Storing-sorting-integrated whole-input-scattered-output logistics system and method

A logistics system and pallet technology, applied in the field of logistics, can solve problems such as low efficiency, achieve the effect of reducing movement, low requirements for site use conditions, and easy transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0026] The present invention proposes a logistics system that integrates storage and picking, and integrates all in and zero out. The system sets storage and sorting areas together, including a storage and sorting functional area, a picking robot, a main conveyor belt, and a controller.

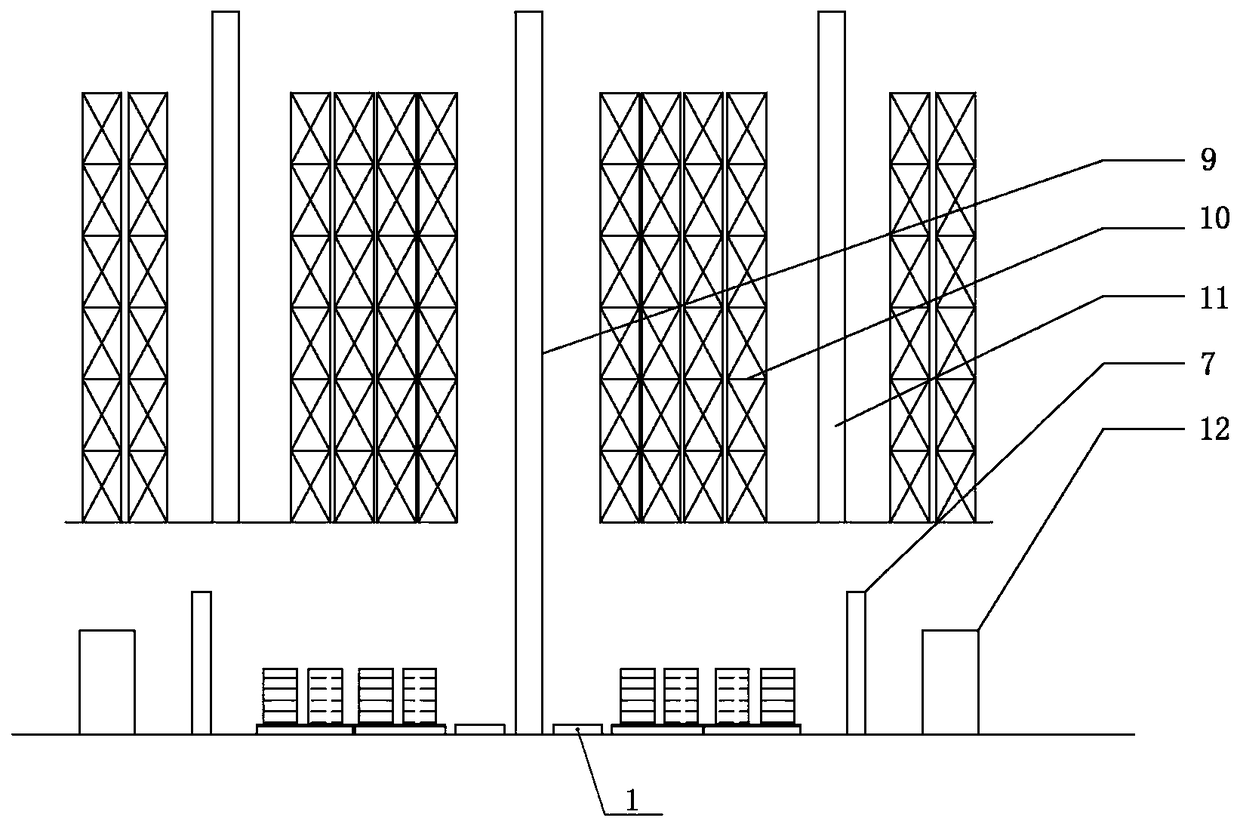

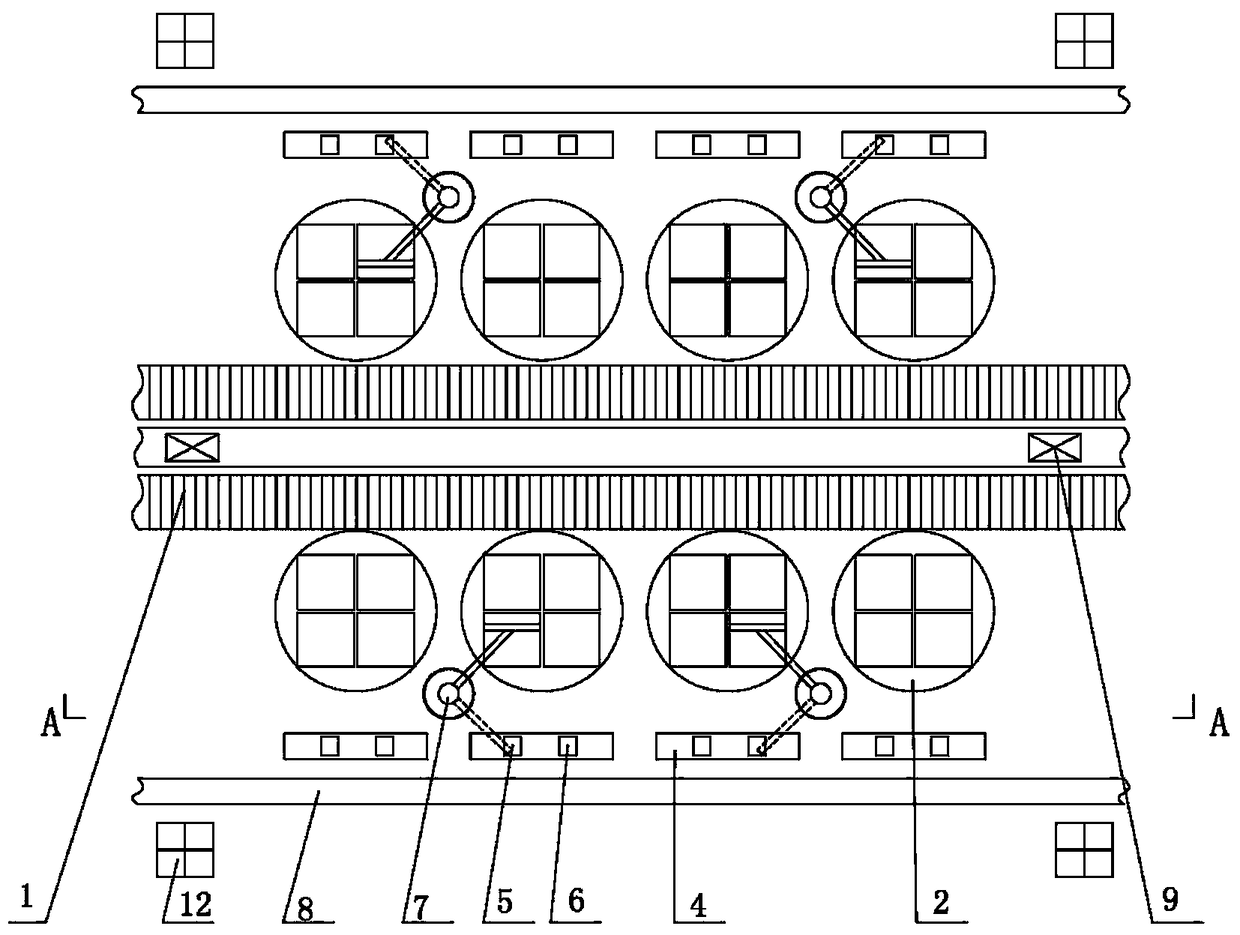

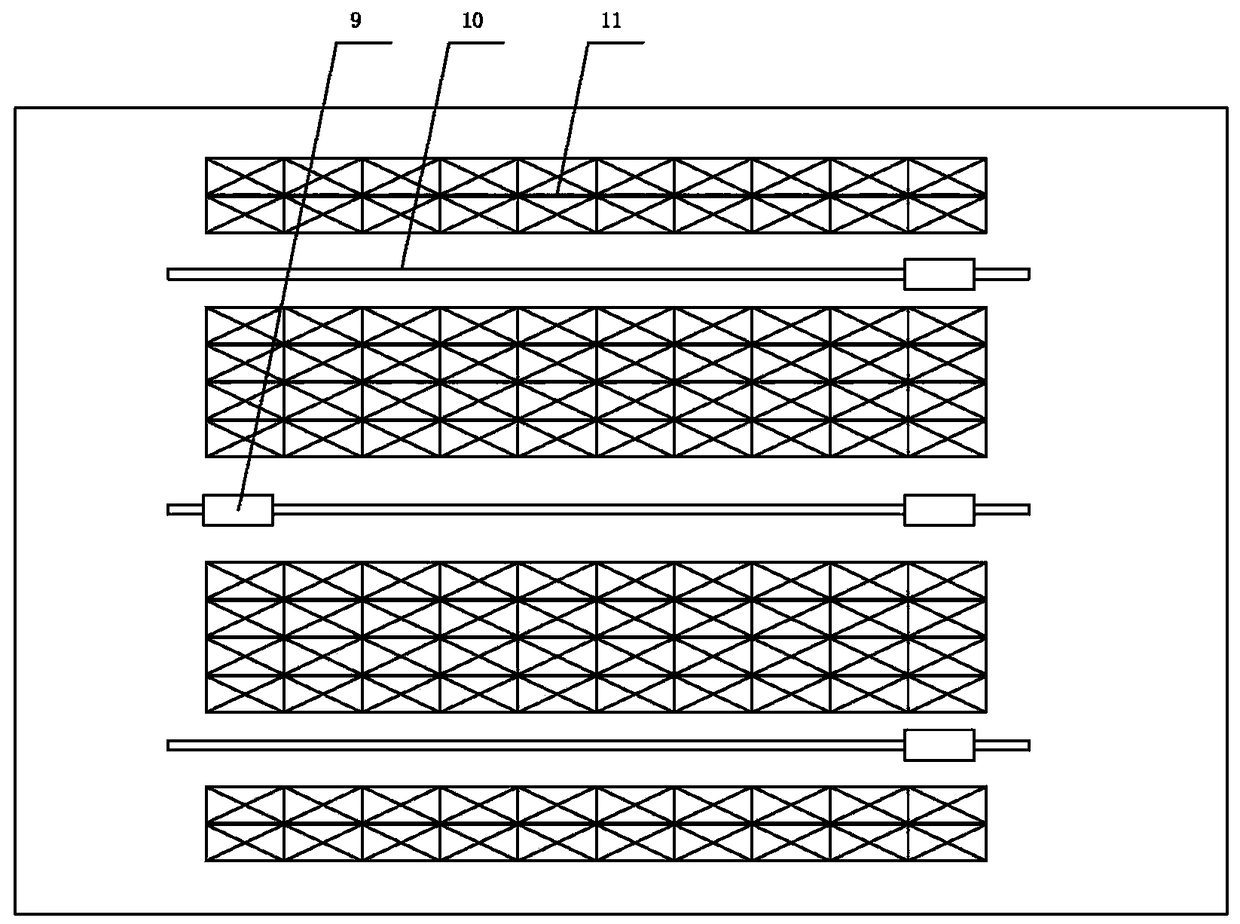

[0027] Such as figure 1 and figure 2 As shown, the storage and picking functional area includes a load transmission line 1 and multiple sets of automatic turntables 2. Several trays 3 can be placed on each automatic turntable. The trays loaded with commodities move through the load transmission line and are pushed into the automatic turntable by the mechanism on it. , when the goods on the pallet are picked, the empty pallet is taken away by the mechanism on the load transmission line and sent to the pallet stacker 12 places.

[0028] The picking robot 7 is used for sorti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com