Scanning vibrating mirror vibration parameter measurement system and measurement method

A technology of scanning galvanometer and measurement system, which is applied in the direction of measuring device, ultrasonic/sonic wave/infrasonic wave, instrument, etc. It can solve the problems affecting the dynamic performance of galvanometer, low frequency response, small angle measurement range, etc., and achieve the measurement optical path Stable structure, strong anti-interference ability, and large angle measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

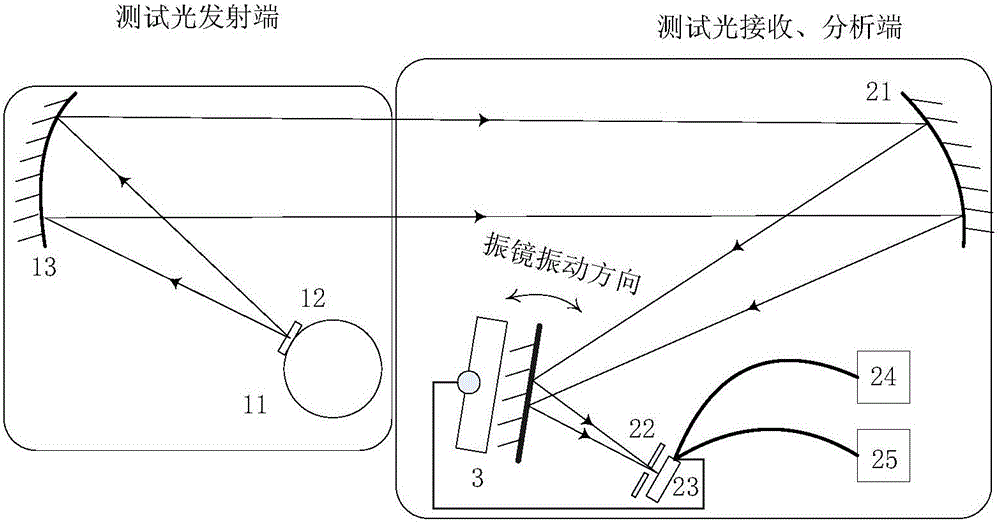

[0054] Such as figure 1 As shown, the measurement system for the vibration parameters of the scanning galvanometer provided by the present invention is composed of a measurement light emitting end, a measurement light receiving end, and an analysis end.

[0055] 1. Measuring the light emitting end

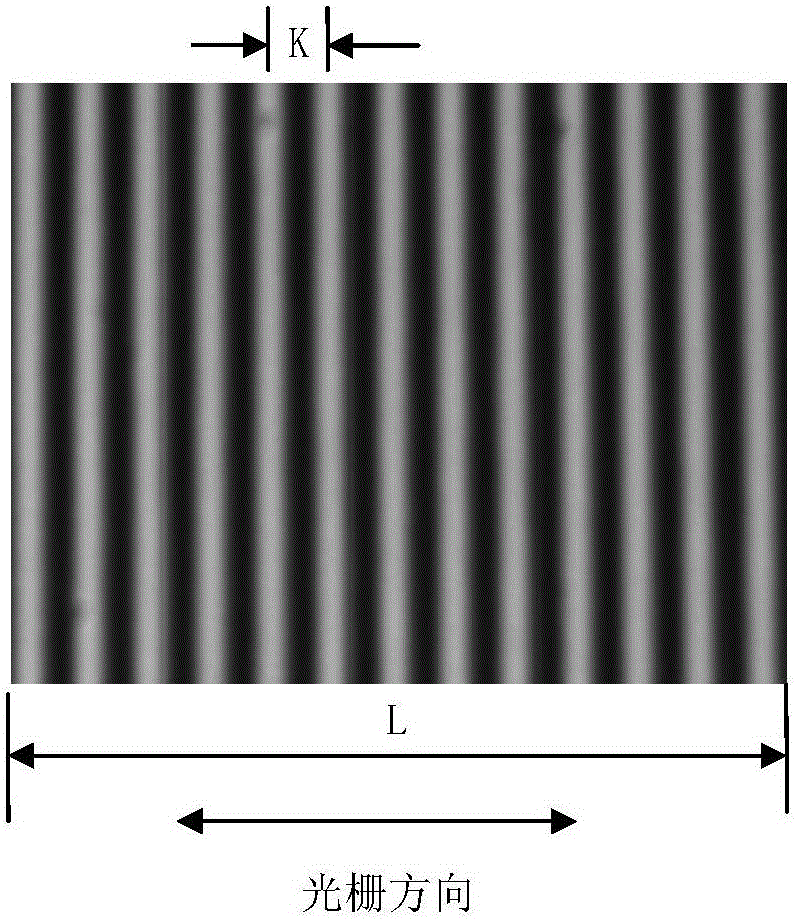

[0056]The measuring light emitting end includes an integrating sphere white light source 11 and a first off-axis parabolic reflector 13; a sinusoidal grating 12 is placed at the light outlet of the integrating sphere white light source 11, and the direction of the sinusoidal grating 12 is consistent with the vibration direction of the scanning galvanometer 3 to be measured. Parallel; the first off-axis parabolic reflector 13 is located on the outgoing light path of the integrating sphere white light source 11, and forms a collimator with the inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com