Lonky detection method of aspheric surface with heavy calibre

A detection method and an aspheric surface technology, applied to measuring devices, instruments, optical devices, etc., can solve the problems of low measurement efficiency, inaccessibility, and measurement result errors, and achieve simple detection structure, convenient and fast operation, and anti-aliasing shape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings, working principles and embodiments.

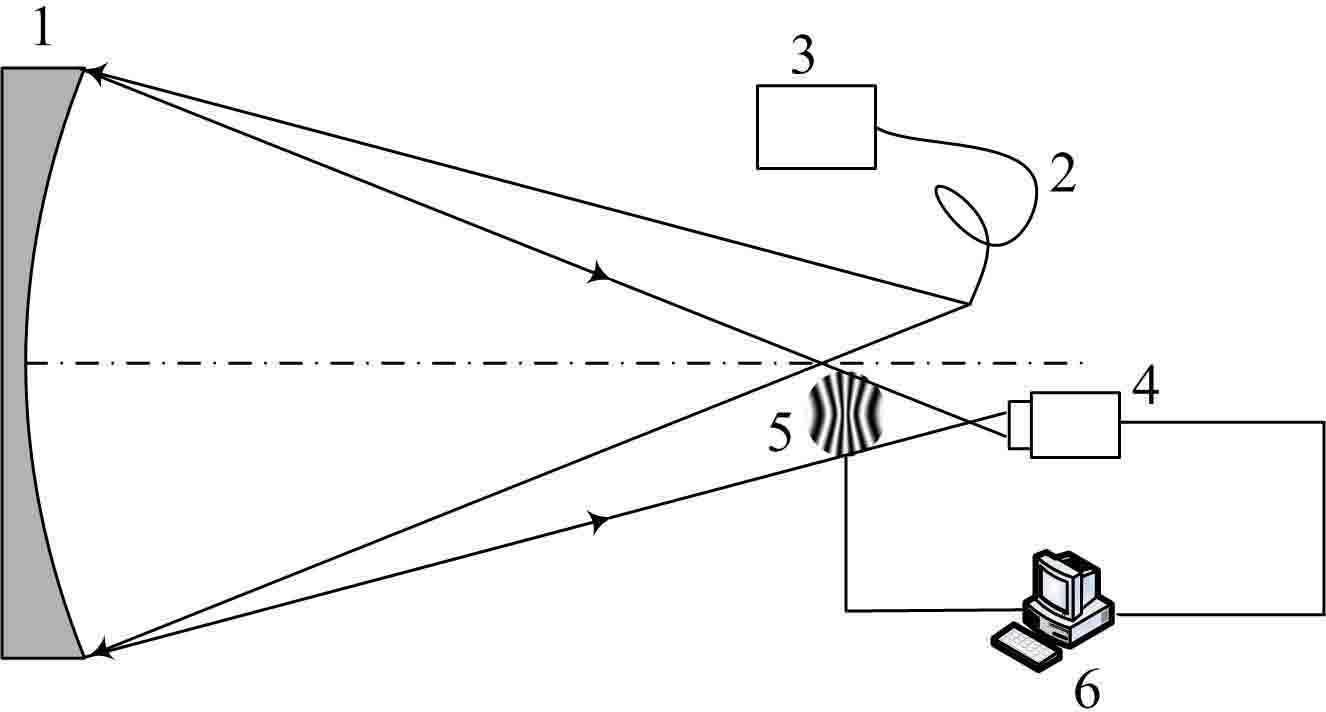

[0022] figure 1 Is the schematic diagram of the detection device, where 1 is the mirror to be tested, 2 is the optical fiber, 3 is the optical fiber lighting source, 4 is the CCD camera, 5 is the transmission liquid crystal display screen, and 6 is the computer. During detection, a compensated sinusoidal grating needs to be displayed on the transmission liquid crystal display 5 .

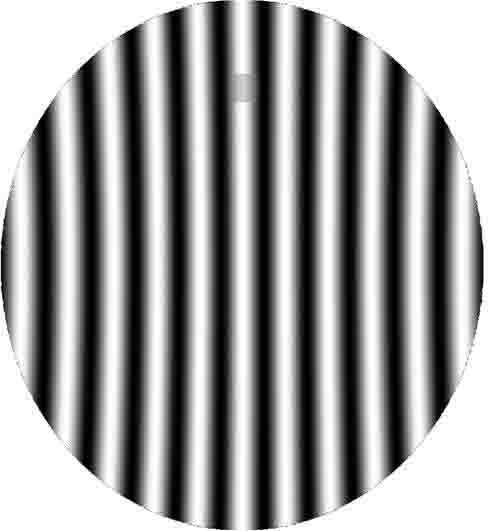

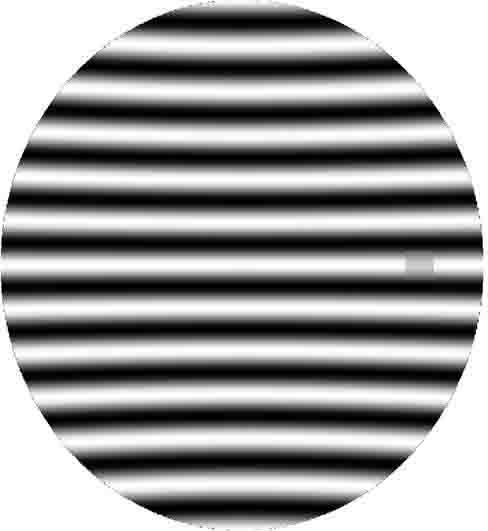

[0023] Compensated sinusoidal gratings are designed as figure 2 As shown, when designing a compensated sinusoidal grating, it is assumed that there are given straight sinusoidal fringes on the ideal surface, and the curved fringes on the compensated grating are calculated using ray tracing and the phase information of the fringes. exist figure 2 center of ideal face shape o A Cartesian coordinate system is established for the coordinate or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com