Silk nanofiber manufacturing method

A nanofiber and silk technology, applied in silk fiber production, chemical post-processing of fibers, fiber treatment, etc., can solve the problems of destroying silk structure and affecting subsequent use, and achieves the effect of simple equipment, easy control, and shortening of preparation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] A preparation method of silk nanofibers. The preparation method refers to transferring the degummed silk to a solution composed of small molecular compounds, deionized water, and alcohol, and soaking to weaken the binding force between nanofibrils in the silk Then, the solution soaked with the silk is transferred to a crusher, and the soaked silk is mechanically crushed to obtain the silk nanofibers. The preparation method is carried out as follows:

[0020] a Take the degummed silk and wash it with deionized water and dry it at 20~30℃;

[0021] b. Add the degummed silk dried in step a to a solution composed of small molecule compounds and deionized water in a mass ratio of 0:1 to 1:200, and alcohols to deionized water in a mass ratio of 0:1 to 1:200 Soak in medium for 3~7h to swell the silk to weaken the binding force between the nanofibrils in the silk. The mass ratio of the solution to the degummed silk is 2000:1~1000:1;

[0022] c Transfer the solution with degumm...

Embodiment 1

[0031] a Take 1g of degummed silk and wash it with deionized water, then dry the washed silk at 30°C;

[0032] b. Add the degummed silk dried in step a to a solution consisting of 9.9g of calcium chloride, 1980.2g of ionized water, and 9.9g of ethanol and soak for 7 hours to weaken the binding force between nanofibrils in the silk;

[0033] c Transfer the solution with degummed silk treated in step b to a homogenizer for mechanical crushing for 4 hours;

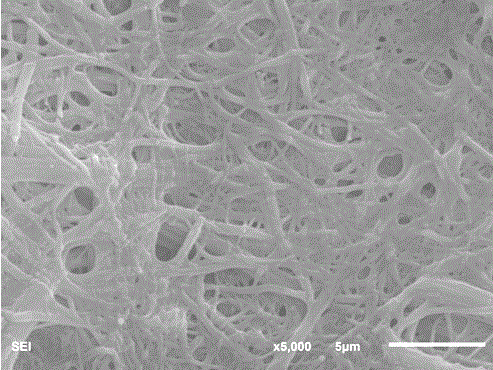

[0034] d The solution after step c is separated by centrifugation or filtration to collect the product, and then the collected product is washed with deionized water, and the obtained silk nanofiber is dried at 20°C. As attached figure 1 Shown, attached figure 1 A scanning electron microscope image of the obtained silk nanofibers magnified 5000 times. The silk nanofibers have a diameter of 50-150nm and a length of 100nm-100μm, and the nanofibers are interlaced to form a network structure.

Embodiment 2

[0036] a Take 1g of degummed silk, wash it with deionized water, and dry it at 25°C;

[0037] b. Add the degummed silk dried in step a to a solution consisting of 1g calcium sulfate, 1492.6g ionized water, and 6.4g ethanol to soak for 5 hours to weaken the binding force between nanofibrils in the silk;

[0038] c Transfer the solution with degummed silk treated in step b to an emulsifier for mechanical crushing for 6 hours;

[0039] d The solution after step c is separated by centrifugation or filtration to collect the product, and then the collected product is washed with deionized water, and the obtained silk nanofiber is dried at 20°C. The obtained silk nanofiber has a diameter of 50-150nm and a length of 100nm-100μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com