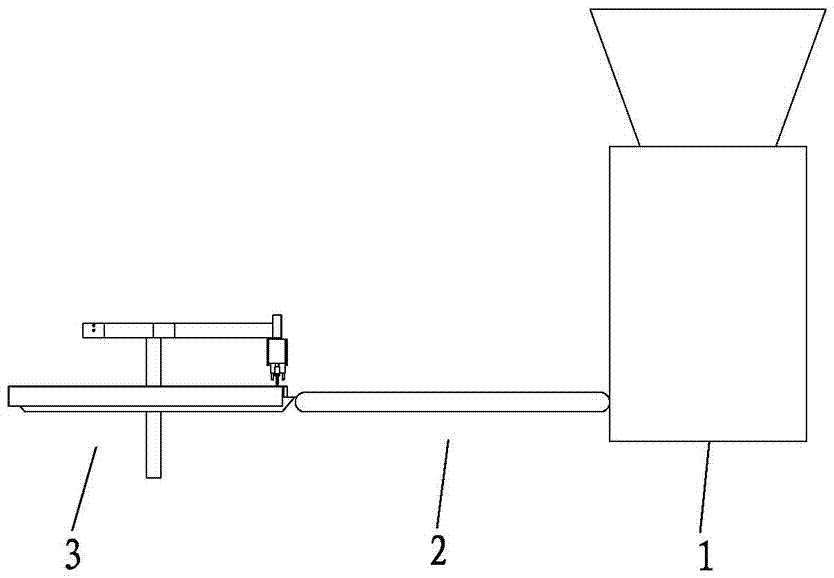

Full automation gold ingot shape Ravioli forming device and all-in-one machine

A molding device, fully automatic technology, applied in baking, dough processing, food science and other directions, can solve the problem of lack of molding device, save labor and production cost, increase production efficiency, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

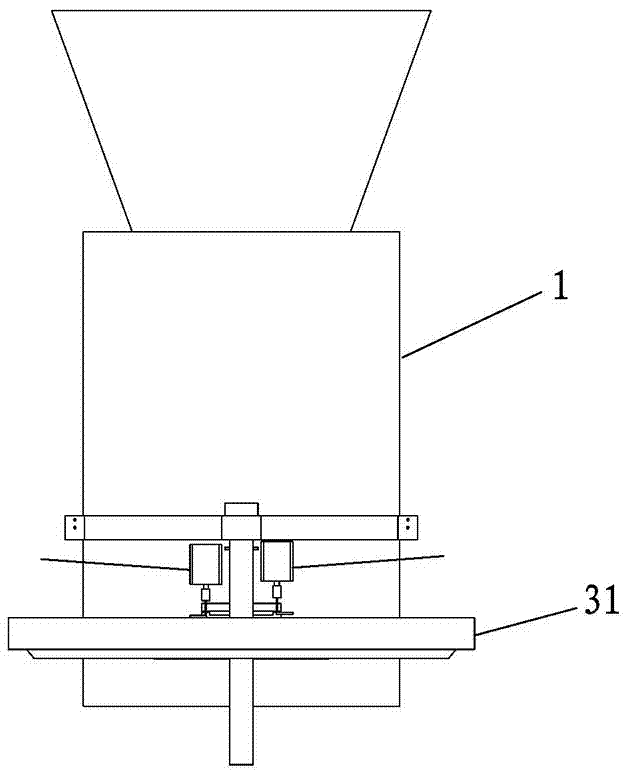

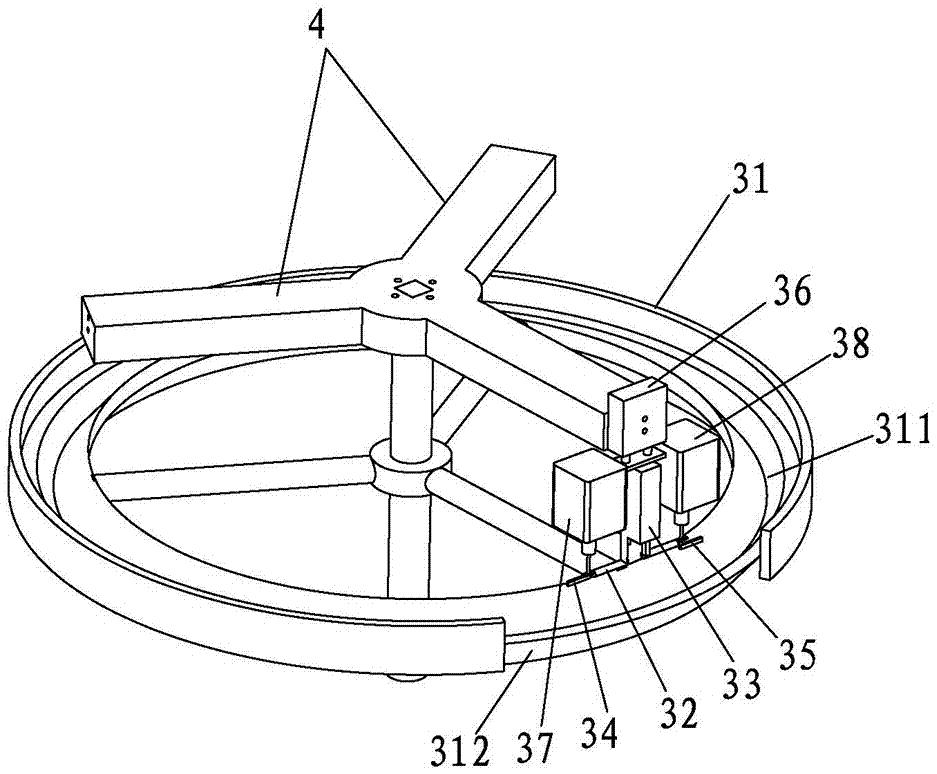

[0030] The present case will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0031] This case involves a fully automatic ingot-shaped wonton forming device, such as Figure 3-5 Shown, comprise rotating disc 31 and forming mechanism. A sunken groove 311 is formed in the turntable 31 , and the molding mechanism is arranged above the sunken groove 311 . The forming mechanism mainly includes a push rod 32 , an air gripper 33 , a left swing rod 34 and a right swing rod 35 . Both the push rod 32 and the air claw 33 are located between the left swing link 34 and the right swing link 35 .

[0032] The ejector rod 32 is located directly above the sinking tank 311, and it is connected with a lifting drive unit that drives it to lift. A preferred embodiment of the lifting drive unit is a lifting cylinder 36, and the ejector rod 32 is connected to the piston shaft of the lifting cylinder 36, here By means of the up-and-down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com