Manufacturing method of artificial dielectric multilayer cylindrical lens

A lenticular lens and manufacturing method technology, applied to electrical components, antennas, etc., can solve problems such as complex processing and heavy weight, and achieve the effects of simple manufacturing process, wide coverage, and precise manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

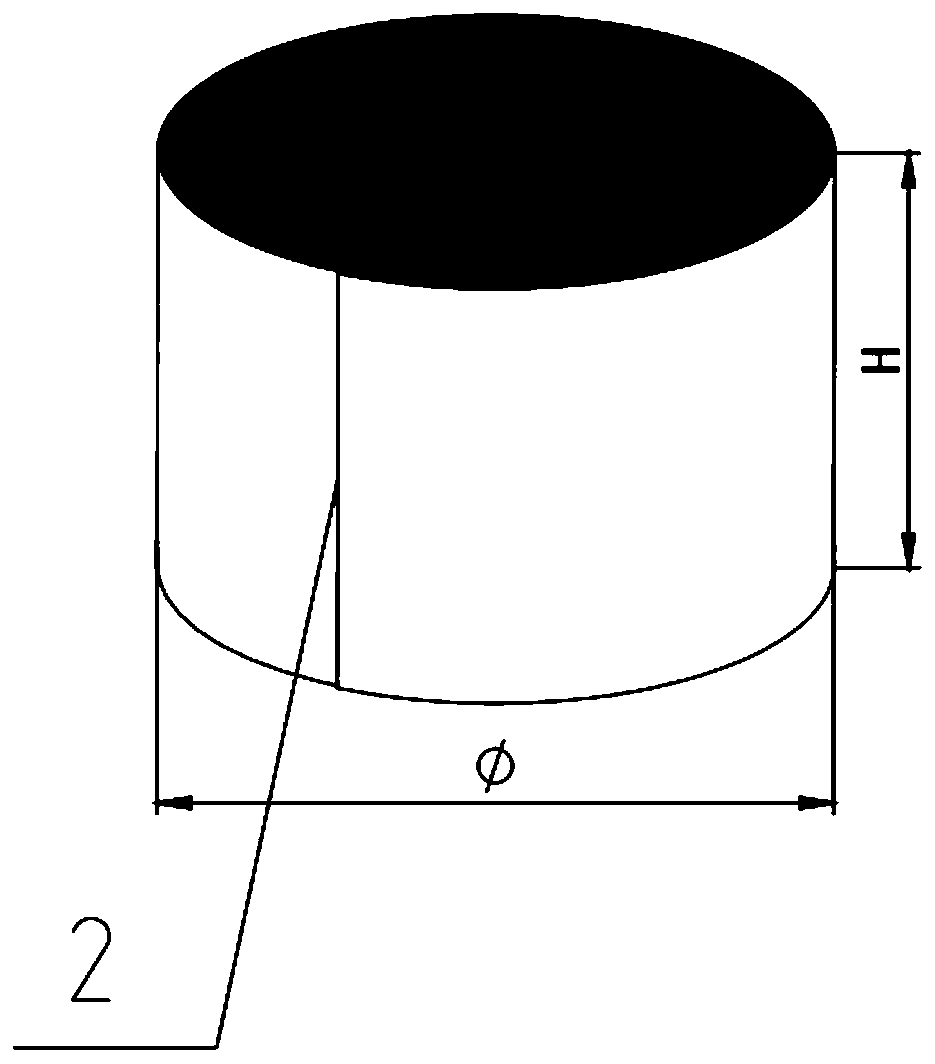

[0083] Embodiment 1: the preparation method of cylindrical lens

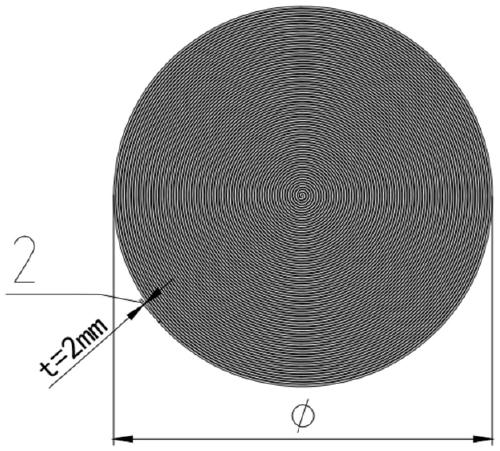

[0084] S1: Select single-sided adhesive foam with a thickness t of 2mm as the base material 2;

[0085] S2: Lay the base material described in step S1 on the workbench, with the glue side up, and divide the base material with the glue side up into n regions, and spread out along the length direction;

[0086] S3: Sprinkle the designed m kinds of high dielectric constant granular materials according to the dielectric constant in order from large to small in the n areas where the collodion faces upward in step S2, where m=n, m and n are both greater than 1 an integer of

[0087] Wherein, the dielectric constant of the high dielectric constant granular material designed in this embodiment is different; wherein, the different types of the dielectric constant of the high dielectric constant granular material in this embodiment are the same as the divided regions of the substrate;

[0088] S4: the base material of a...

Embodiment 2

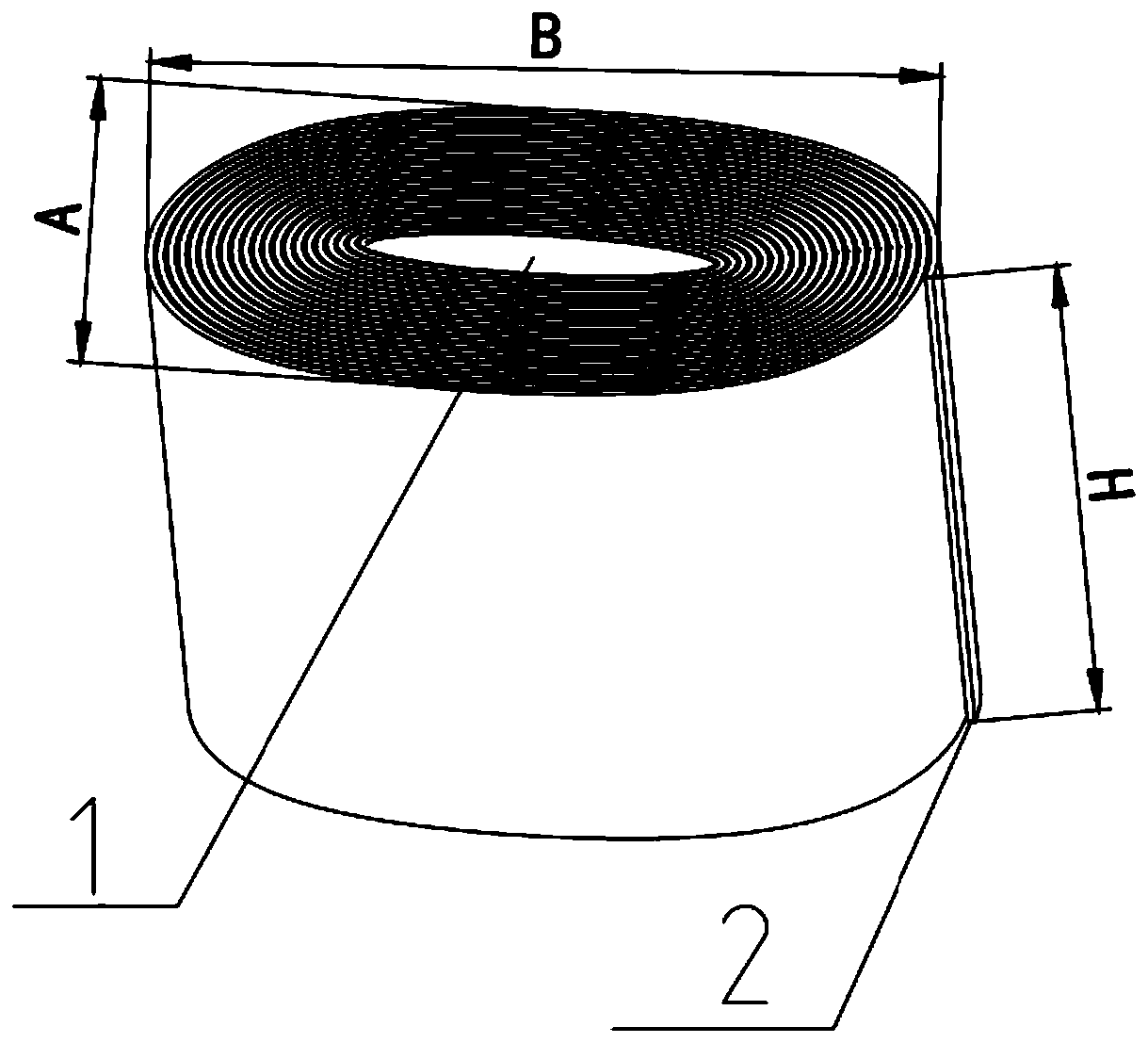

[0093] Embodiment 2: the preparation method of elliptic cylinder lens

[0094] This embodiment provides a method for manufacturing an artificial medium multilayer elliptical cylindrical lens, comprising the following steps:

[0095] S11: Select a single-sided adhesive foam with a thickness t of 2mm as the base material 2;

[0096] S12: Lay the base material described in step S11 on the workbench, with the glue side up, and divide the base material with the glue side up into n regions, and expand along the length direction;

[0097] S13: Sprinkle the designed m kinds of high dielectric constant granular materials evenly in order according to the dielectric constant from large to small in the n regions of the substrate with the adhesive surface facing up in step S12; among them, the designed in this embodiment The dielectric constants of high dielectric constant granular materials are different; wherein, m=n, m and n are both integers greater than 1.

[0098] S14: Roll and pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com