Micro-ohm resistance measurement system based on LabVIEW developing platform

A development platform and resistance measurement technology, applied in the direction of measuring devices, measuring electrical variables, measuring resistance/reactance/impedance, etc., can solve the problems of explosion, low measurement accuracy of direct current method, and inability to directly read, and achieve measurement accuracy and resolution High efficiency, flexible and convenient software programming, and good specificity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings.

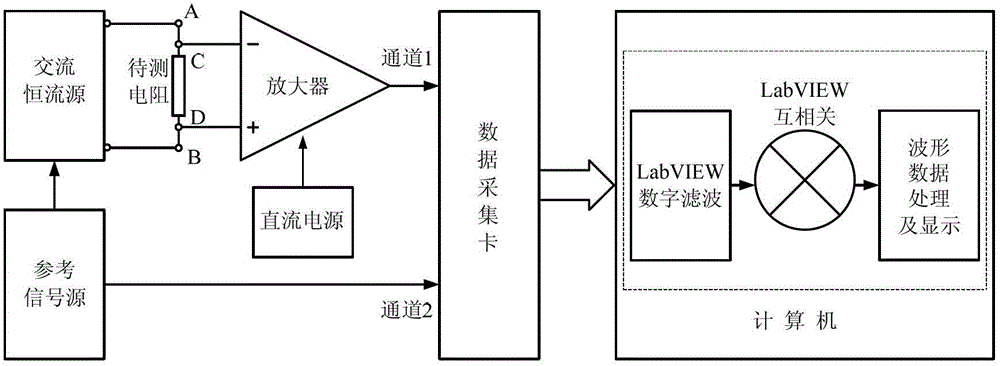

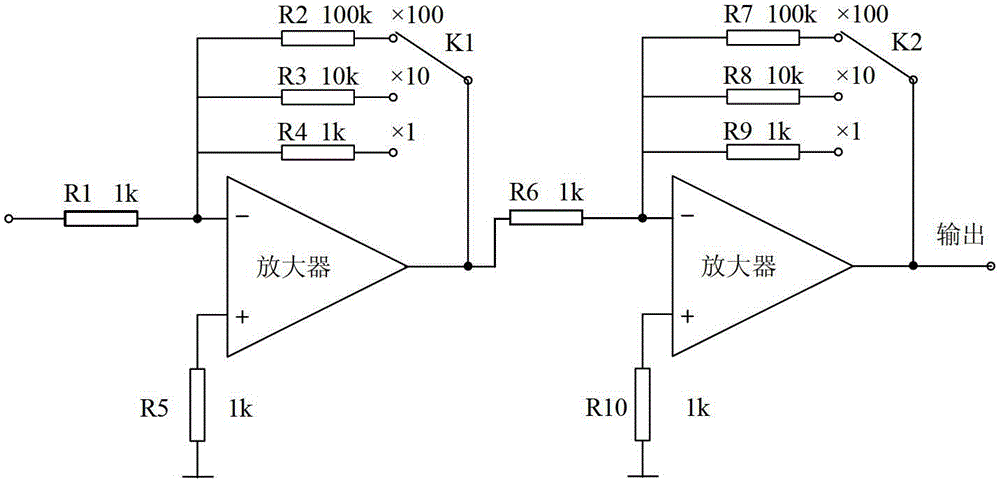

[0020] The micro-ohm-level resistance measurement system based on the LabVIEW development platform includes two parts: the resistance signal detection hardware system and the LabVIEW cross-correlation analysis and processing software system. The resistance signal detection hardware system consists of an AC constant current source, a reference signal source, a resistance to be measured, a low-noise preamplifier, a data acquisition card, a DC power supply and a computer. The LabVIEW signal cross-correlation analysis and processing software system consists of a data acquisition module, a LabVIEW digital filter module, a LabVIEW cross-correlation module and a data post-processing module, all of which are developed based on the LabVIEW development platform and its subsidiary software packages.

[0021] The output current generated by the AC constant current source...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com