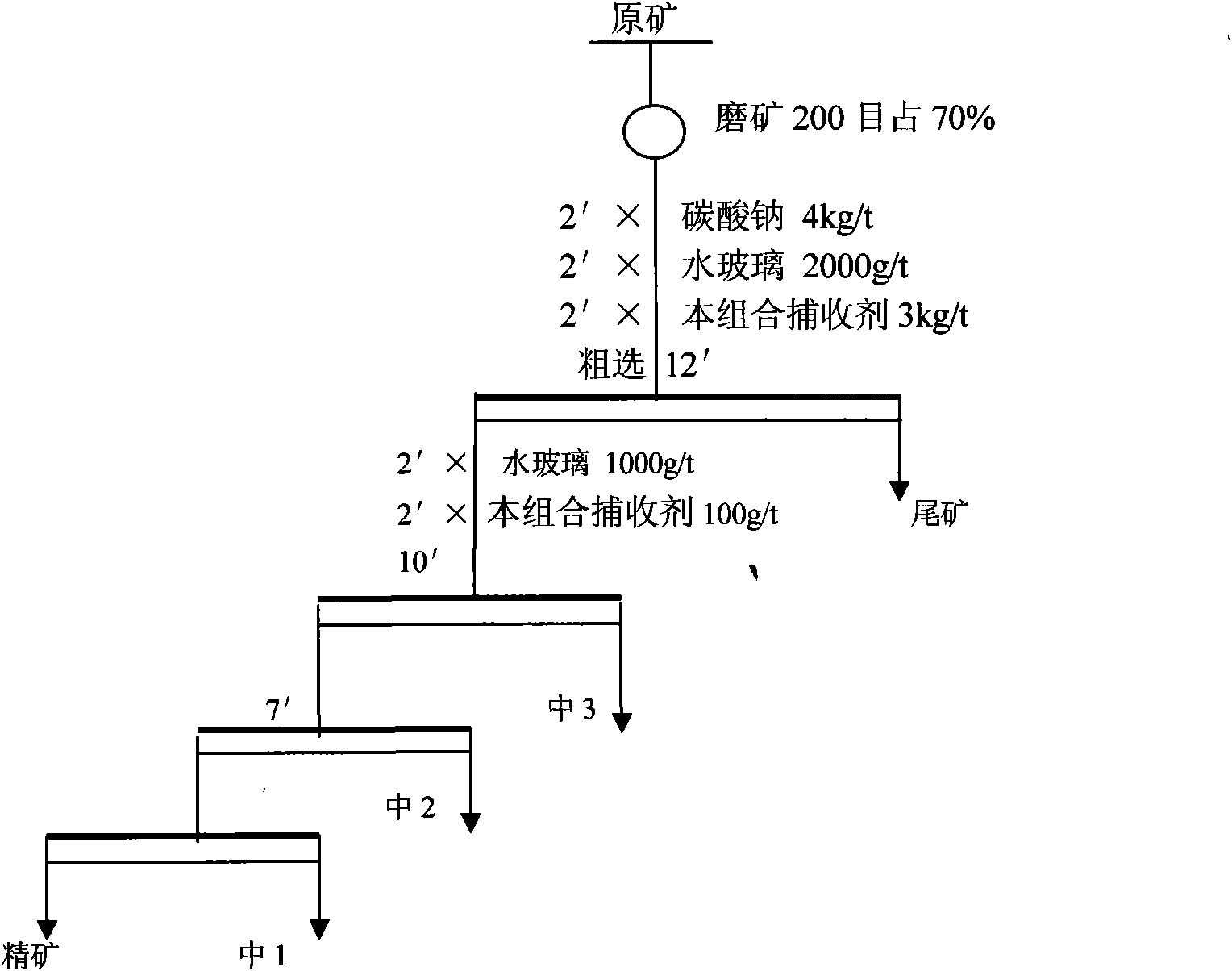

Combined collector of phosphorite

The invention discloses a combined collector of phosphorite. The invention relates to a floatation agent suitable for phosphate mineral with large mud content and belongs to the technical field of mineral machining engineering. The combined collector adopts another two agents which are combined and used in a conventional oxidized paraffin soap collector; the mixture ratio of the combined collector comprises that: the ratio of oxidized paraffin soap to salt to sodium oleate is 2:0.1:1; and three agents synergize to have more obvious and better effect than independently using the oxidized paraffin soap and the sodium oleate. The combined collector is used, can substantially reduce the consumption of sodium carbonate, and is favorable for sedimentation of concentrated ore; and the combined collector has wide source of raw materials, moderate price and market popularization value.

Owner:KUNMING UNIV OF SCI & TECH

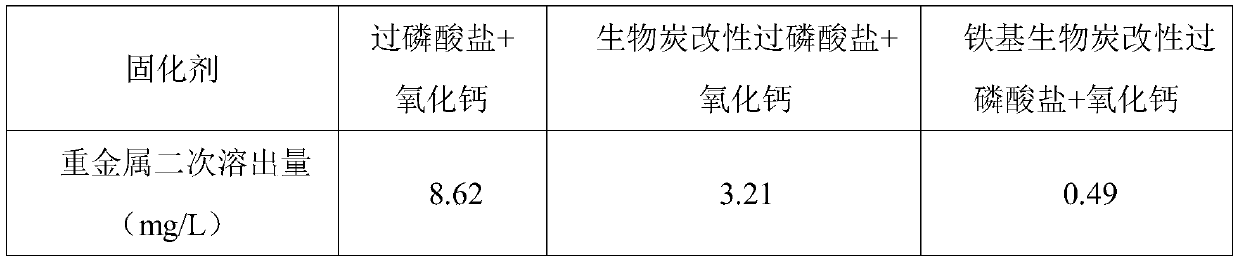

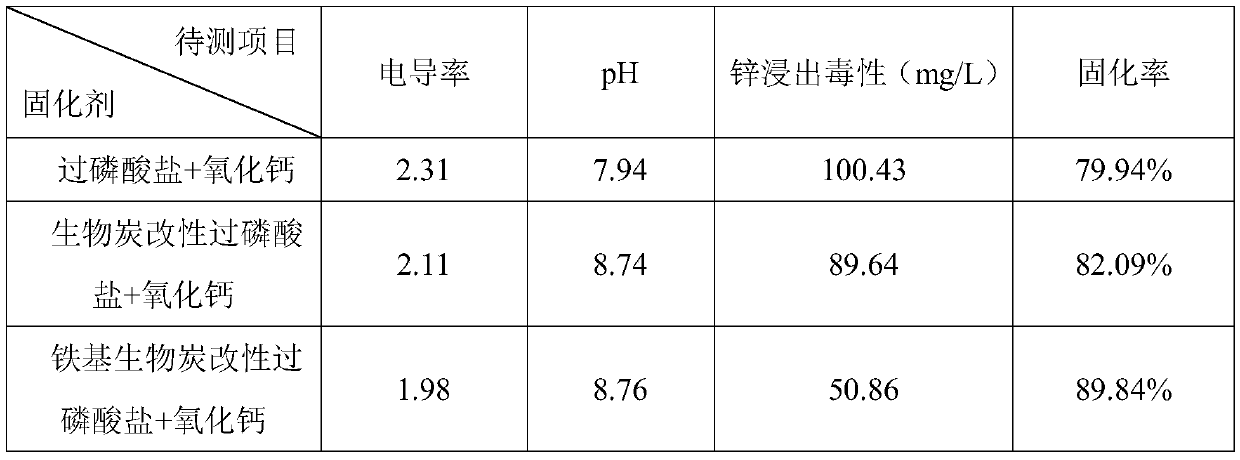

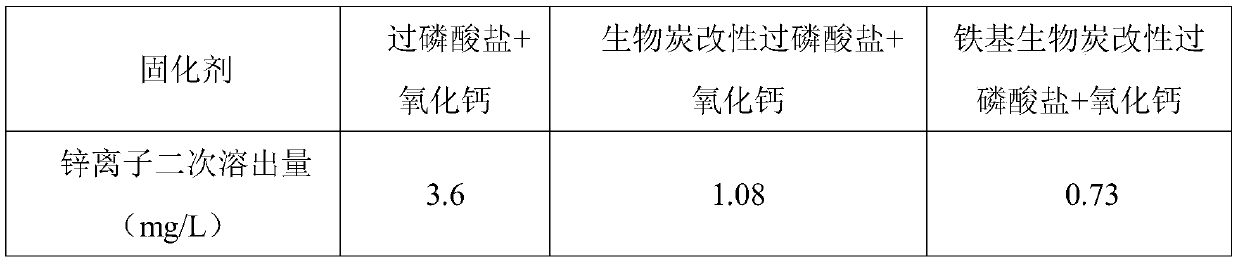

Heavy metal polluted soil solidification and repairing composite compound and solidification and repairing method

ActiveCN110699084AInhibit oxidative decompositionReduced risk of secondary dissolutionOther chemical processesContaminated soil reclamationIron saltsSoil heavy metals

The invention discloses a heavy metal polluted soil solidification and repairing composite compound and a solidification and repairing method. The composite compound comprises the following componentsin percentage by mass: 20-40% of quicklime and 60-80% of an iron-based biochar modified phosphate mineral, wherein the iron-based biochar modified phosphate mineral is obtained by uniformly mixing and drying an iron salt and biomass, further mixing the mixture with a phosphate mineral uniformly and performing co-pyrolysis. The method for solidifying and repairing heavy metal polluted oil by usingthe composite compound comprises the following steps: firstly, uniformly mixing the iron-based biochar modified phosphorate mineral with quicklime so as to obtain the heavy metal polluted soil solidification and repairing composite compound; applying the composite compound into heavy metal polluted soil, adding water, and performing uniform stirring; and performing maintenance of the best standards, so as to complete solidification repairing on the heavy metal polluted soil. By adopting the heavy metal polluted soil solidification and repairing composite compound, secondary dissolution of heavy metals can be greatly avoided, and the long-term stability of solidification of the heavy metal polluted soil can be greatly enhanced.

Owner:SOUTHEAST UNIV

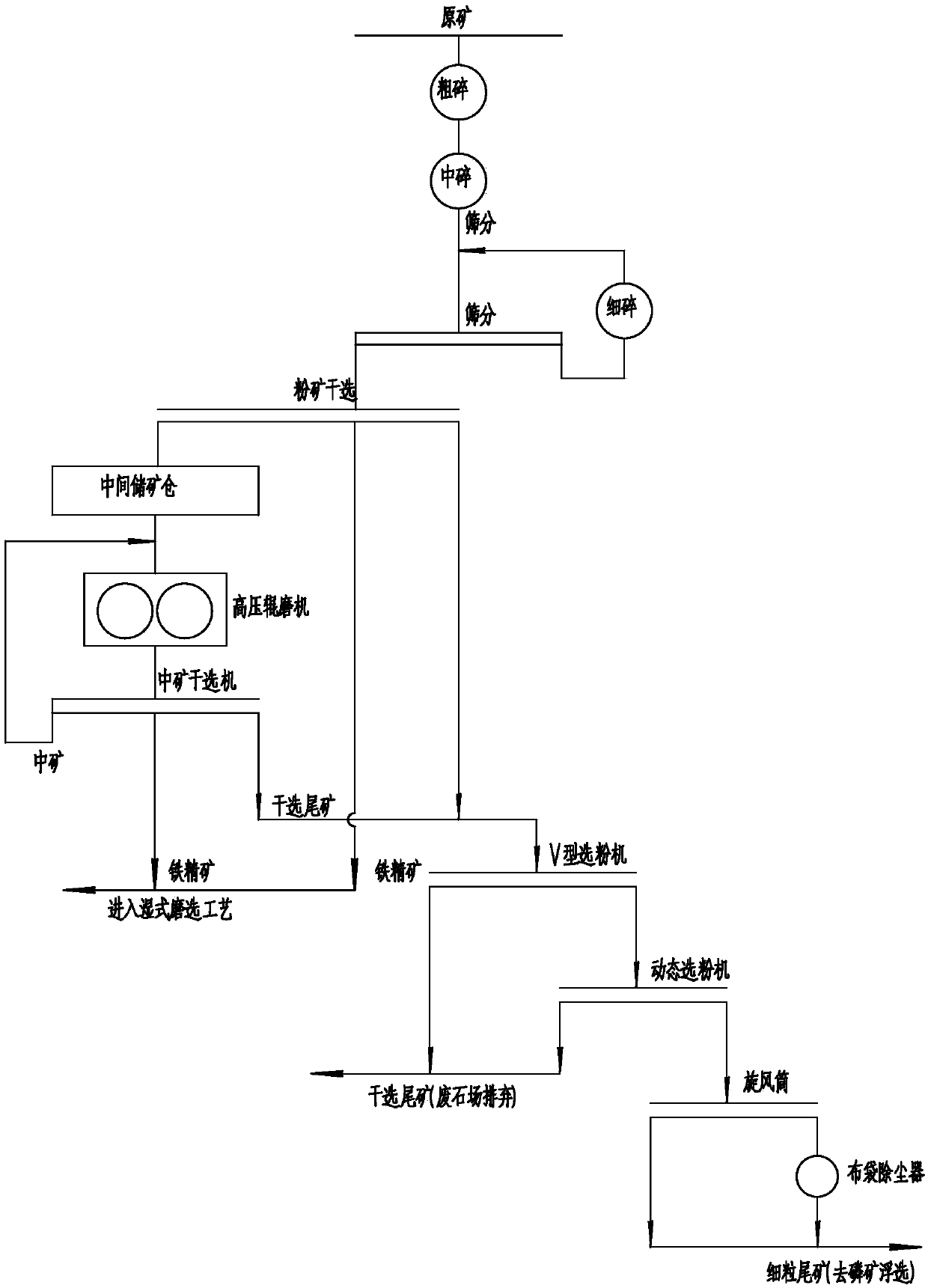

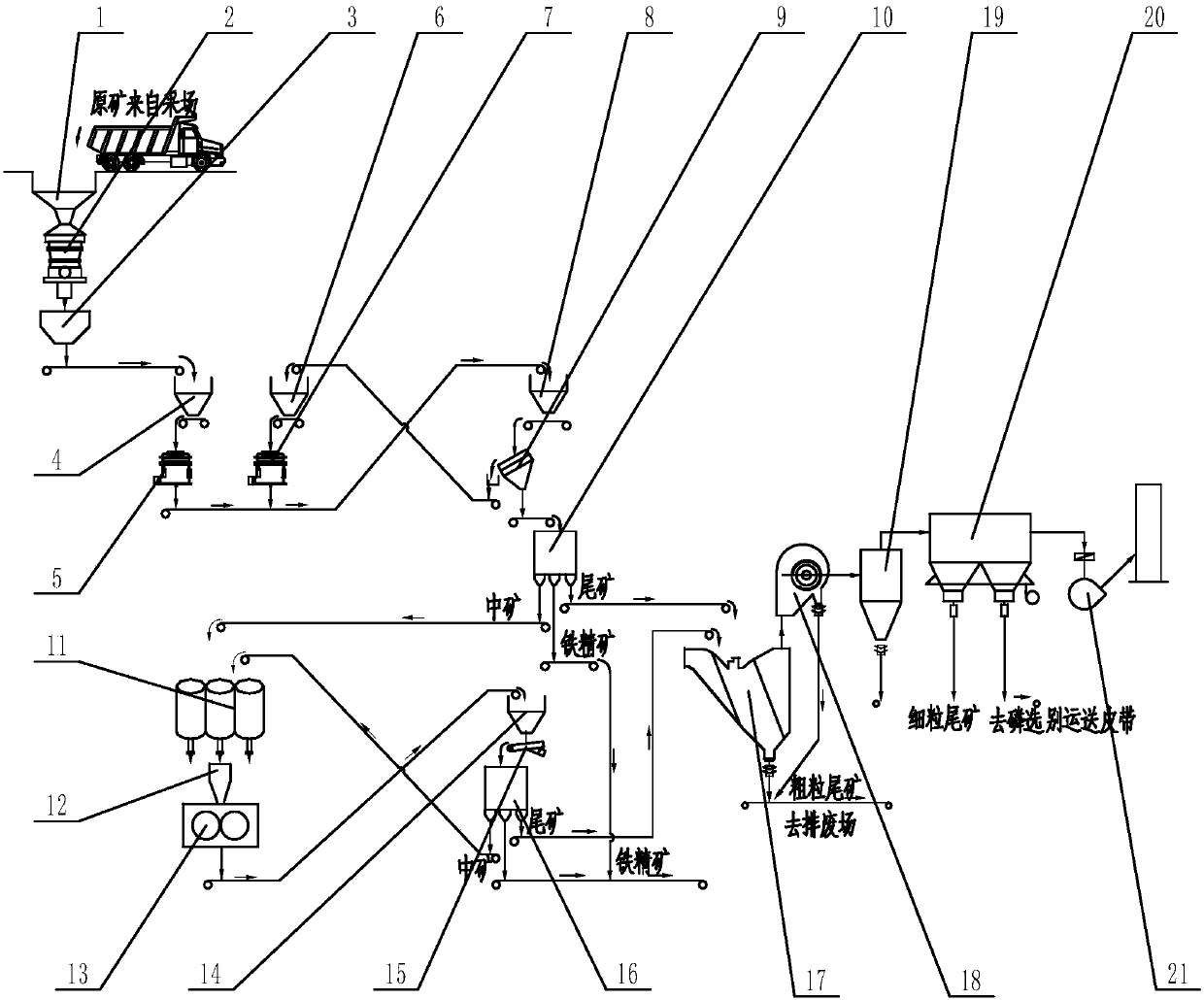

Extremely low content magnetite beneficiation method and system for associated phosphate minerals

The invention relates to the technical field of beneficiation, in particular to an extremely low content magnetite beneficiation method and system for associated phosphate minerals. The method provided by the invention comprises the step of carrying out multi-stage sorting, namely finely grinding raw ore, carrying out dry separation on ore fines, carrying out superfine crushing by adopting a high-pressure grinding roller, then carrying out dry separation on middlings, and carrying out dry separation by adopting a V-shaped powder selecting machine and a dynamic powder selecting machine, so thatiron core concentrate and tailings are separated, the next wet type grinding and separation treatment capacity is reduced, grinding and separation energy consumption is reduced, water resource is saved, wetting tailing amount is reduced, and beneficiation cost is effectively reduced.

Owner:中冶沈勘工程技术有限公司

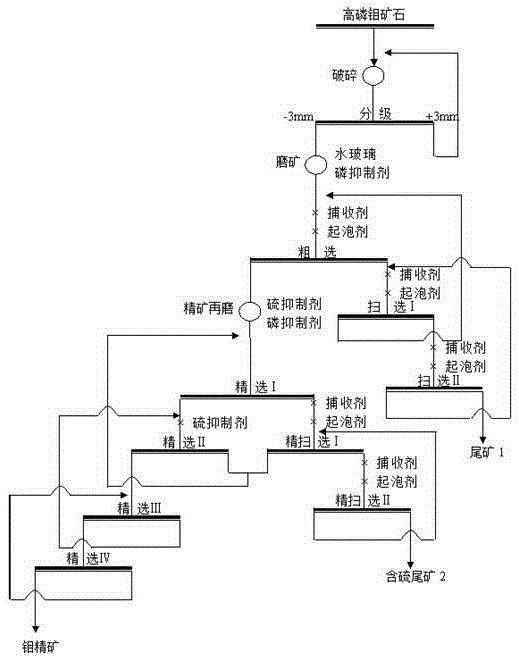

Physical concentration and phosphorus reduction method for skarn-type high-phosphorus molybdenum ore

The invention discloses a physical concentration and phosphorus reduction method for a skarn-type high-phosphorus molybdenum ore. The physical concentration and phosphorus reduction method comprises the following steps of (1) crushing, namely crushing raw ores by using a crusher, sieving, and returning a +3mm-grade raw ore to crush until the particle size of the raw ore is up to the -3mm grade; (2) grinding the ores, namely adding the crushed -3mm-grade raw ore into raw ore grinding equipment to carry out closed-circuit ore grinding operation, meanwhile, adding 500-1000g / t of water glass and 250-800g / t of a phosphate mineral inhibitor into a grinding machine, and grinding the raw ore until the particle size is up to the -0.075mm grade and the phosphorus content is up to 55-75%; (3) carrying out roughing operation; (4) carrying out scavenging operation; (5) regrinding a roughed molybdenum concentrate, namely adding 100-280g / t of a sulfur inhibitor and 150-300g / t of a phosphate mineral inhibitor to regrind the roughed molybdenum concentrate in roughed molybdenum concentrate regrinding equipment until the particle size is up to the -0.045mm grade and the phosphorus content is up to 70-95%; and (6) carrying out fine flotation operation. By using the physical concentration and phosphorus reduction method, the phosphorus content of a molybdenum concentrate product can be reduced to be lower than the standard, and a high-quality molybdenum concentrate product can be obtained.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

Method for producing high-quality active ecological organic raw material from livestock and poultry manure

The invention discloses a method for producing a high-quality active ecological organic raw material from livestock and poultry manure. First, a Chinese herbal medicine is added to livestock and poultry feedstuffs; the feedstuffs with the Chinese herbal medicine are digested and absorbed by livestock and poultries, and an additive composed of an azotobacteria flora, potassium mineral powder and phosphate mineral powder is added to the obtained livestock and poultry manure; the mixture is well mixed by stirring, and is placed in a plastic basket; the plastic basket is sealed by using a plasticfilm, and anaerobic fermentation is carried out; the manure is stored for 25-45 days, odor and harmful gas in the manure are removed, roundworm eggs and pathogen are killed, crude protein in the livestock and poultry manure are decomposed into amino acid, and part of crude fiber and starch is decomposed into monosaccharide, such that the active ecological livestock-and-poultry-manure organic raw material used for producing a high-quality high-efficiency organic fertilizer is obtained.

Owner:贵州盛洋生物技术有限公司

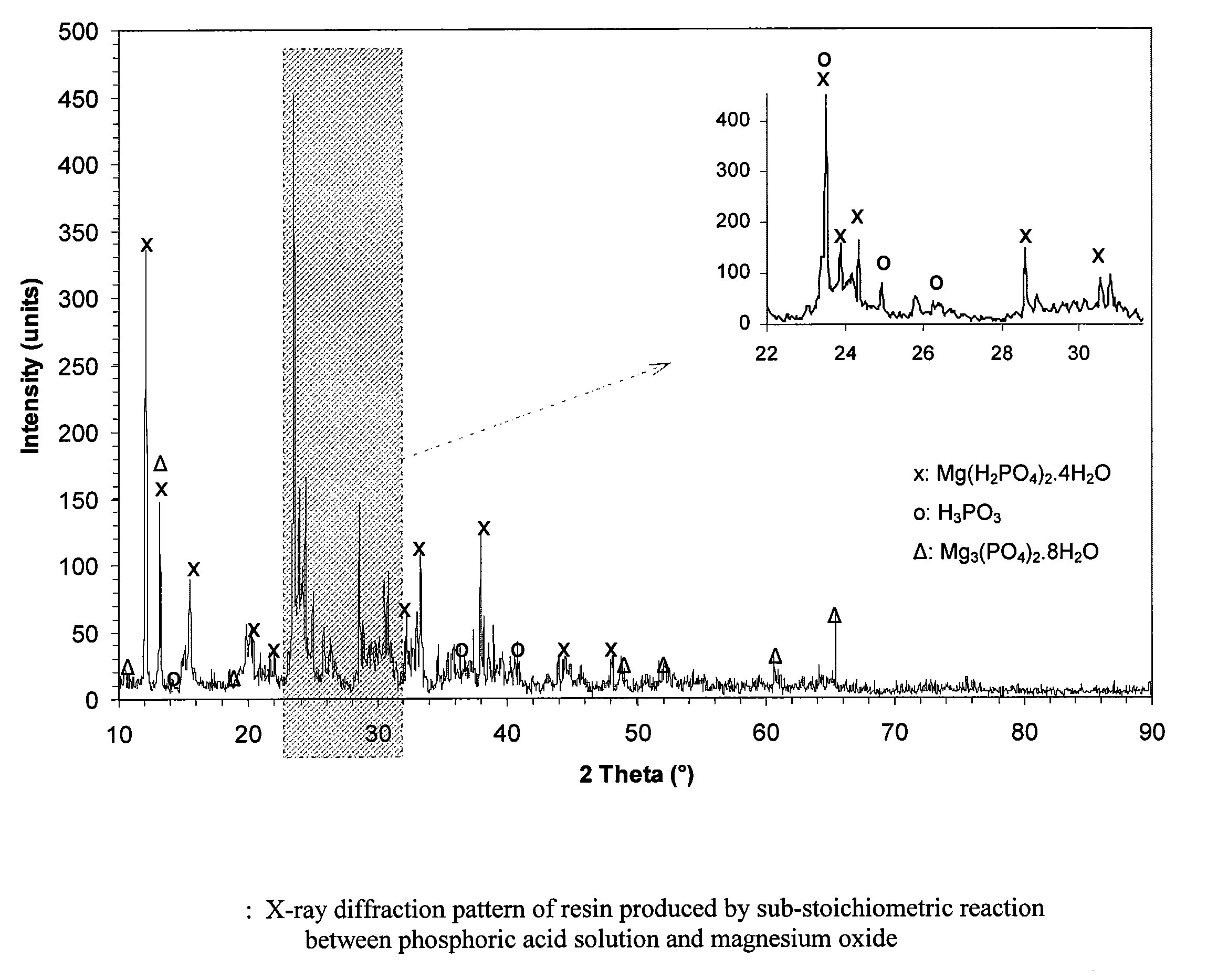

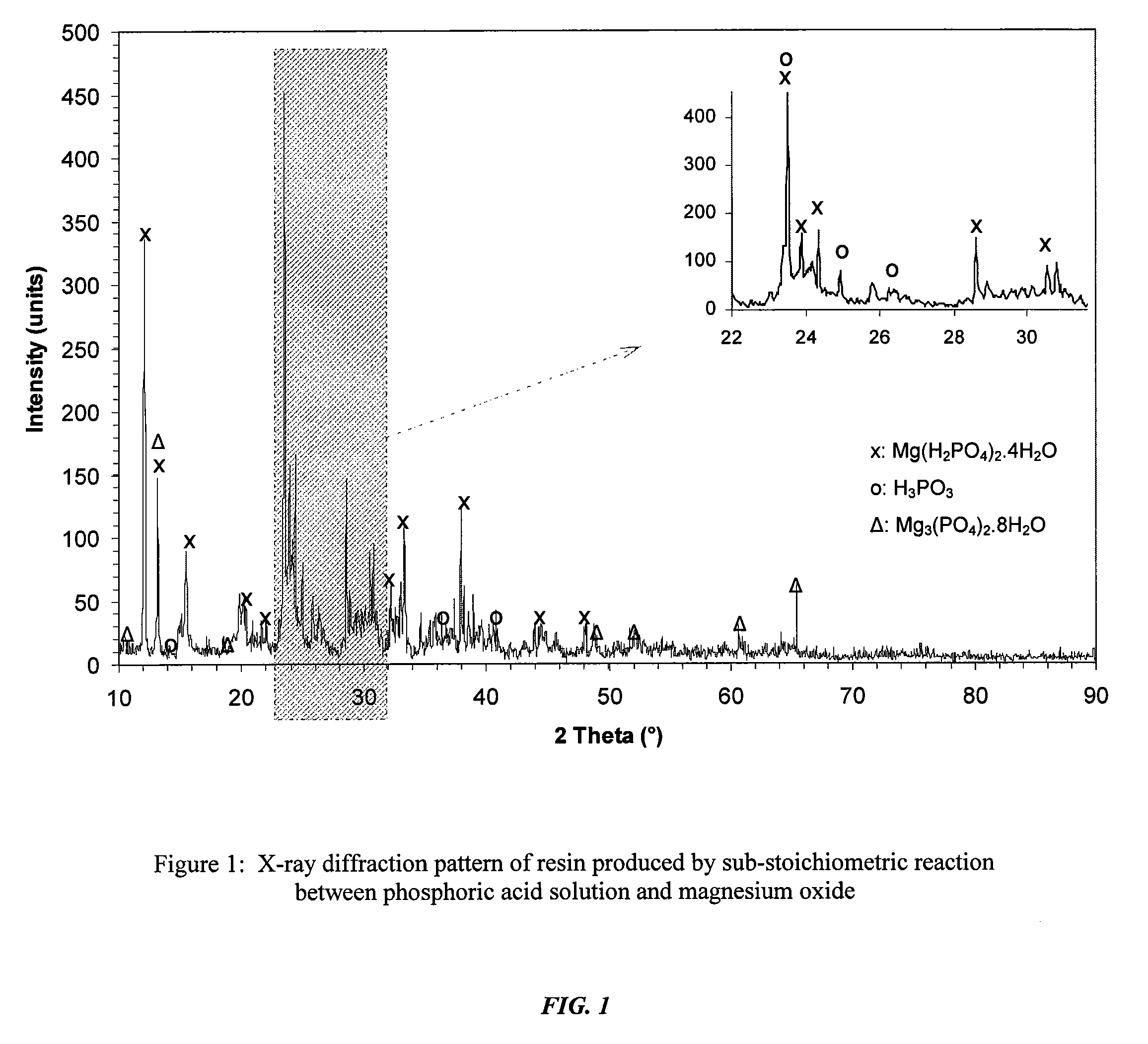

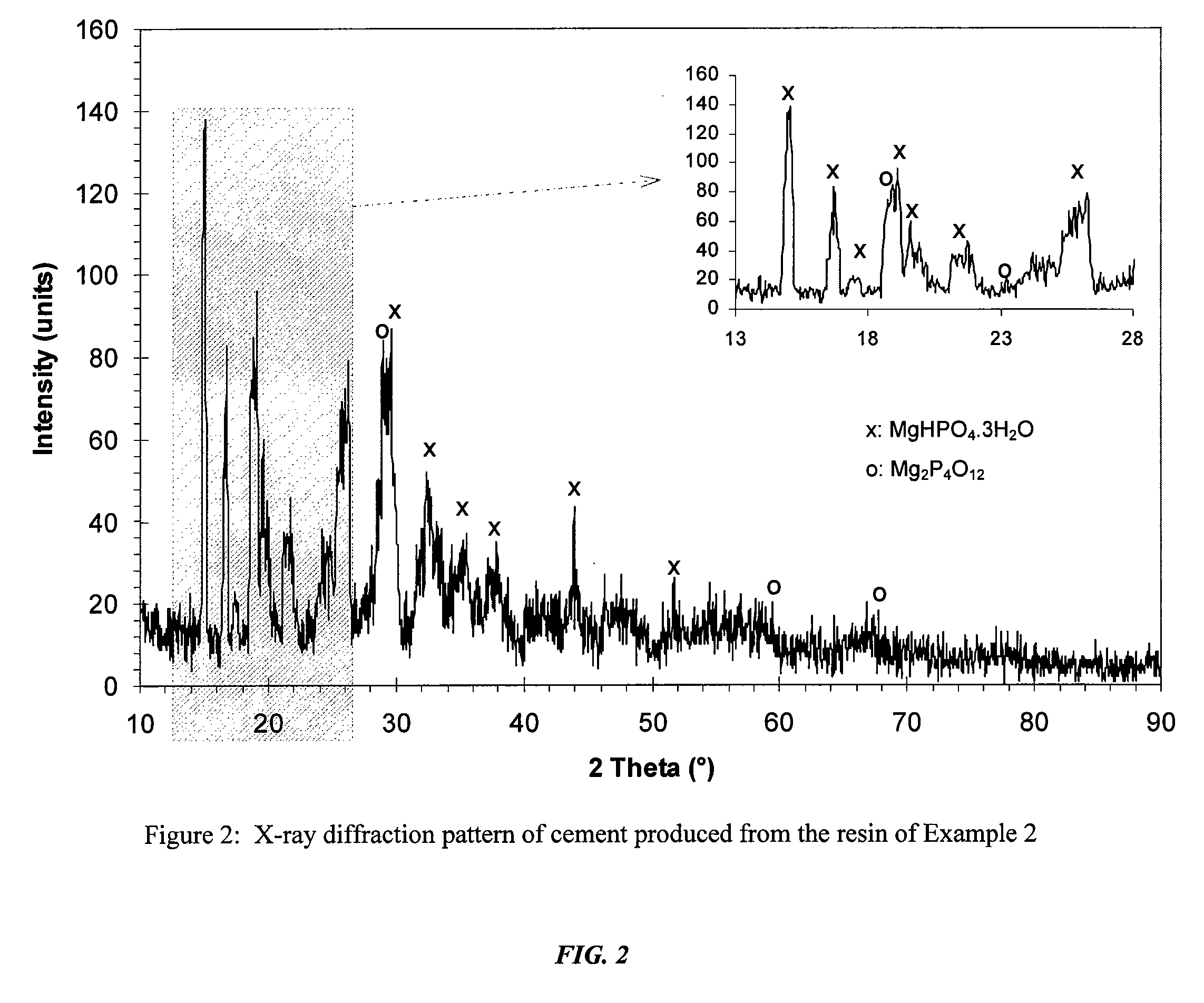

Inorganic Phosphate Resins and Method for Their Manufacture

ActiveUS20090312170A1Transportation safetyLow costPhosphorus oxidesPhosphatesOrganic synthesisFlexural strength

A method is provided for making inexpensive synthetic inorganic resins that are stable, mix easily with water and may be conveniently diluted to form an easy-to-use paste for commercial applications. The method uses environmentally friendly techniques to provide improved efficiencies in the commercial production of these resins. The resins are produced by the partial reaction of phosphoric acid with sparsely-soluble oxides, or sparsely-soluble oxide minerals, that are added to the phosphoric acid under controlled conditions. In certain specific embodiments, methods are provided for modifying synthetic inorganic resins so as to produce rapid-setting phosphate cements and ceramics having high flexural strength. Unique synthetic inorganic resin formulations are also disclosed. These formulations are phosphate-mineral based, non-volatile, tend to be non-flammable, do not contain any hazardous inorganic or organic compounds, and are chemically stable at relatively high temperatures, yet they are less expensive than most commercially available organic synthetic polymeric resins.

Owner:LATITUDE 18

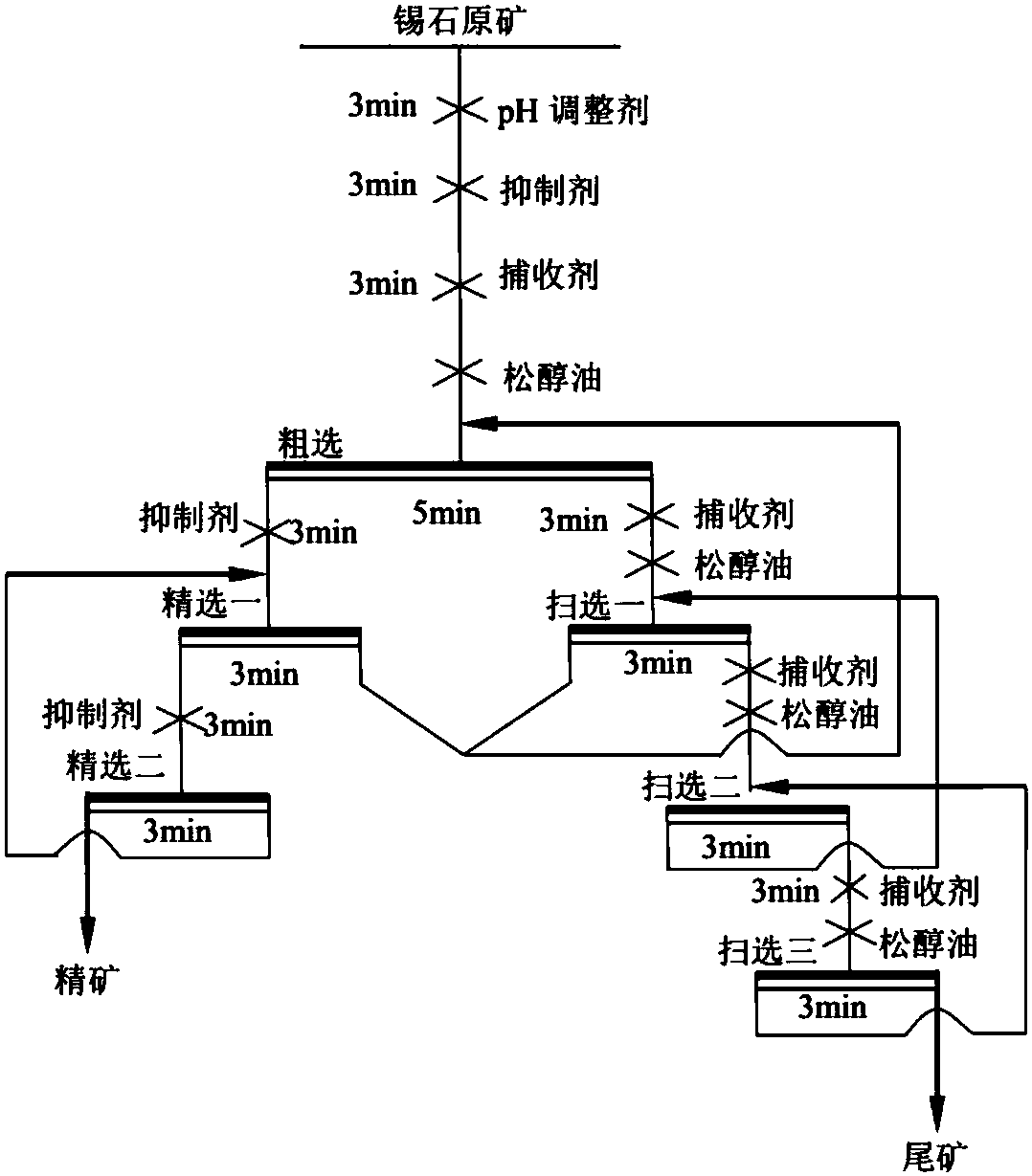

Manganese-magnesium low-grade phosphate flotation process

The invention discloses a manganese-magnesium low-grade phosphate flotation process. The process comprises the steps that firstly, manganese-magnesium low-grade phosphate ores are crushed and ground to enable manganese-magnesium minerals, phosphate minerals and other minerals to be subjected to monomer separation; secondly, a pH modifier is added into ore pulp to enable the pH value of the ore pulp to be greater than or equal to 11.6; and thirdly, an inhibitor and an obverse floatation collecting agent are added, and floatation is carried out after stirring and pulp conditioning. The adopted floatation process is a technological process including the rough concentration step, the concentration step and the scavenging step. Obtained ingroove products are flotation tailings. Obtained foam products are finished phosphate concentrate products with low MnO2 content, low MgO content and low SiO2 content, and the finished phosphate concentrate products are obtained finally through concentration, filtration and drying. According to the process, floatation is carried out directly under the alkali condition, dextrin and NO-2 are used in cooperation to reduce the content of silicate minerals, carbonate minerals and manganese minerals so as to obtain low-magnesium, low-manganese and low-silicon phosphate concentrates, so that mineral processing and enrichment of magnesium low-grade phosphate ores are realized successfully, and the utilization rate of phosphorus resources is increased.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +2

High-fertility and low-alkaline cementing material for vegetation concrete and preparation method thereof

InactiveCN109095849ALow costContribute to resource utilizationAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPlant rootsResource utilization

The invention relates to a high-fertility and low-alkaline cementing material for vegetation concrete and a preparation method thereof. The high-fertility and low-alkaline cementing material for vegetation concrete comprises phosphate minerals, re-fired magnesia, borax, limestone powder, active aluminum powder, silicate clinker and expanded perlite. Through the synergistic action of the components, the cost of the cementing material is greatly reduced while an excellent growth space is provided for plant roots, and the resource utilization of industrial waste is facilitated.

Owner:山东高速路用新材料技术有限公司

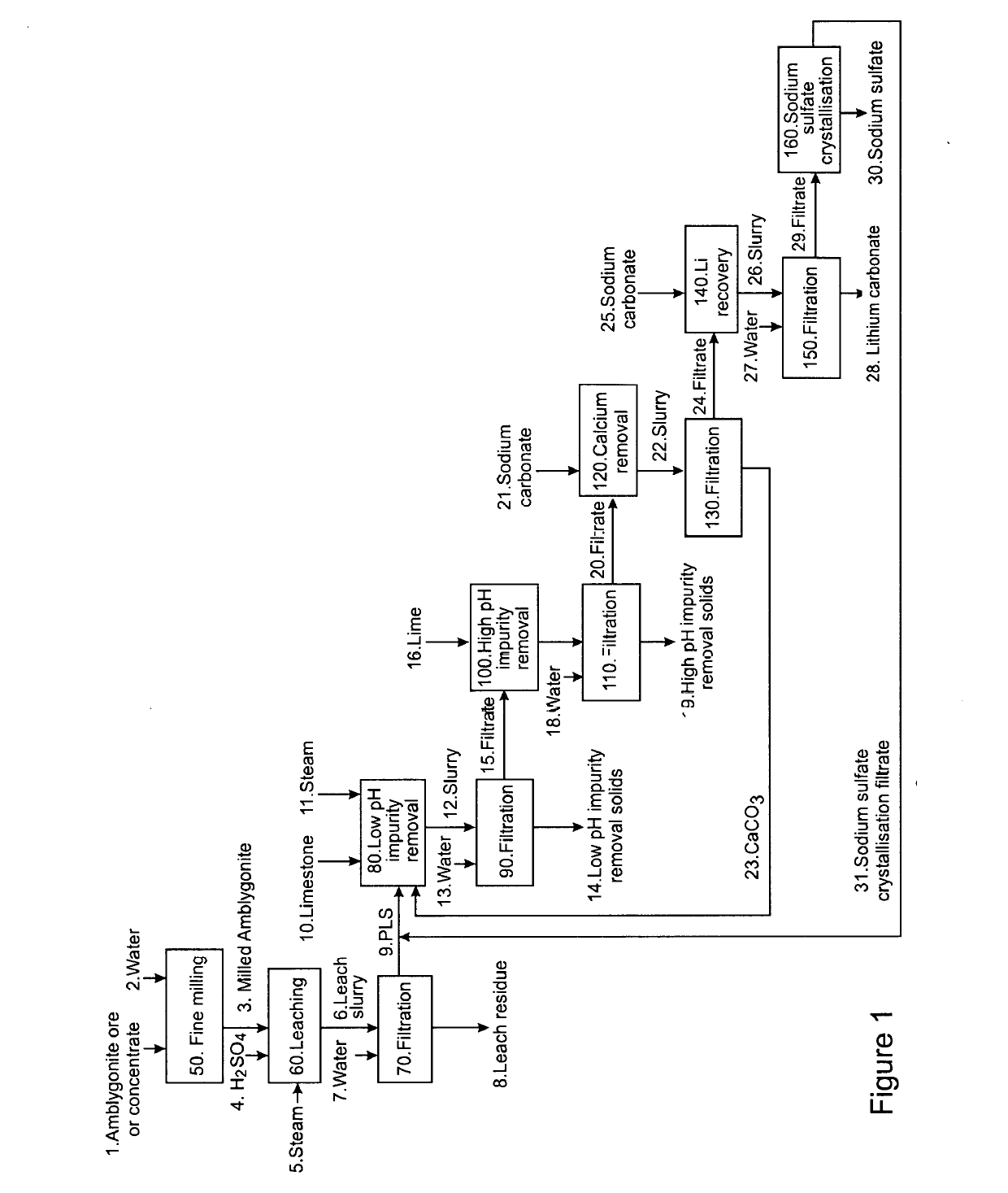

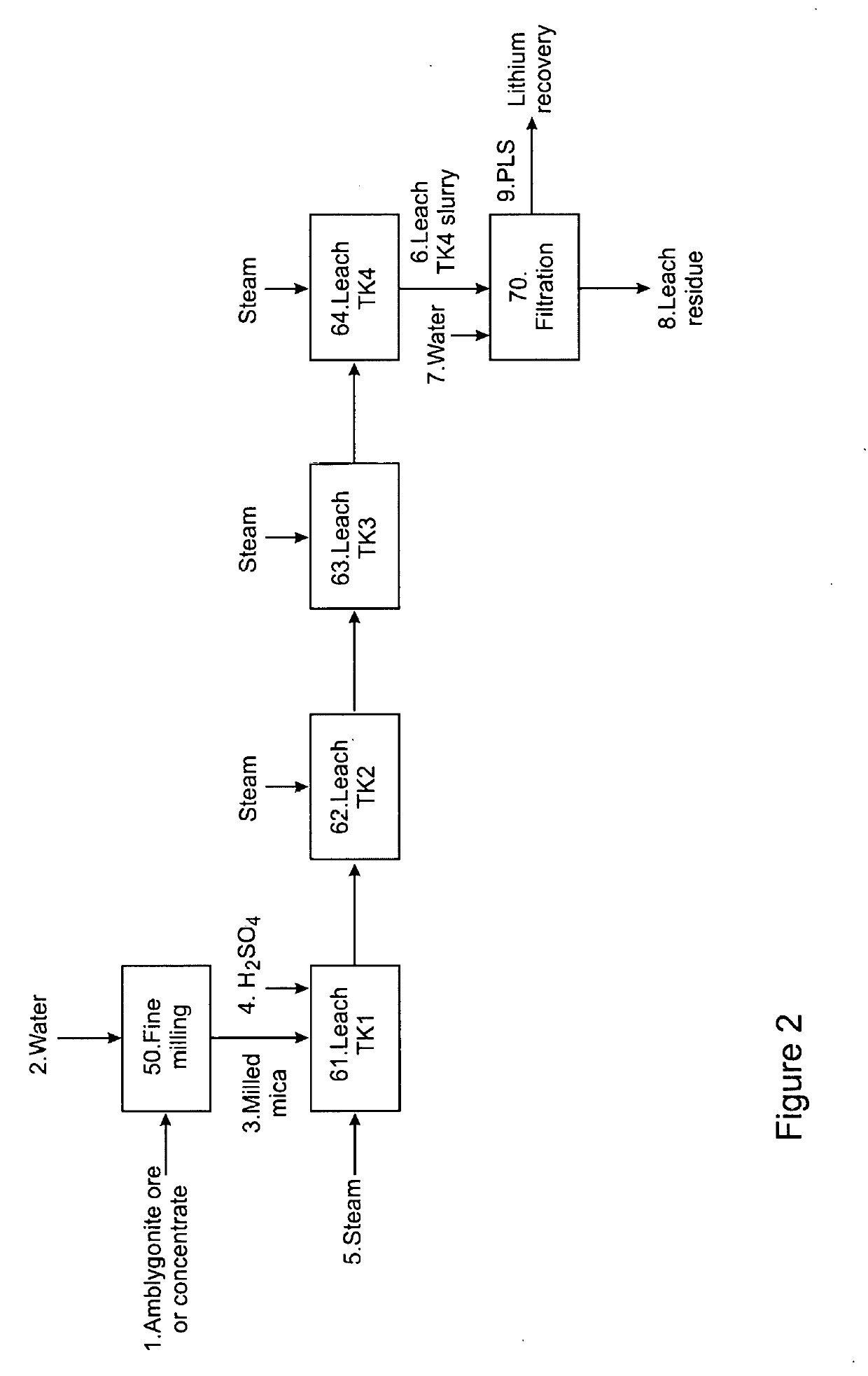

Lithium recovery from phosphate minerals

ActiveUS20190185963A1High recovery rate of lithiumLower the volumeProcess efficiency improvementLithiumPregnant leach solution

A process for the recovery of lithium from minerals rich in lithium and phosphate, the process comprising passing an ore containing one or more minerals rich in lithium and phosphate to an acid leach step thereby producing a pregnant leach solution, subjecting the pregnant leach solution to a series of process steps by which one or more impurity elements are removed, and recovering lithium as a lithium containing salt product, wherein the series of process steps by which one or more impurity elements are removed includes a low pH impurity removal step conducted at an elevated temperature for the precipitation of one or more impurities.

Owner:LI TECH PTY LTD

Beneficiation method for producing low-phosphorous molybdenum concentrate by utilizing ultrasonic waves

InactiveCN105413880AReduce manufacturing costImprove hydrophilicityFlotationMegasonic cleaningPhosphorite

The invention discloses a beneficiation method for producing low-phosphorous molybdenum concentrate by utilizing ultrasonic waves. The beneficiation method comprises the following steps: (1) carrying out ultrasonic treatment: carrying out ultrasonic dispersing and cleaning on medium-grade and high-grade high-phosphorous molybdenum concentrate obtained by flotation for 3-20 minutes at ultrasonic frequency of 28-80KHz and ultrasonic strength of 200-400W, simultaneously adding a phosphate mineral inhibitor with amount of 1500-7000g / t to carry out dispersion inhibition on phosphor-containing minerals; (2) carrying out primary flotation; (3) carrying out flotation scavenging; and (4) carrying out flotation concentration. According to the beneficiation method, by utilizing ultrasonic means and adding the efficient phosphor inhibitor, phosphor content in a molybdenum concentrate product generated by flotation is reduced to be below the standard, so that qualified low-phosphorous molybdenum concentrate is obtained. According to the method, a chemical phosphorus removal process of a beneficiation plant is cancelled, production cost and generation of waste liquor are reduced, and economic benefits and environmental benefits are remarkable.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

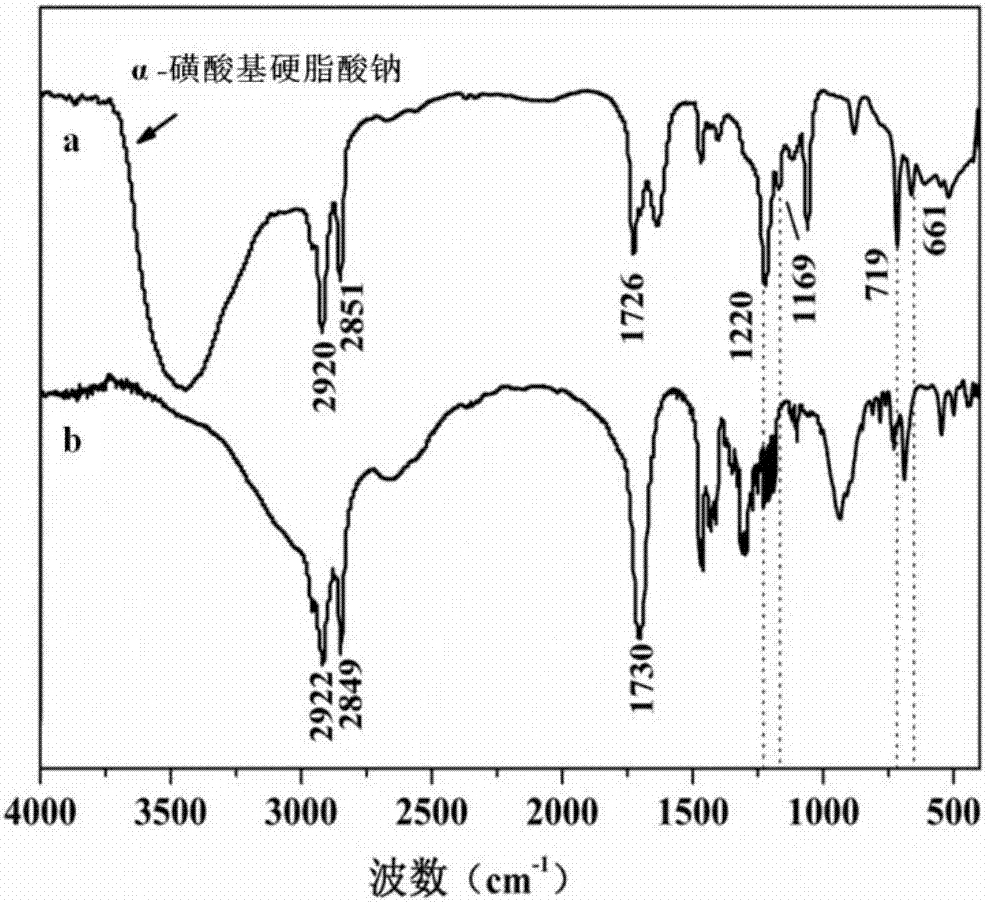

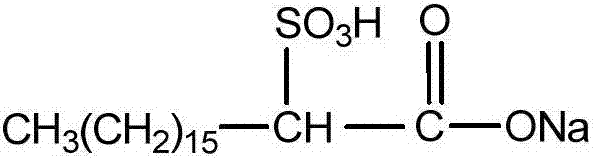

Calcium-magnesium collophane ore reverse flotation collector and preparation method thereof

InactiveCN107213991AImprove sorting effectEnhanced harvesting capacityFlotationSulfonic acid preparationChlorosulfuric acidPhosphorite

The invention relates to a calcium-magnesium collophane ore reverse flotation collector and a preparation method thereof. The calcium-magnesium collophane ore reverse flotation collector is prepared and obtained in the modes that saturated fatty acid serves as a reaction raw material, chlorosulfonic acid is selected as a sulfonating agent to conduct sulfonating reaction, and then a sulfonating product is subjected to bleaching and neutralization reaction. The calcium-magnesium collophane ore reverse flotation collector and the preparation method thereof have the following beneficial effects that (1) according to the collector, a sulfonic group with the extremely strong polarity is selected to serve as a polar group of the collector, so that separation performance of the collector over phosphate minerals and carbonate minerals is improved; the saturated fatty acid is selected as a non-polar group of the collector, so that collecting performance of the collector over carbonate minerals is improved; and the product raw material source is widespread, the price is low, and certain cost price superiority and wide industrialization superiority are achieved; and (2) the preparation process of the calcium-magnesium collophane ore reverse flotation collector is simple, easy to operate and low in production cost, industrialized production is easy to realize, meanwhile, no three-waste discharge exists in production, and environment friendliness and non-pollution are achieved.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

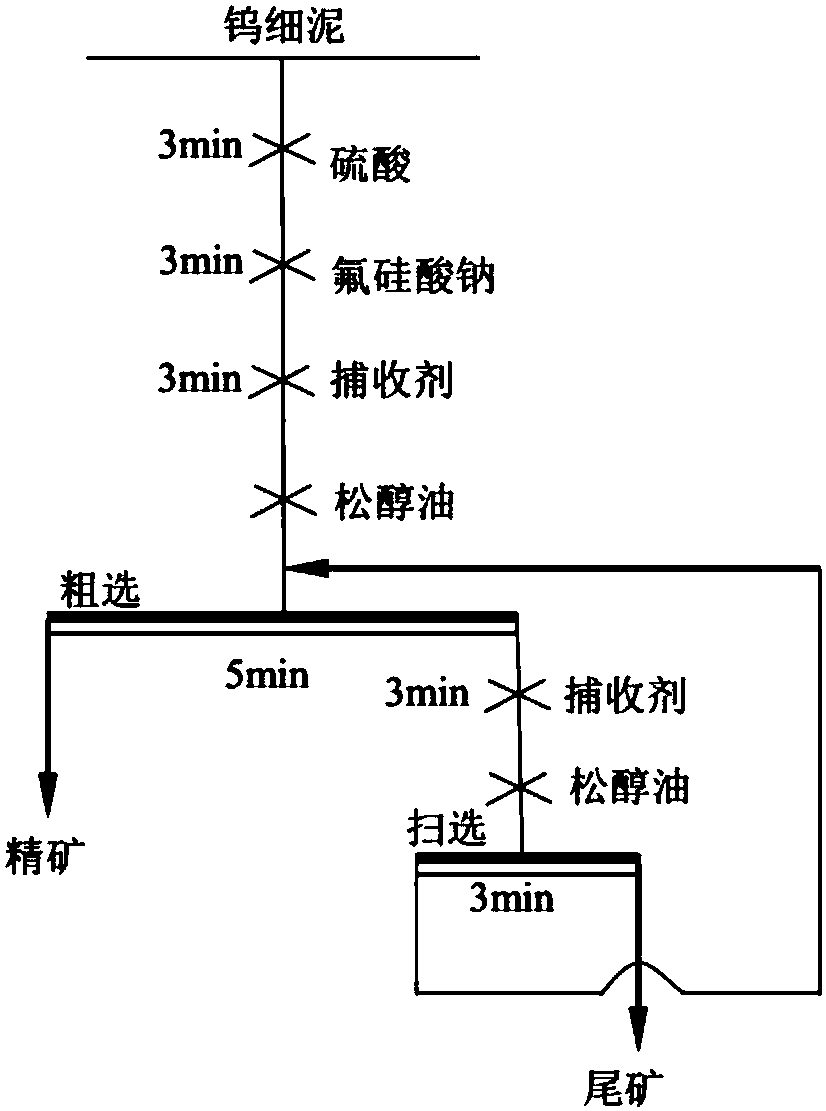

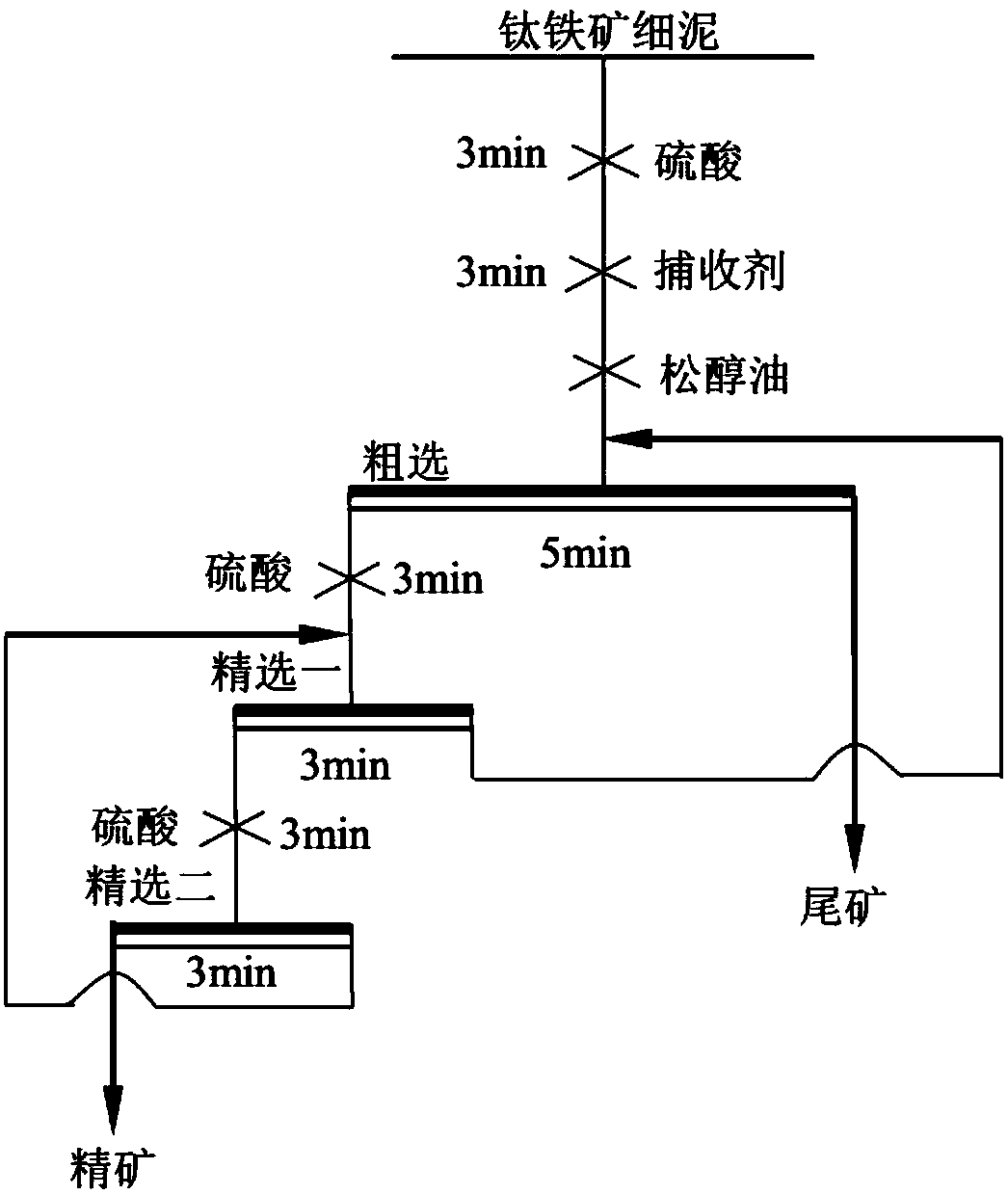

Non-sulfide mineral flotation collector and application thereof

The invention discloses a non-sulfide mineral flotation collector and application of the non-sulfide mineral flotation collector, and belongs to the technical field of mineral flotation collectors. The non-sulfide mineral flotation collector is prepared from carboxyl phenylphosphonic acid and salt thereof and has the advantages of being good in water solubility in normal temperature, easy to disperse, high in collection capability, good in selectivity and the like, and is mainly used for flotation and separation of valuable mineral in ilmenite, scheelite, wolframite, rutile, cassiterite, fluorite, rare earth ore, bauxite, manganese carbonate ore or phosphate minerals. The collector is low in cost, safe, environmentally friendly, high in flotation recycling rate and suitable for large-scaleindustrial application.

Owner:NORTHEASTERN UNIV

Special ground fertilizer-natural ore fertilizer for alkaline land

The invention provides a special base fertilizer-natural ore fertilizer for the saline alkali lands, and the special base fertilizer-natural ore fertilizer is a special fertilizer for improving the saline alkali lands. In recent years, the salinization degree of the soil keeps rising, and the area of saline alkali lands has being expanded and increased at an annual speed of 1.5 percent. The situation brings difficulties to the production and living of people as well as the regional economic development. The special base fertilizer-natural ore fertilizer for the saline alkali lands changes the soil character and activates the land capability factors. Aiming at the five major factors for the development of the saline alkali lands, potash feldspar ore, the phosphate ore, the silicate ore and the organic rock are adopted to produce the special base fertilizer-natural ore fertilizer for the saline alkali lands. The unique crystal structure in the ore changes the situation of saline alkali soil, and the ion exchange lowers the PH value of the soil. The molecule pore preserves water and prevents drought, thereby increasing the soil nutrient. 5 particles of the powder in A bag are fertilized 30 centimeters deep in soil by the 9SF-2.45 type rat channel steppe scarification fertilizer distributor, with 8 tons of fertilizer for each hectare; and the scrap in the B bag is ploughed under 10 to 15 centimeters deep underground by a tractor-propelled five-furrow plough, with 8 to 30 tons of fertilizer for each hectare.

Owner:商万有

Methods of increasing flotation rate

InactiveUS20050167340A1Improve hydrophobicityIncrease ratingsFlotationLipid formationHydrophobic polymer

Methods of increasing the rate of separating hydrophobic and hydrophilic particles by flotation have been developed. They are based on using appropriate reagents to enhance the hydrophobicity of the particles to be floated, so that they can be more readily collected by the air bubbles used in flotation. The hydrophobicity-enhancing reagents include low HLB surfactants, naturally occurring lipids, modified lipids, and hydrophobic polymers. These methods can greatly increase the rate of flotation for the particles that are usually difficult to float, such as ultrafine particles, coarse particles, middlings, and the particles that do not readily float in the water containing large amounts of ions derived from the particles. In addition, new collectos for the flotation of phosphate minerals are disclosed.

Owner:YOON ROE HOAN

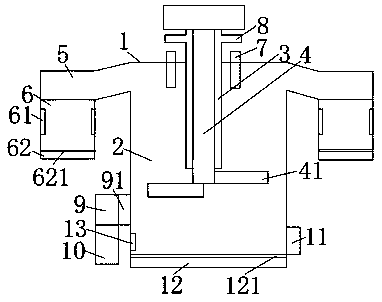

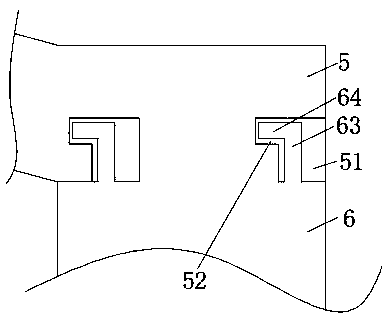

Flotation separation device for industrial production of composite phosphate minerals

The invention discloses a flotation separation device for industrial production of composite phosphate minerals, and relates to the technical field of floatation separation. The flotation separation device comprises a flotation separation device body, wherein the flotation separation device body comprises a flotation tank, a hollow column, a main shaft, a flotation tube and a concentrate collection box, the middle of the upper end of the flotation tank is fixedly connected with the upper end of the hollow column, scraping plates are fixedly arranged at the upper end of the flotation tank, thenumber of the scraping plates is two, the two scraping plates are located on the two sides of the hollow column correspondingly. According to the flotation separation device for the industrial production of the composite phosphate minerals, on one hand, the flotation tube can enable the floated ore foam to automatically flow into the concentrate collection box, on the other hand, a spray head in the concentrate collection box can carry out primary cleaning on the incoming concentrate so as to facilitate the next process, secondary, the ore foam which does not flow into the flotation tube afterthe floatation separation device stops operating can be scraped into the flotation tube through the scraping plates, and in addition, an air blowing machine can blow the ore which is not stirred at the bottom to enable the ore to be stirred.

Owner:SUQIAN MODERN CHEM

Composite heavy metal polluted soil in-situ fixing method

ActiveCN102303041BPromote mineralization reactionQuick fixContaminated soil reclamationSodium BentoniteWater insoluble

The invention discloses a composite heavy metal polluted soil in-situ fixing method. The method comprises the following steps of: preparing a heavy metal polluted soil restoration agent by using 80 to 90 weight parts of bentonite or kaolin serving as a filling agent, 0.5 to 15 weight parts of ferrous sulfide, 0.5 to 5 weight parts of magnesium sulfate, 1.5 to 8 weight parts of magnesium sulfite, 1 to 5 weight parts of magnesium oxide, 2 to 10 weight parts of calcium hydroxide and 1 to 5 weight parts of phosphorus-containing preparation; and mixing the components and heavy metal polluted soil according to the weight ratio of 1:(5-20), and uniformly stirring to make the humidity of the soil kept between 15 and 30 percent, wherein heavy metal ions in the polluted soil are converted into water-insoluble metal sulfides, hydroxides, multi-metal co-precipitates, basic carbonates and phosphate minerals, the biological activity of heavy metal is lost, and the heavy metal is fixed in the soil. The restored soil meets the requirement of second-level standard values of 'Environmental Quality Standard for Soil' (GB 15618-1995) in China.

Owner:刘阳生

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com