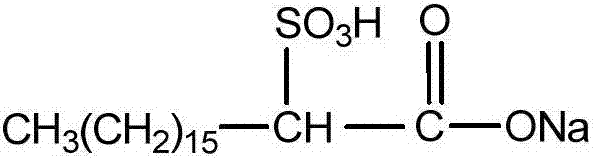

Calcium-magnesium collophane ore reverse flotation collector and preparation method thereof

A technology of collophosite and reverse flotation, which is applied in flotation, sulfonic acid preparation, solid separation, etc. It can solve problems such as difficult separation, achieve good separation performance, simple preparation process, and wide-ranging sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

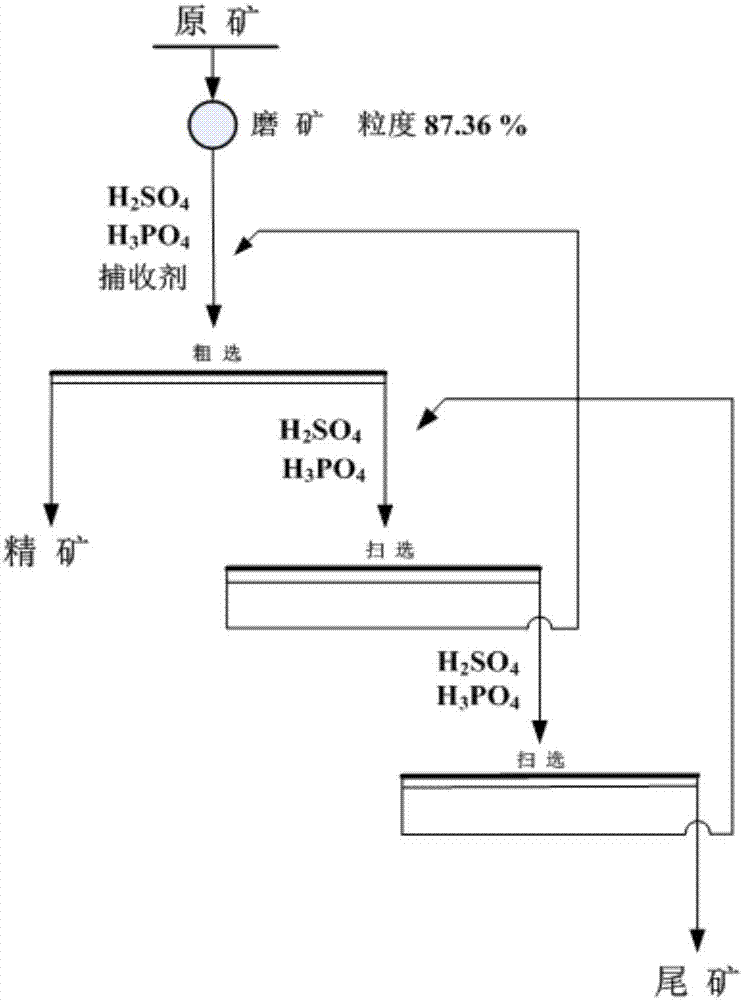

[0026] Such as figure 1 , the reverse flotation collector of calcium-magnesium collophosphine is prepared according to the following steps:

[0027] (1) 18.08g of stearic acid is placed in a four-necked flask equipped with a reflux condenser, a stirrer, a thermometer and a constant pressure dropping funnel, and the temperature is adjusted to be 60°C. After the stearic acid is completely melted, stir evenly, gradually Add chlorosulfonic acid dropwise, the rate of chlorosulfonic acid addition is 1 second / drop, and the ratio of the amount of stearic acid to chlorosulfonic acid is 1.0:1.2. After the chlorosulfonic acid is added dropwise, the temperature is raised to 90 within 0.5h. ℃, sulfonation reaction for 6h, then aging at 90°C for 1h, and cooling down to 60°C.

[0028] (2) Add hydrogen peroxide with 5% stearic acid mass into the sulfonated product solution, and reflux and bleach at a constant temperature of 60° C. for 1 hour. The obtained bleached product is a viscous light ...

Embodiment 2

[0032] The collector is prepared as follows:

[0033] (1) 18.08g of stearic acid is placed in a four-necked flask equipped with a reflux condenser, a stirrer, a thermometer and a constant pressure dropping funnel, and the temperature is adjusted to be 65°C. After the stearic acid is completely melted, stir evenly, gradually Add chlorosulfonic acid dropwise, the rate of chlorosulfonic acid addition is 1 second / drop, and the ratio of the amount of stearic acid to chlorosulfonic acid is 1.0:1.8. After the chlorosulfonic acid is added dropwise, the temperature is raised to 90 within 0.5h. ℃, sulfonation reaction for 2 hours, then aged at 90 ℃ for 2 hours, and cooled to 60 ℃.

[0034] (2) Add hydrogen peroxide with 3% stearic acid mass into the sulfonated product solution, reflux and bleach at a constant temperature of 60° C. for 1 hour, and the obtained bleached product is a viscous light yellow liquid.

[0035] (3) Then add water-acetone mixture to the sulfonation product soluti...

Embodiment 3

[0038] The collector is prepared as follows:

[0039] (1) Put 16.31g of palmitic acid in a four-necked flask equipped with a reflux condenser, a stirrer, a thermometer and a constant pressure dropping funnel, and adjust the temperature to 60°C. After the stearic acid is completely melted, stir evenly and dropwise Add chlorosulfonic acid, the rate of chlorosulfonic acid addition is 3 seconds / drop, the ratio of the amount of palmitic acid to chlorosulfonic acid is 1.0:1.4, after the addition of chlorosulfonic acid is completed, the temperature is raised to 90°C within 0.5h, The sulfonation reaction was carried out for 3 hours, followed by aging at a constant temperature of 90°C for 1 hour, and the temperature was lowered to 60°C.

[0040] (2) Add hydrogen peroxide with 5% palmitic acid mass to the sulfonated product solution, and reflux and bleach at a constant temperature of 55° C. for 2 hours. The obtained bleached product is a viscous light yellow liquid.

[0041] (3) Then a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com