A method based on combined leaching of spodumene by microwave and pressure field

A spodumene and pressure field technology, which is applied in the field of spodumene leaching based on microwave and pressure field, can solve the problems of narrow transformation temperature range and low transformation rate of spodumene ore, so as to reduce the hidden danger of melting and ringing, Short process, good process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

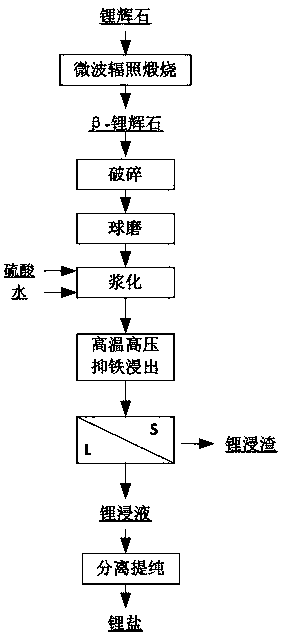

[0033] A method based on microwave and pressure field combined leaching spodumene, comprising the steps:

[0034] 1) Grinding: use spodumene concentrate as raw material, grind, add coal powder of 2% of the total mass of raw material, mix evenly, and obtain a mixture;

[0035] 2) Crystal transformation

[0036] Using the silicon carbide lining the rotary kiln as the heat source carrier, heat the mixture obtained in step 1) to 1000°C under the condition of microwave power of 1500w, and then use microwave irradiation to transform the crystal form at a constant temperature of 1000°C 15min, then cooled to room temperature to obtain β-type spodumene;

[0037] 3) Leaching

[0038] Grind the β-type spodumene obtained in step 2), and add water to make a slurry to obtain a slurry; put the slurry into an autoclave, then add sulfuric acid with a concentration of 2%, and under the conditions of a pressure of 0.2Mpa and 120°C, the stirring speed is 500r / min, leaching for 20min to obtain ...

Embodiment 2

[0041] A method based on microwave and pressure field combined leaching spodumene, comprising the steps:

[0042] 1) Grinding: use spodumene concentrate as raw material, grind, add coal powder with 8% of the total mass of raw material, mix evenly, and obtain a mixture;

[0043] 2) Crystal transformation

[0044] Using the silicon carbide lining the rotary kiln as the heat source carrier, the mixture obtained in step 1) is heated to 1180°C under the condition of microwave power of 4000w, and then the crystal form is transformed under the constant temperature condition of 1180°C by microwave irradiation. 120min, then cooled to room temperature to obtain β-type spodumene;

[0045] 3) Leaching

[0046] Grind the β-type spodumene obtained in step 2), and add water to make a slurry to obtain a slurry; put the slurry into an autoclave, then add sulfuric acid with a concentration of 10%, and under the conditions of a pressure of 1.6Mpa and 200°C, the stirring speed is 1800r / min, le...

Embodiment 3

[0049] A method based on microwave and pressure field combined leaching spodumene, comprising the steps:

[0050] 1) Grinding: use spodumene concentrate as raw material, grind, add coal powder with 5% of the total mass of raw material, mix evenly, and obtain a mixture;

[0051] 2) Crystal transformation

[0052] Using the silicon carbide lining the rotary kiln as the heat source carrier, heat the mixture obtained in step 1) to 1100°C under the condition of microwave power of 2500w, and then use microwave irradiation to transform the crystal form under the constant temperature condition of 1100°C 60min, then cooled to room temperature to obtain β-type spodumene;

[0053] 3) Leaching

[0054] Grind the β-type spodumene obtained in step 2), and add water to make a slurry to obtain a slurry; put the slurry into an autoclave, then add sulfuric acid with a concentration of 6%, and under the conditions of a pressure of 0.8Mpa and 160°C, the stirring speed is 1100r / min, leaching fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com