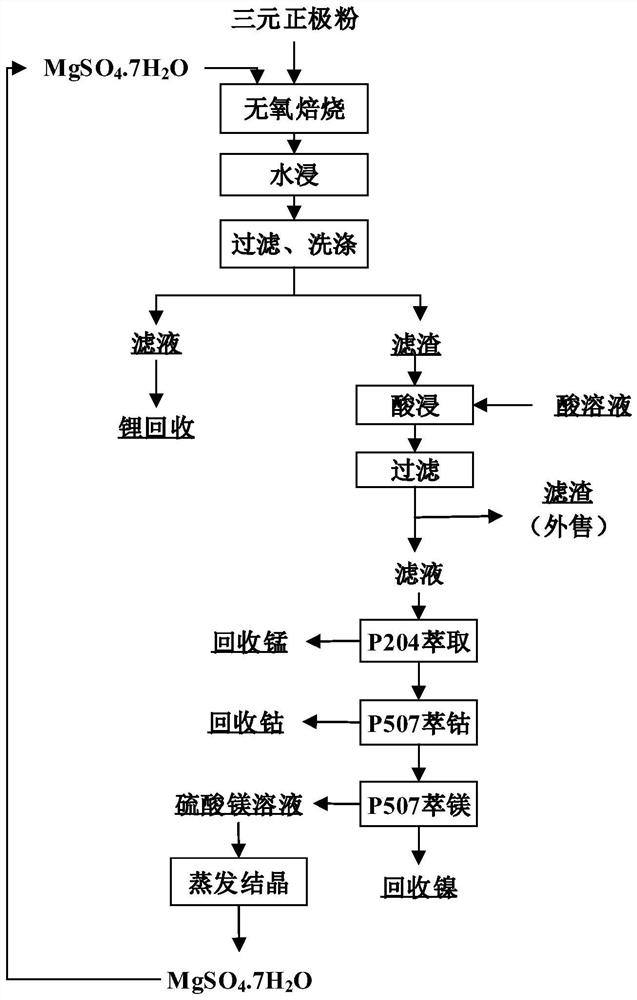

A method for the comprehensive recovery of valuable metals from ternary lithium battery cathode materials based on magnesium salt cycle

A ternary lithium battery and positive electrode material technology, applied in battery recycling, recycling technology, recycling by waste collectors, etc., can solve the problem of the direction of sulfate additives, the final treatment method is not clear, the final recovery rate is only 90%, and it is difficult to be economical Effectively deal with such problems as to achieve the effect of large promotion and application value, significant environmental and economic benefits, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Sulfation roasting: weigh 30gMgSO 4 .7H 2 O and 50g of ternary lithium battery cathode powder were mixed, and calcined at 900°C for 1h under anaerobic conditions to obtain 53.6g of calcined slag.

[0032] (2) Water immersion: mix the calcined material with water for water immersion, the liquid-solid ratio of water immersion is 3:1mL / g, the temperature is 50°C, and the time is 0.5h. After water immersion and filtration, a lithium-containing solution with a lithium concentration of 9.8 g / L was obtained. 41.84 g of filter residue was obtained, which contained 0.019% lithium, 15.4% nickel, 9.3% cobalt and 44.3% manganese.

[0033] (3) Concentrate and remove impurities from the lithium-containing filtrate, then add sodium carbonate to carry out alkali precipitation to obtain a lithium carbonate product.

[0034] (4) Acid leaching: Take the water leaching slag in step (2), add water according to the liquid-solid ratio of 5:1mL / g, add concentrated sulfuric acid according ...

Embodiment 2

[0041] (1) Sulfation roasting: weigh 35gMgSO 4 .7H 2 O, 50g of ternary lithium battery positive electrode powder, mixed, and roasted at 300°C for 3 hours under anaerobic conditions to obtain 56.9g of roasted slag.

[0042] (2) Water immersion: mix the calcined material with water for water immersion, the liquid-solid ratio of water immersion is 4:1mL / g, the temperature is 60°C, and the time is 1h. After water immersion and filtration, a lithium-containing solution with a lithium concentration of 6.97 g / L was obtained. 42.4 g of filter residue was obtained, which contained 0.015% lithium, 14.4% nickel, 8.8% cobalt and 41.7% manganese.

[0043] (3) Concentrate and remove impurities from the lithium-containing filtrate, add sodium carbonate to carry out alkali precipitation to obtain lithium carbonate product

[0044] (4) Acid leaching: take the water leaching residue in step (2), add water according to the liquid-solid ratio of 4:1mL / g, add concentrated sulfuric acid accordin...

Embodiment 3

[0051] (1) Sulfation roasting: weigh 50gMgSO 4 .7H 2 O, 50g of ternary lithium battery cathode powder, mixed, and roasted at 700°C for 5h under anaerobic conditions to obtain 63.39g of roasted slag.

[0052] (2) Water immersion: mix the calcined material with water for water immersion, the liquid-solid ratio of water immersion is 5:1mL / g, the temperature is 80°C, and the time is 1h. After water immersion and filtration, a lithium-containing solution with a lithium concentration of 6.59 g / L was obtained. 41.61 g of filter residue was obtained, which contained 0.01% lithium, 13.7% nickel, 8.3% cobalt and 39.4% manganese.

[0053] (3) Concentrate and remove impurities from the lithium-containing filtrate, add sodium carbonate to carry out alkali precipitation to obtain a lithium carbonate product.

[0054] (4) Acid leaching: take the water leaching slag in step (2), add water according to the liquid-solid ratio of 3:1mL / g, add concentrated sulfuric acid according to the acid-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com