Beneficiation method for producing low-phosphorous molybdenum concentrate by utilizing ultrasonic waves

A mineral processing method, ultrasonic technology, applied in flotation, solid separation, etc., can solve the problems of soluble metal mineral dissolution, high cost, and agglomeration of molybdenum sulfide mineral oil, achieving significant economic and environmental benefits, low production costs, and increased Hydrophilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

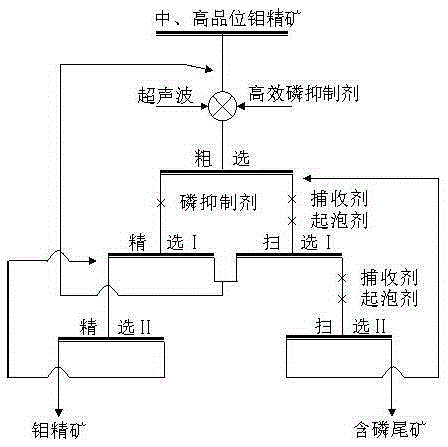

[0033] With Mo content being 41.87%, the unqualified molybdenum concentrate of P content 0.11% is raw material, utilizes technology of the present invention, carries out following steps, as figure 1 :

[0034] (1) Ultrasonic treatment: The high-phosphorus molybdenum concentrate is subjected to ultrasonic dispersion cleaning treatment in an ultrasonic cleaning machine, the ultrasonic frequency is 40KHz, the ultrasonic intensity is 350W, and the processing time is 10 minutes. At the same time, the binary copolymer of low molecular weight acrylic acid and maleic anhydride is added to inhibit the dispersion of phosphorus-containing minerals, and the dosage is 4000g / t.

[0035] (2) Rough selection by flotation: the processed molybdenum concentrate is used as raw material, and then put into the flotation machine for rough separation operation to obtain rough separation concentrate and rough separation tailings, which are used as raw materials for further selection , roughing tailin...

Embodiment 2

[0039] With Mo content being 45.27%, P content 0.065% phosphorus-containing molybdenum concentrate exceeding the standard as raw material, utilizing the process technology of the present invention, carry out following steps, as figure 1 :

[0040] (1) Ultrasonic treatment: The high-phosphorus molybdenum concentrate is subjected to ultrasonic dispersion cleaning treatment in an ultrasonic cleaning machine, the ultrasonic frequency is 30KHz, the ultrasonic intensity is 200W, and the processing time is 8 minutes. At the same time, the binary copolymer of low molecular weight acrylic acid and maleic anhydride is added to inhibit the dispersion of phosphorus-containing minerals, and the dosage is 3000g / t.

[0041] (2) Rough selection by flotation: the processed molybdenum concentrate is used as raw material, and then put into the flotation machine for rough separation operation to obtain rough separation concentrate and rough separation tailings, which are used as raw materials for...

Embodiment 3

[0045] With Mo content as 48.45%, P content 0.092% phosphorus-containing molybdenum concentrate exceeding the standard as raw material, utilize the technology of the present invention, carry out following steps, as figure 1 :

[0046] (1) Ultrasonic treatment: The high-phosphorus molybdenum concentrate is subjected to ultrasonic dispersion cleaning treatment in an ultrasonic cleaning machine, the ultrasonic frequency is 80KHz, the ultrasonic intensity is 250W, and the treatment time is 6 minutes. At the same time, low molecular weight sodium polyacrylate is added to inhibit the dispersion of phosphorus-containing minerals, and the dosage is 3000g / t.

[0047] (2) Rough selection by flotation: the processed molybdenum concentrate is used as raw material, and then put into the flotation machine for rough separation operation to obtain rough separation concentrate and rough separation tailings, which are used as raw materials for further selection , roughing tailings as raw mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com