Three-dimensional visual measuring system based on high-speed triangle wave fringe projection principle

A three-dimensional vision and measurement system technology, applied in the field of three-dimensional vision measurement systems, can solve the problems of difficult calibration of defocus models and small working depth of field, and achieve the effects of improved projection time, easy timing, and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

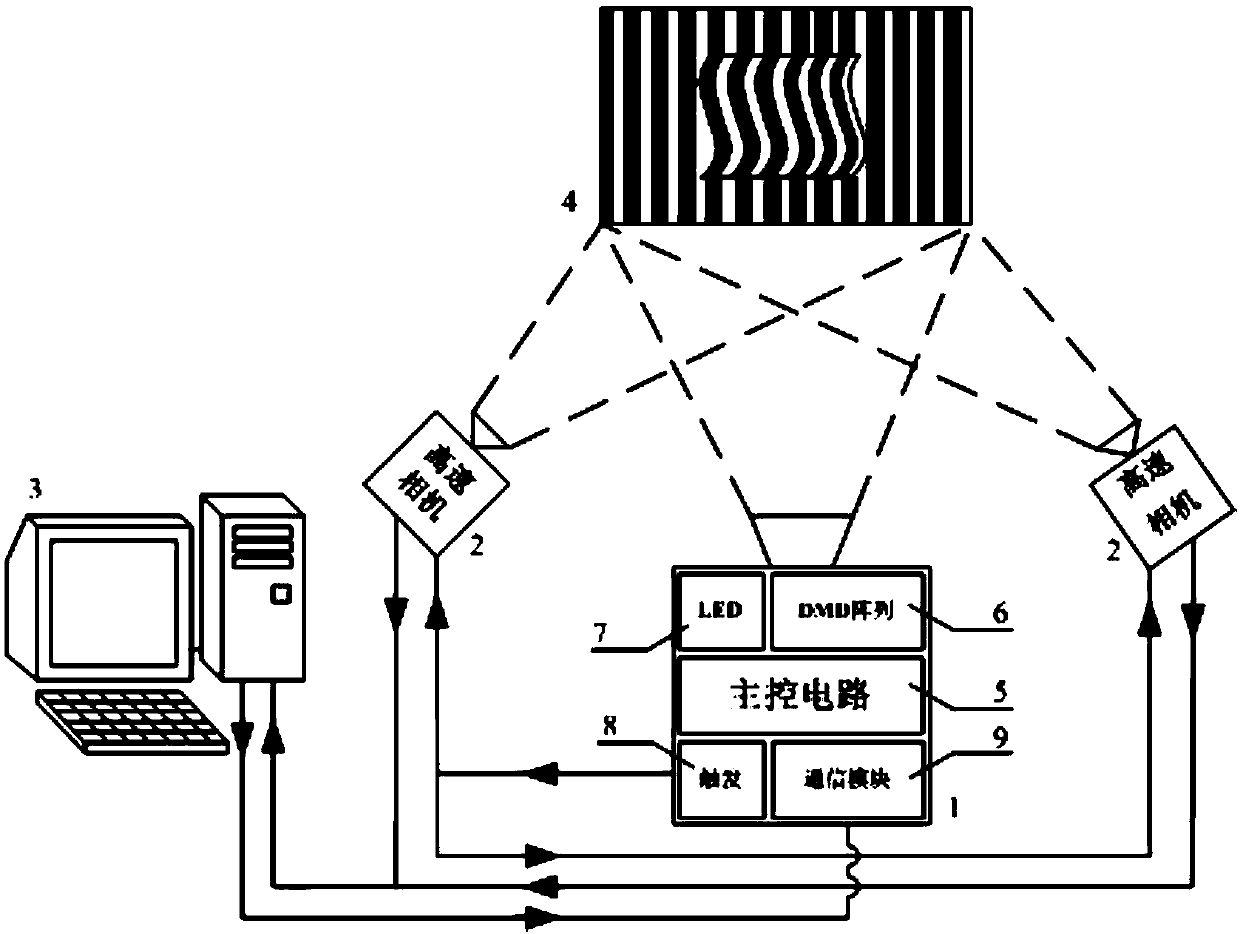

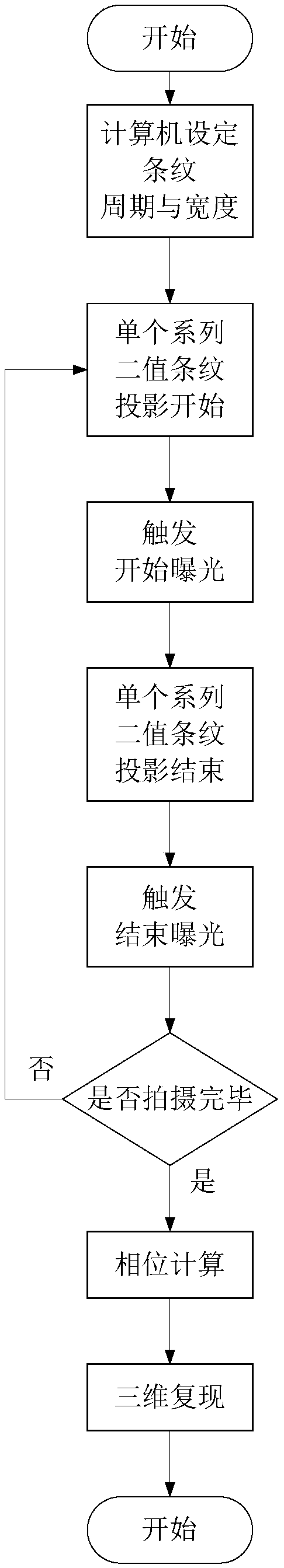

[0021] Such as figure 1 As shown, the present invention includes a DMD high-speed projector (1), two high-speed industrial cameras (2) and a computer (3). The high-speed projector (1) is composed of a main control circuit (5), a DMD projection array (6), an LED light source (7), a trigger unit (8) and a communication module (9). During work, the computer (3) transmits the structured light information to be projected to the communication module (9) of the DMD high-speed projector (1) through the USB (Universal Serial Bus architecture) interface, and the communication module transmits the data via the main control The circuit (5) is compiled into an inversion signal of the DMD projection array (6), and at the same time controls the LED light source (7) to adjust brightness. The trigger unit (8) is synchronized with the projector, triggers the high-speed camera (2) to take pictures of the measured object (4), and transmits the obtained image information to the computer (3) for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com