Method for preparing ammonium alum from sulfuric acid method lithium extraction leaching solution

A technology of leachate and sulfuric acid method, applied in aluminum sulfate, chemical instruments and methods, aluminum sulfur compounds, etc., can solve the problems that aluminum ions cannot be effectively comprehensively recycled, large losses, and high aluminum ion content, and improve the comprehensive recovery of aluminum ions. The effect of utilization and improvement of lithium recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

[0033] The raw ore is a lepidolite resource in Henan, and the main valuable elements in the raw ore sample are lithium, Li 2 The O content is 6.39%. The main minerals are lepidolite, feldspar, pyrite and quartz. The chemical analysis of the main elements of the ore is shown in Table 3.

[0034] Table 3 Results of multi-element analysis of raw ore

[0035] element / % Li 2 o

SiO 2

K 2 o

Na 2 o

MnO 2

content 6.39 56.56 7.54 0.21 0.20 element al 2 o 3

Fe 2 o 3

CaO MgO P 2 o 5

content / % 25.32 0.04 0.97 0.079 0.11

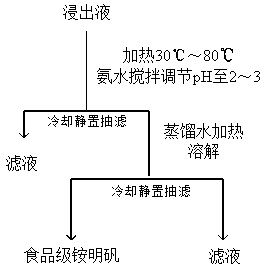

[0036] Process flow chart see figure 1 As shown, the steps are as follows:

[0037] (1) Sulfuric acid method is filtered to obtain the leachate;

[0038] (2) Add ammonia water with a concentration of 20%-25% to the leachate, and stir to adjust the pH to 2.64;

[0039] (3) Let the leaching solution stand at room temperature for 36 hours to crystallize, and filter with sucti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com