Recovery method of waste ternary lithium battery positive electrode material

A ternary lithium battery and positive electrode material technology, which is applied in battery recycling, waste collector recycling, recycling technology, etc., can solve the problems of ternary lithium battery recycling methods to be studied, poor economy, hazards, etc., to achieve high value The effects of cleaning and recycling, reducing the difficulty of metal separation, and improving recycling economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

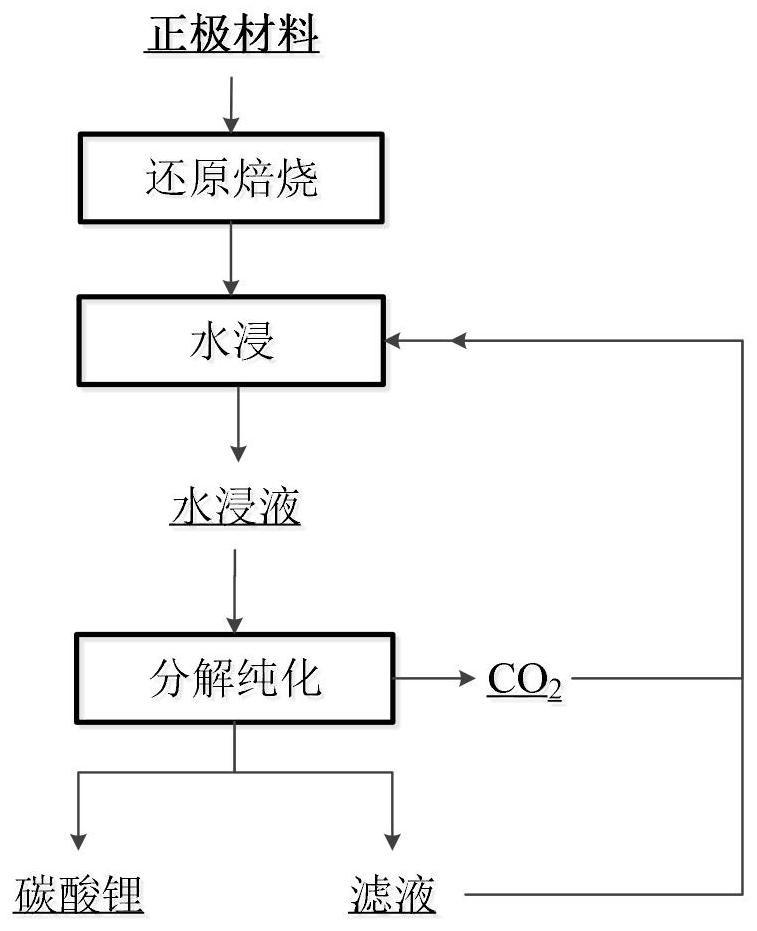

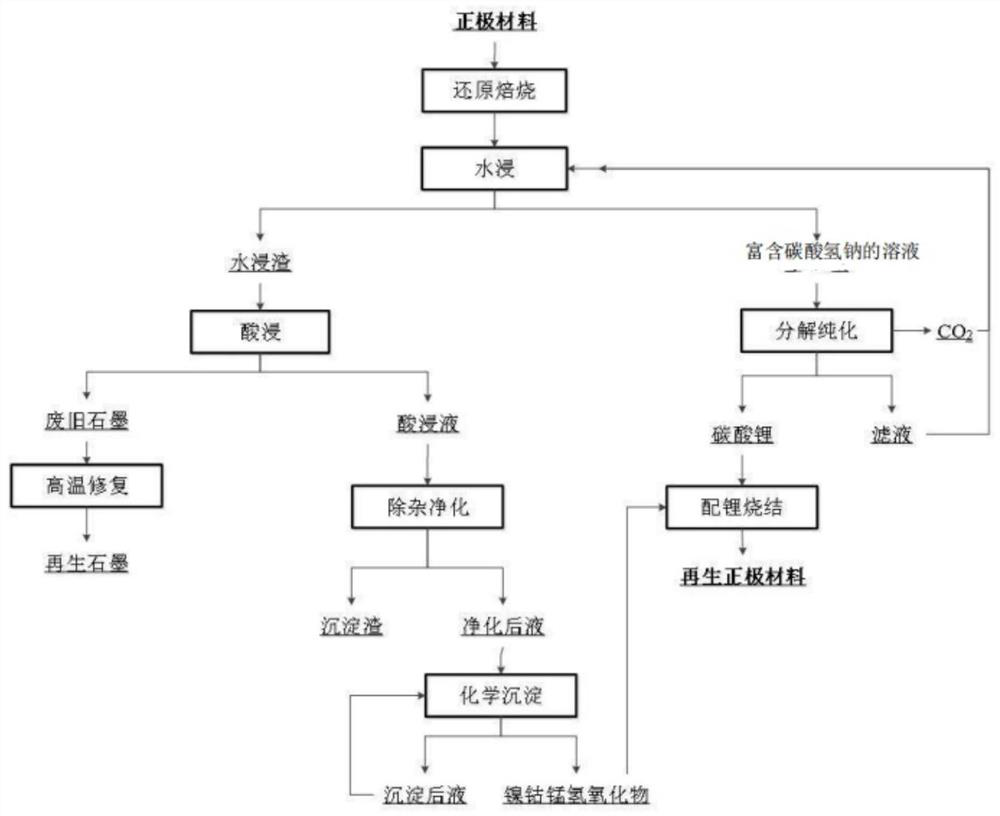

[0036] Get ternary lithium battery positive and negative electrode mixture 100g (negative electrode material accounts for 32%), in CO 2 Roast at 600°C for 2 hours under atmosphere, and then cool to obtain the roasted product, add 1000ml of water, leaching at 50°C for 2 hours, and feed CO at 1.0L / min at the same time 2 , The leaching rate of lithium is 85.6%. After filtering, water leaching liquid and water leaching residue are obtained, and other metals are not leached.

[0037] The resulting water immersion solution was heated at 80 °C for 3 h and CO was collected 2 , filtered to obtain lithium carbonate and the filtrate, the resulting CO 2 And the filtrate is returned to the water immersion process for reuse. Add 450ml of water (liquid-solid ratio 8:1) and 12.5ml of concentrated sulfuric acid to the obtained water leaching residue, and leaching at 90°C for 3 hours, the leaching rates of nickel-cobalt-manganese-copper-aluminum are 99.5%, 99.4%, 99.1%, 99.3% respectively. %...

Embodiment 2

[0042] Get ternary lithium battery positive and negative electrode mixture 100g (negative electrode material accounts for 30%), in CO 2 Roast at 650°C for 3 hours under the atmosphere, and then cool to obtain the roasted product, add 1000ml of water, leaching at 75°C for 2 hours, and feed CO at 1.5L / min at the same time 2 , The leaching rate of lithium is 92.3%. After filtering, water leaching liquid and water leaching residue are obtained, and other metals are not leached.

[0043] The resulting water immersion solution was heated at 80 °C for 1 h and CO was collected 2 , filtered to obtain lithium carbonate and the filtrate, the resulting CO 2 And the filtrate is returned to the water immersion process for reuse. Add 480ml of water (liquid-solid ratio 9:1) and 16.6ml of concentrated sulfuric acid to the obtained water leaching residue, and leaching at 70°C for 2h, the leaching rates of nickel-cobalt-manganese-copper-aluminum are 99.3%, 99.4%, 99.2%, respectively. 99.2%, 9...

Embodiment 3

[0048] Get ternary lithium battery positive and negative electrode mixture 100g (negative electrode material accounts for 35%), in CO 2 Roast at 500°C for 4 hours under atmosphere, and then cool to obtain the roasted product, add 1000ml of water, leaching at 25°C for 5 hours, and feed CO at 2.0L / min at the same time 2 , the leaching rate of lithium is 88.6%. After filtering, water leaching liquid and water leaching residue are obtained, and other metals are not leached.

[0049] The resulting water immersion solution was heated at 70 °C for 5 h and CO was collected 2 , filtered to obtain lithium carbonate and the filtrate, the resulting CO 2 And the filtrate is returned to the water immersion process for reuse. Add 320ml of water (liquid-solid ratio 6:1) and 9.9ml of concentrated sulfuric acid to the obtained water leaching residue, and leaching at 90°C for 3h, the leaching rates of nickel-cobalt-manganese-copper-aluminum are 99.2%, 99.3%, 99.5%, 98.6%, respectively. %, 99....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com