Manganese-magnesium low-grade phosphate flotation process

A low-grade, magnesia-based technology, applied in flotation, solid separation, etc., can solve the problems of lower quality and productivity, poor dissociation, and fine particle size of embedded cloth, and achieve the effect of improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

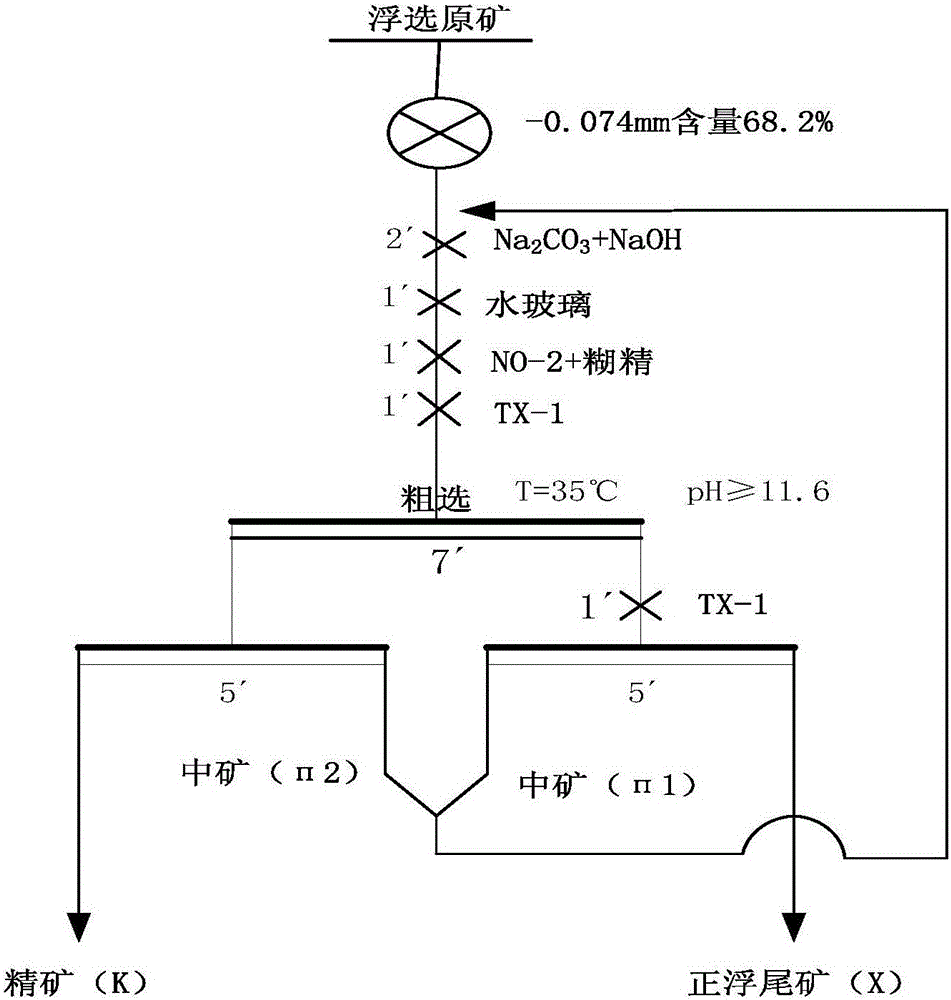

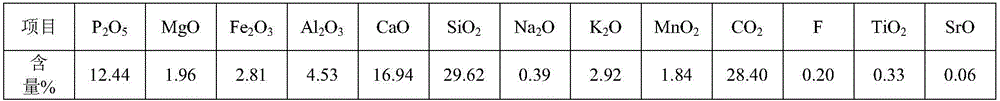

[0022] A kind of flotation process of manganese and magnesium low-grade phosphate rock, its process flow is shown in figure 1 , the manganese and magnesium low-grade phosphate rock used is a manganese low-grade phosphate rock in Hubei, and its main chemical composition is:

[0023]

[0024] Specific steps are as follows:

[0025] Manganese-magnesium low-grade phosphate rock is crushed to -2mm, and then grinded with a grinding machine until the mass fraction of ore particles with a grinding fineness of -0.074mm accounts for about 68%, so that phosphorus minerals and gangue Minerals, including manganese minerals, carbonate minerals and other monomers, are dissociated, and water is added to adjust the slurry until the solid concentration in the slurry is 34g / L, and then flow into the mixing tank, and a pH regulator (which is composed of sodium carbonate and sodium hydroxide) is added to the slurry. It is mixed with a mass ratio of 3:1, the dosage is 6.0kg / t relative to the ra...

Embodiment 2

[0028] A kind of flotation process of manganese and magnesium low-grade phosphate rock, the specific steps are as follows:

[0029] Manganese and magnesium low-grade phosphate rock is crushed and ground (same as in Example 1), so that phosphorus minerals and gangue minerals, including manganese minerals and carbonate minerals, are dissociated, and water is added to make slurry until solid The concentration is 34g / L, and then it flows into the mixing tank, and a pH regulator is added to the pulp (it is made of sodium carbonate and sodium hydroxide mixed at a mass ratio of 3:1, and the dosage relative to the raw ore is 5.0kg / t) and water glass (the ratio of the amount to the raw ore is 0.8kg / t), adjust the pH value of the slurry to 11.6, and then add the inhibitor (it is mixed by the mass ratio of carbonate inhibitor NO-2 and dextrin at a ratio of 1:1 Formed, the ratio of the amount relative to the raw ore is 1.2kg / t) and the positive flotation collector (anionic fatty acid (soa...

Embodiment 3

[0031] A kind of flotation process of manganese and magnesium low-grade phosphate rock, the specific steps are as follows:

[0032] Manganese and magnesium low-grade phosphate rock is crushed and ground (same as in Example 1), so that phosphorus minerals and gangue minerals, including manganese minerals and carbonate minerals, are dissociated, and water is added to make slurry until solid The concentration is 34g / L, and then it flows into the mixing tank, and a pH regulator is added to the slurry (it is composed of sodium carbonate and sodium hydroxide mixed at a mass ratio of 3:1, and the dosage relative to the raw ore is 7.0kg / t) and water glass (the ratio of the amount to the raw ore is 0.8kg / t), adjust the pH value of the slurry to 11.8, and then add the inhibitor (it is mixed by the mass ratio of carbonate inhibitor NO-2 and dextrin at 1:1 Formed, the ratio of the amount relative to the raw ore is 1.6kg / t) and the positive flotation collector (anionic fatty acid (soap) co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com