Lithium metal alloy negative electrode material and preparation method and application thereof

A technology of alloy negative electrode and negative electrode material, which is applied in the direction of battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of expensive nano-processing methods and complex preparation processes, and achieve rapid mass production, ensure cycle performance, and low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] This example is used to illustrate the preparation process of the metal lithium alloy negative electrode of the present invention.

[0057] (1) Weigh 0.7g metal lithium sheet and 0.28g monocrystalline silicon sheet, and place them in a container that does not react with lithium and silicon in a glove box filled with argon;

[0058] (2) Heating the container to 200°C, the metal lithium is completely melted, and contacts with silicon for an alloying reaction; stir the liquid alloy for 30 minutes to make it evenly mixed;

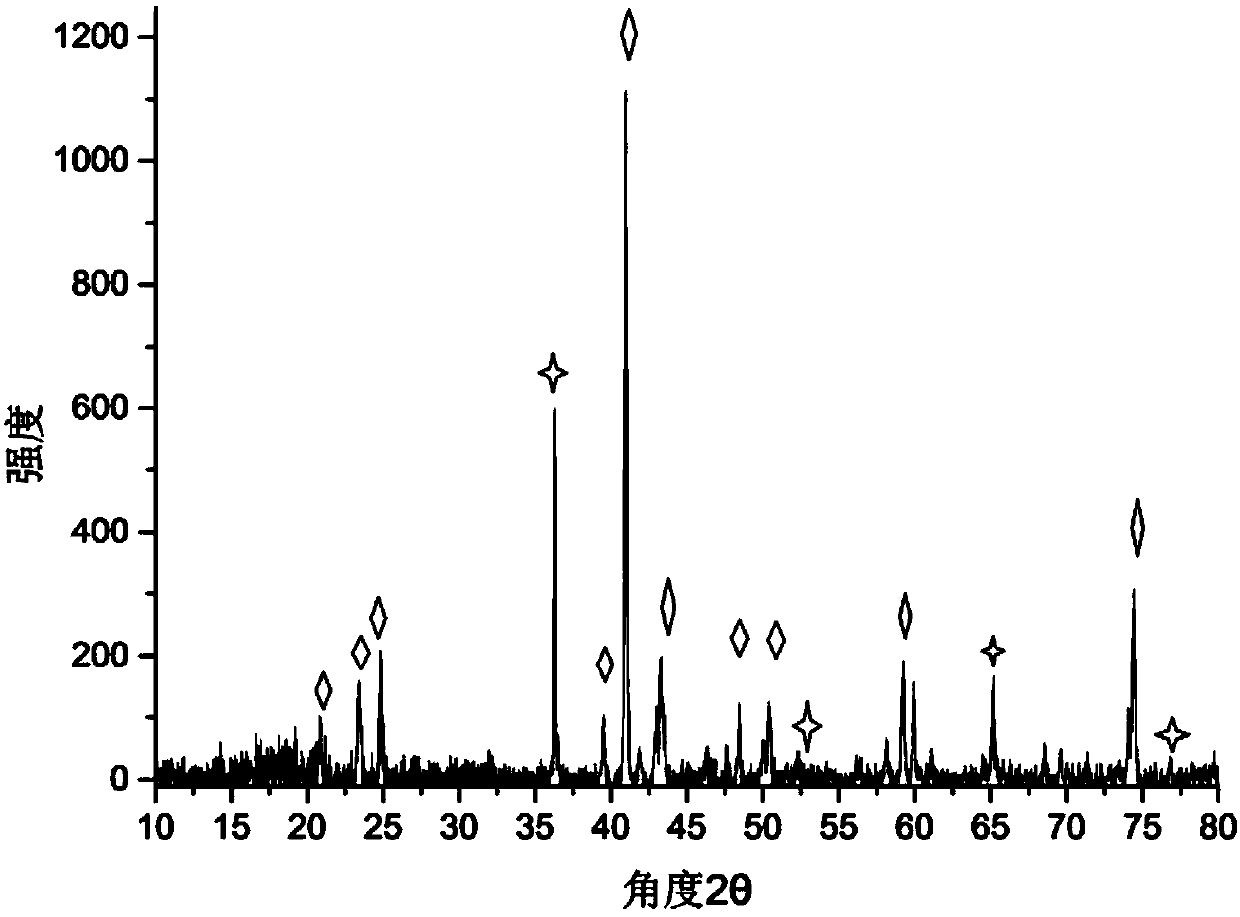

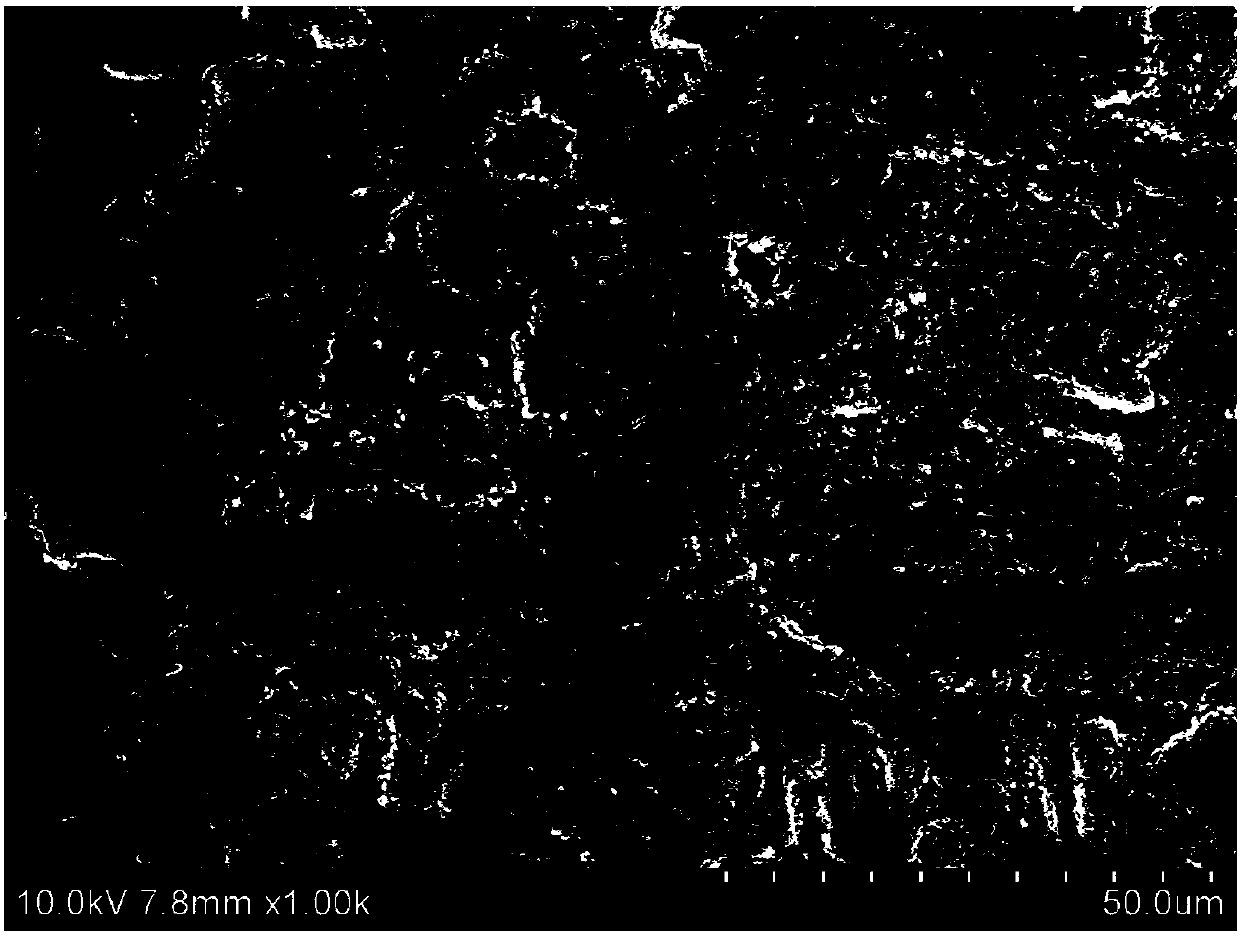

[0059] (3) Coating the mixture onto an iron foil current collector with a thickness of 100 μm; cooling down to room temperature at a rate of 80°C / s to obtain lithium metal and lithium-silicon alloy (Li 58 +Li 22 Si 5 ) negative pole, denoted as A1.

Embodiment 2

[0061] The negative electrode is prepared in the same manner as in Example 1, except that, in step (1), 0.28g of nano-silicon powder is used to replace 0.28g of single-crystal silicon sheet to obtain lithium metal and lithium-silicon alloy (Li 58 +Li 22 Si 5 ) negative pole, denoted as A2.

Embodiment 3

[0063] The negative electrode is prepared in the same manner as in Example 1, the difference is that in step (1), 1.12g of tin powder is used to replace 0.28g of a single crystal silicon chip to obtain a metal lithium and lithium-tin alloy (Li 58 +Li 17 sn 4 ) negative pole, denoted as A3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com