Phosphate extraction agent and method for extracting and separating lithium-manganese leaching solution by using phosphate extraction agent

The technology of extracting agent and phosphate ester is applied in the field of extracting agent of phosphate ester and its extraction and separation of lithium manganese leaching solution, which can solve the problems such as the adverse effect of separation and recovery of lithium salt product purity, incomplete separation of lithium manganese and low current efficiency, etc. The effect of eliminating saponification waste liquid, efficient green extraction, and improving lithium recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The initial pH value of the lithium-manganese leaching solution is 3, and the contents of valuable metals are Li 20g / L and Mn 40g / L. Follow the steps below for clean and efficient extraction and separation of lithium and manganese in a mixed-settler tank:

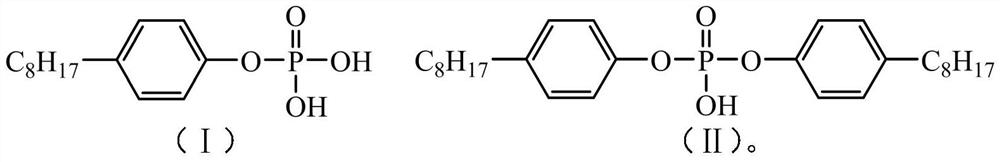

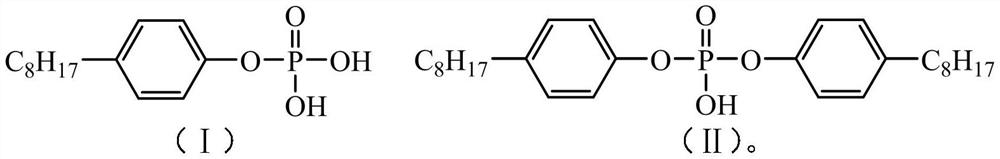

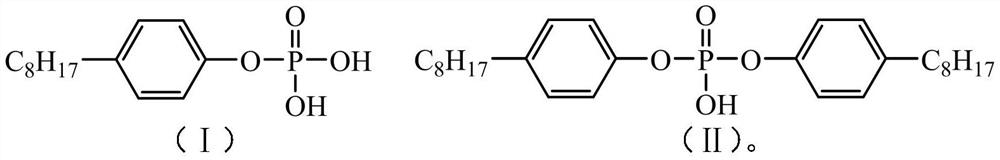

[0043] (1) Prepare and extract the organic phase: select dialkyl phosphate (II) as the extractant, n-butanol as the modifier, and sulfonated kerosene as the diluent, according to "40% extractant + 10% modifier + dilution The volume ratio of agent 50%" is configured to extract the organic phase.

[0044] (2) Manganese extraction: using the extracted organic phase configured in step (1), under the process conditions that the O / A ratio is 1:2, the extraction temperature is 40°C, and the extraction time is 10min, the lithium-containing manganese leachate is extracted. 8-stage extraction of manganese to obtain manganese-loaded organic phase and lithium-containing raffinate. Through detection and calculation, the extract...

Embodiment 2

[0048] The initial pH value of the lithium manganese leach solution is 4, and the contents of valuable metals are Li 18g / L and Mn 8g / L respectively. Follow the steps below for clean and efficient extraction and separation of lithium and manganese in a mixed-settler tank:

[0049] (1) Prepare and extract the organic phase: select monoalkyl phosphate (I) as the extractant, n-butanol as the modifier, and sulfonated kerosene as the diluent, according to "35% extractant + 15% modifier + dilution The volume ratio of agent 50%" is configured to extract the organic phase.

[0050] (2) Manganese extraction: using the extracted organic phase configured in step (1), under the process conditions that the O / A ratio is 1:3, the extraction temperature is 45°C, and the extraction time is 6min, the lithium-containing manganese leachate is extracted. Manganese is extracted in three stages to obtain a manganese-loaded organic phase and a lithium-containing raffinate. Through detection and calc...

Embodiment 3

[0054] The initial pH value of the lithium manganese leach solution is 2, and the contents of valuable metals are Li 10g / L and Mn 30g / L respectively. Follow the steps below for clean and efficient extraction and separation of lithium and manganese in a mixed-settler tank:

[0055] (1) Prepare and extract the organic phase: select "20wt% monoalkyl phosphate (I) + 80wt% dialkyl phosphate (II)" as the extractant, isobutanol as the modifier, and sulfonated kerosene as the diluent According to the volume ratio of "extractant 40% + modifier 15% + diluent 45%", the organic phase is extracted.

[0056] (2) Manganese extraction: using the extracted organic phase configured in step (1), under the process conditions that the O / A ratio is 1:1, the extraction temperature is 40°C, and the extraction time is 10min, the lithium-containing manganese leachate is extracted. Manganese is extracted in 4 stages to obtain a manganese-loaded organic phase and a lithium-containing raffinate. Through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com