Thin strip continuous casting billet surface defect sinusoidal grating phase shifting detection device and method

A sine grating, phase shift detection technology, applied in measuring devices, using optical devices, optical testing flaws/defects, etc., can solve the problems of high cost, low degree of automation, high work intensity, etc. The effect of improving the level of automation and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with specific embodiments.

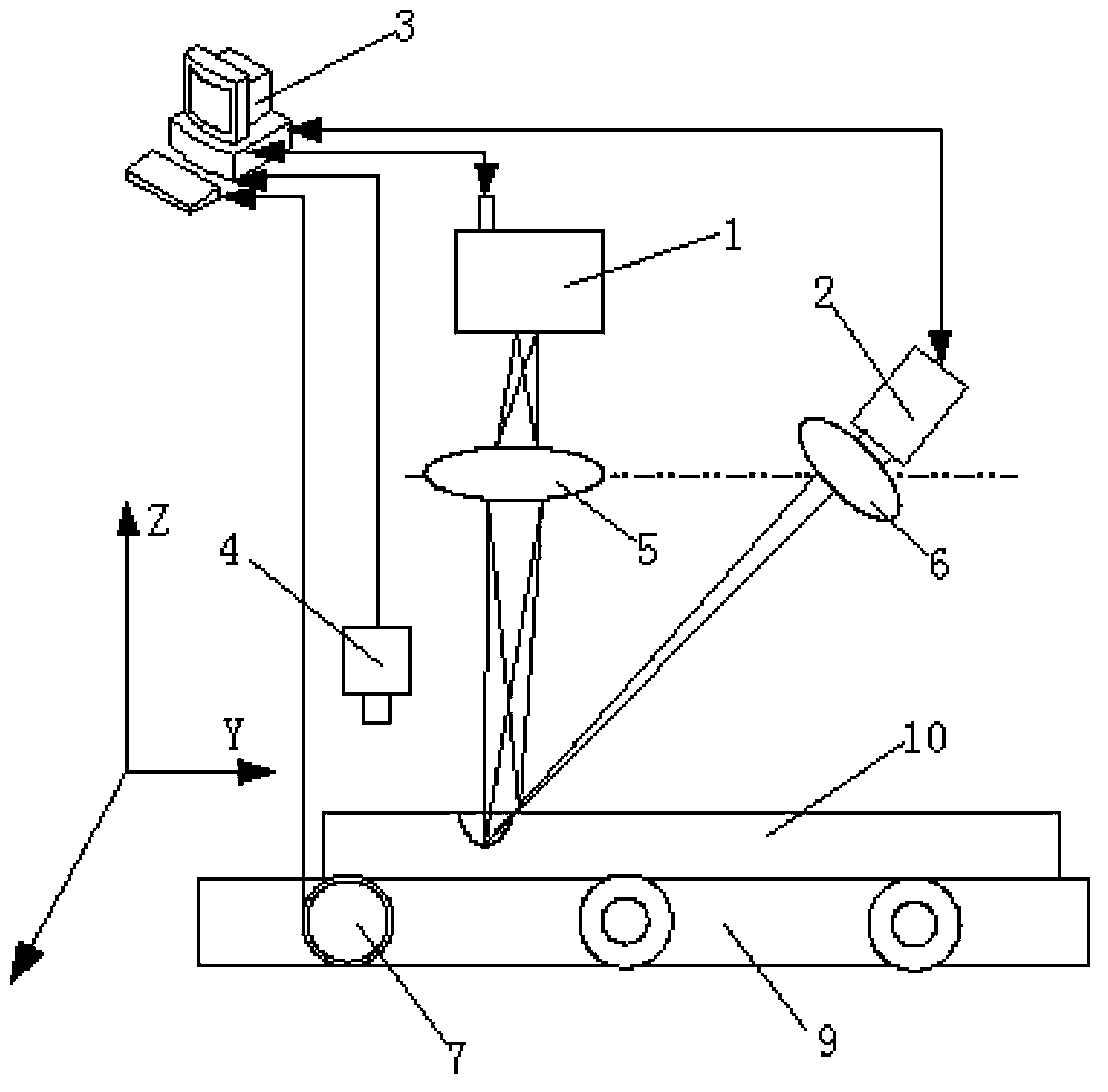

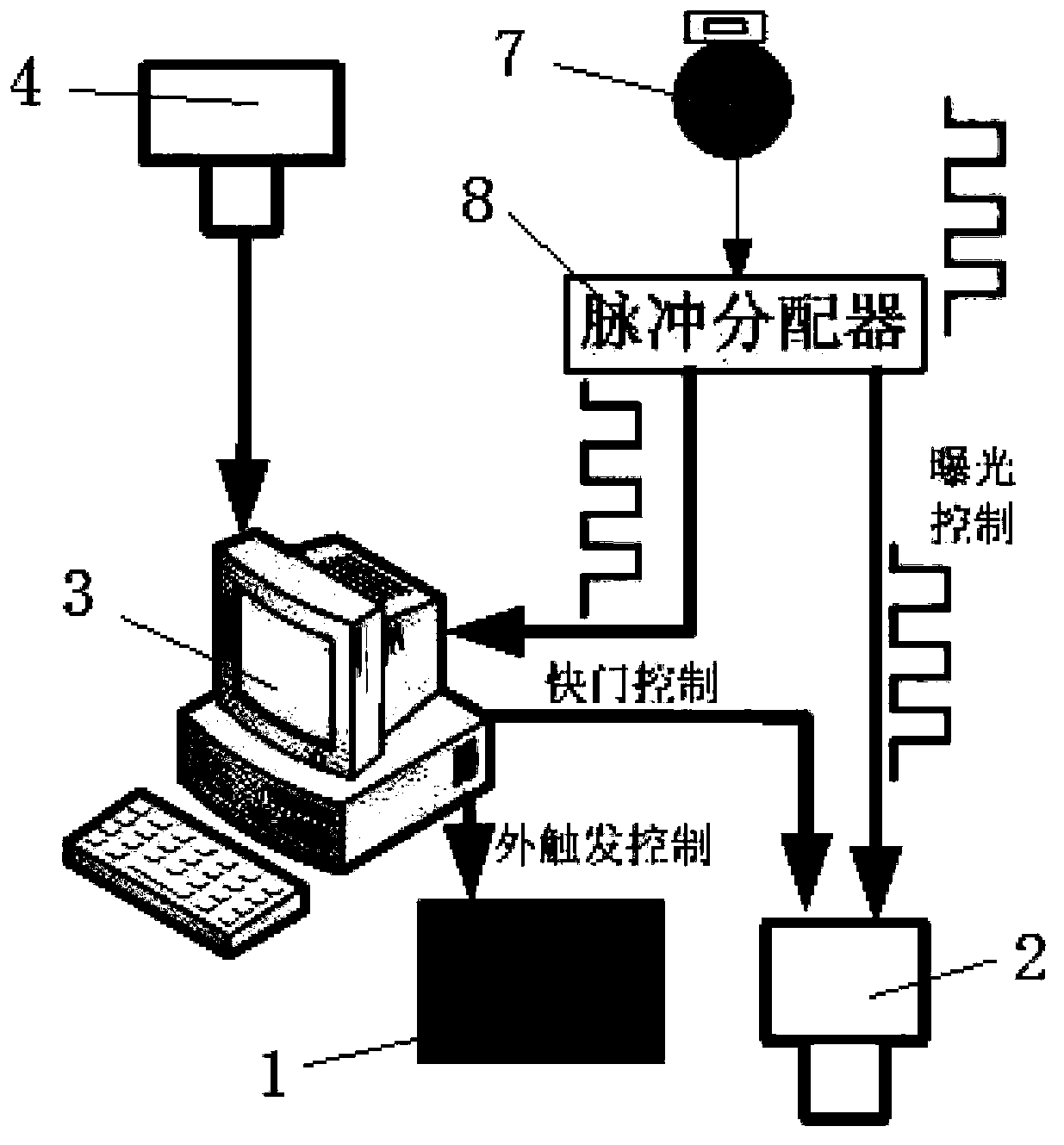

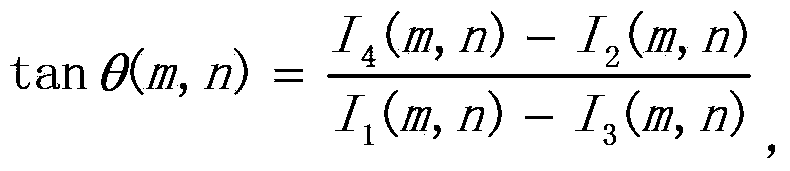

[0042] Such as figure 1 and figure 2 As shown, a sinusoidal grating phase-shift detection device for surface defects of thin strip continuous casting slabs includes a projector 1 and an industrial camera 2. The projector 1 and the industrial camera 2 are respectively connected to a computer 3 in two directions, and an infrared thermometer 4 is also included. , the projection front of the projector 1 is provided with a first lens 5, and a second lens 6 is installed in front of the industrial camera 2, and the aperture centers of the first lens 5 and the second lens 6 are on the same horizontal line, and the first lens 5 The imaging vertical centerline is not on the same straight line as the imaging centerline of the second lens 6, and also includes a rotary pulse encoder 7 installed on the nip roller 9, and the output terminal of the rotary pulse encoder 7 pulse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com