Trapezoid primitive optical grating with single-stage diffraction properties

A single-stage diffraction, trapezoidal technology, applied in the field of diffraction grating, can solve the problems of limited quantum lattice grating, low absolute diffraction efficiency, and difficult processing, etc., and achieve the effect of high diffraction efficiency and convenient design and manufacture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0023] According to the actual application, determine the period size of the grating;

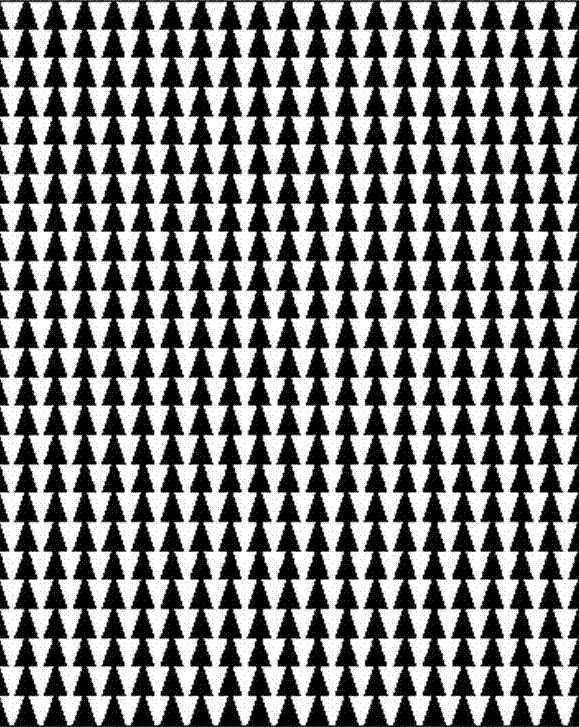

[0024] The trapezoidal primitives are stacked sequentially along the one-dimensional direction of the grating base; the other dimension along the grating base is copied according to the length of the grating period, such as figure 1 as shown, figure 1 The horizontal direction of is the periodic direction of the grating, and the vertical direction is the other one-dimensional direction of the grating;

[0025] The trapezoidal primitive of the grating is an isosceles trapezoid, and its upper and lower bases are related to the period d of the grating, which are d / 6 and 5d / 6 respectively, and the height of the trapezoid is designed to be d;

[0026] The base of the trapezoidal primitive grating is a transparent substrate;

[0027] The trapezoidal primitive of the grating is the high reflectivity material coated on the transparent substrate or the small gap between the high reflectivity materi...

Embodiment 1

[0030] This embodiment discloses a planar transmissive trapezoidal primitive grating designed based on the present invention. The trapezoidal primitive grating is shown in figure 1 ,include:

[0031] 1) Transparent silicon carbide substrate;

[0032] 2) Form multiple high-reflectivity trapezoidal primitive ring structures with two-dimensional distribution on a transparent substrate;

[0033] 3) Fabricate planar transmissive trapezoidal primitive gratings by micromachining techniques such as photolithography and electron beam etching.

[0034] figure 1 The part composed of white trapezoidal primitives is a material coated with high reflectivity; the black part is a fully transparent substrate.

[0035] The unique structure of the planar transmissive trapezoidal primitive grating designed based on the invention makes the designed and manufactured grating have single-order diffraction characteristics and high diffraction efficiency characteristics.

[0036] This example has o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com