Lithium recovery from phosphate minerals

a technology of phosphate minerals and lithium, which is applied in the direction of improving process efficiency, etc., can solve the problems of amblygonite, amblygonite is problematic, and the prior art effort has not involved direct leaching in the acidic media of the mineral, so as to achieve a higher lithium recovery and reduce the volume of the liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

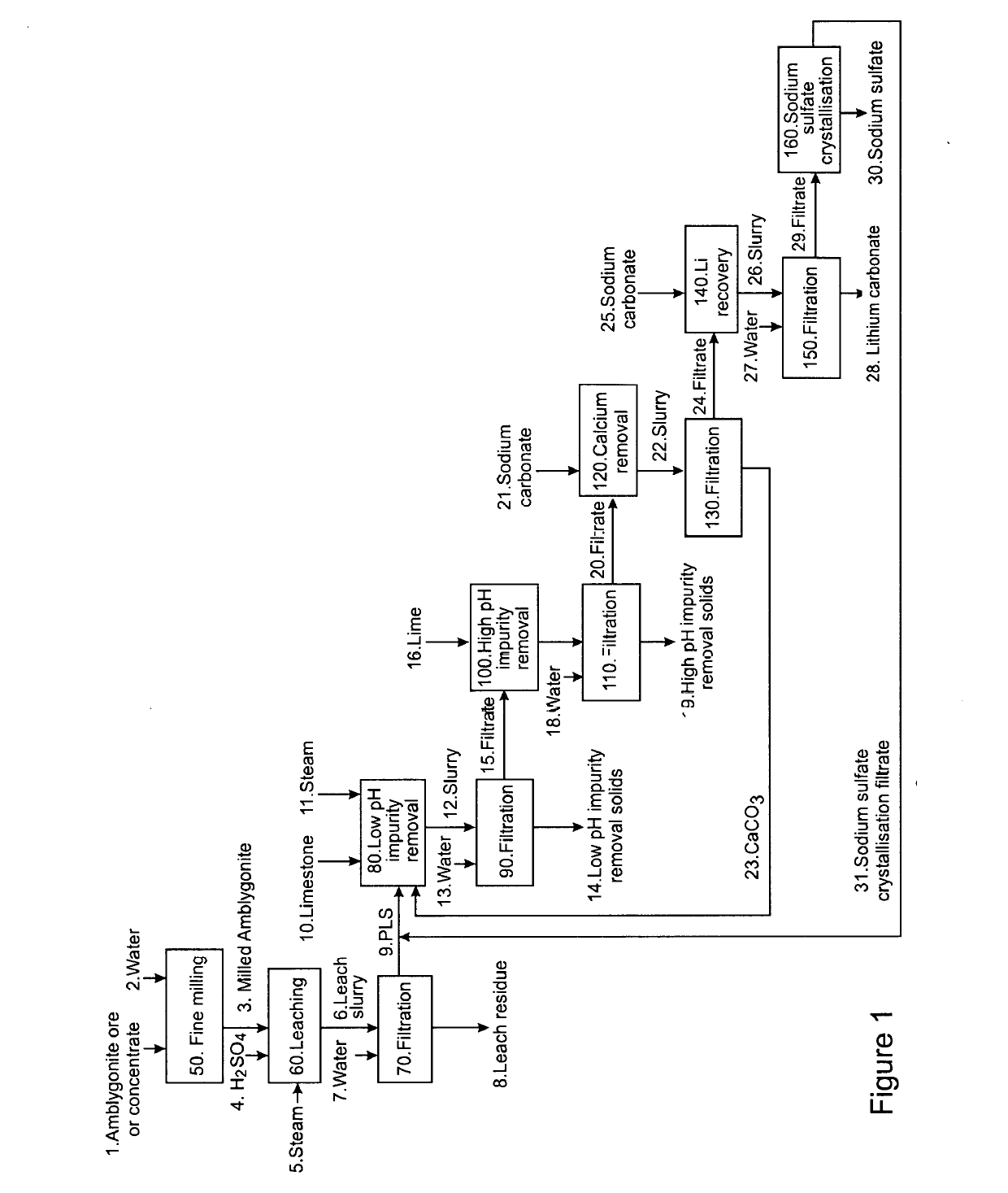

[0057]The process of the present invention comprises a novel and improved combination of operating steps, one or more of which may have been used previously, in other combinations and for other purposes, in mineral processing and hydrometallurgical processes.

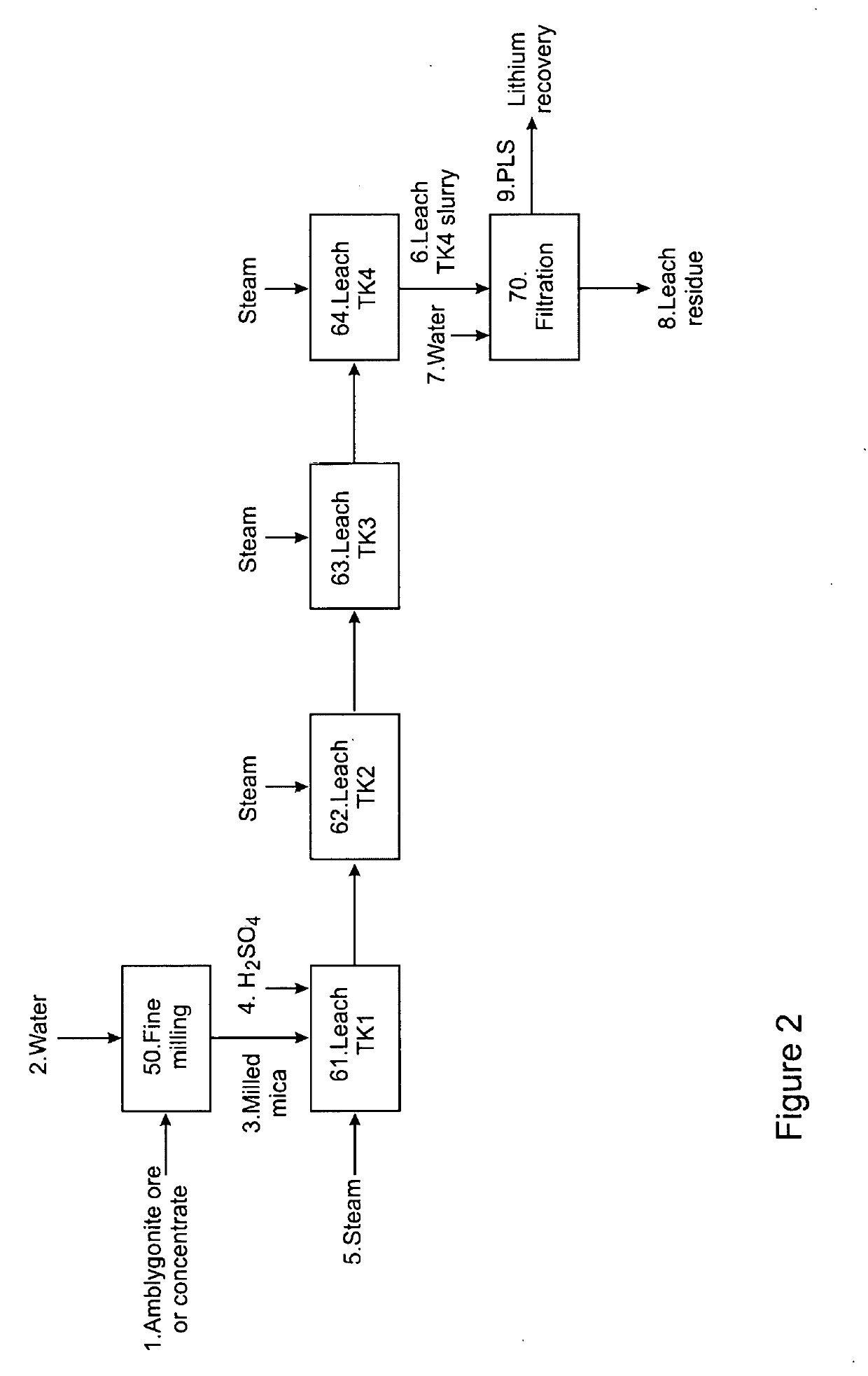

[0058]In very general terms, in one embodiment of the present invention, a lithium and phosphate containing mineral, for example amblygonite, is pre-concentrated, if required, by a mineral separation process, for example flotation. The amblygonite ore or concentrate is then subject to a pre-treatment step comprising, for example, fine milling. The lithium, sodium, phosphate, aluminium and fluoride present in amblygonite are extracted by strong sulfuric acid leaching, producing a leach liquor or pregnant leach solution containing lithium, sodium, phosphate, aluminium and fluoride. Lithium is separated from residual impurities, including, but not limited to, sulfuric acid, phosphate, aluminium, iron, manganese, calcium, sodium and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| retention time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com