Membrane electrode pressing mould and its operation method

A technology of pressing molds and membrane electrodes, which is applied to battery electrodes, circuits, fuel cells, etc., can solve the problems of high cost, complex structure, deformation of electrolyte membrane, etc., avoid damage and pollution, simple mold structure, and prevent splashing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

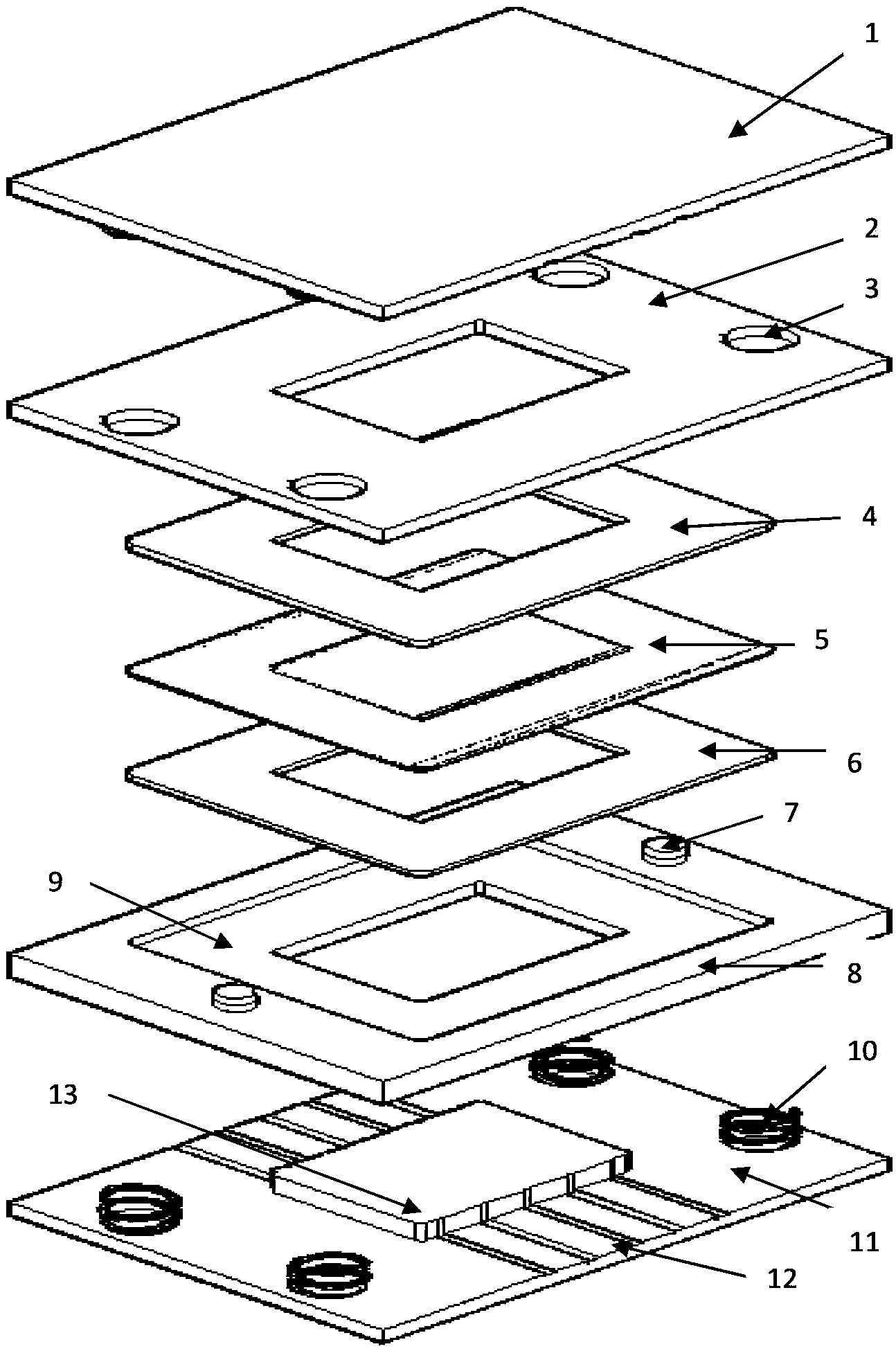

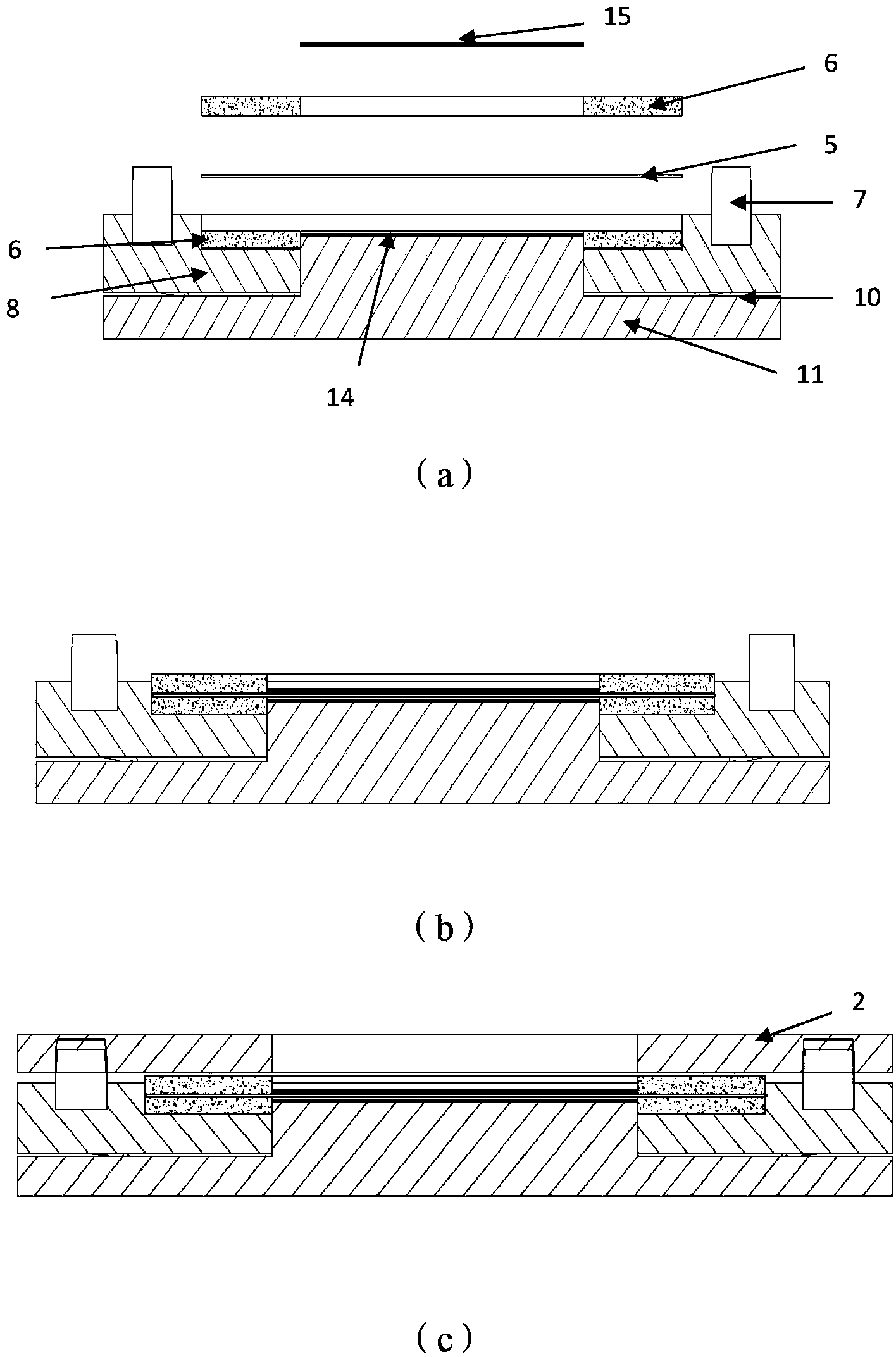

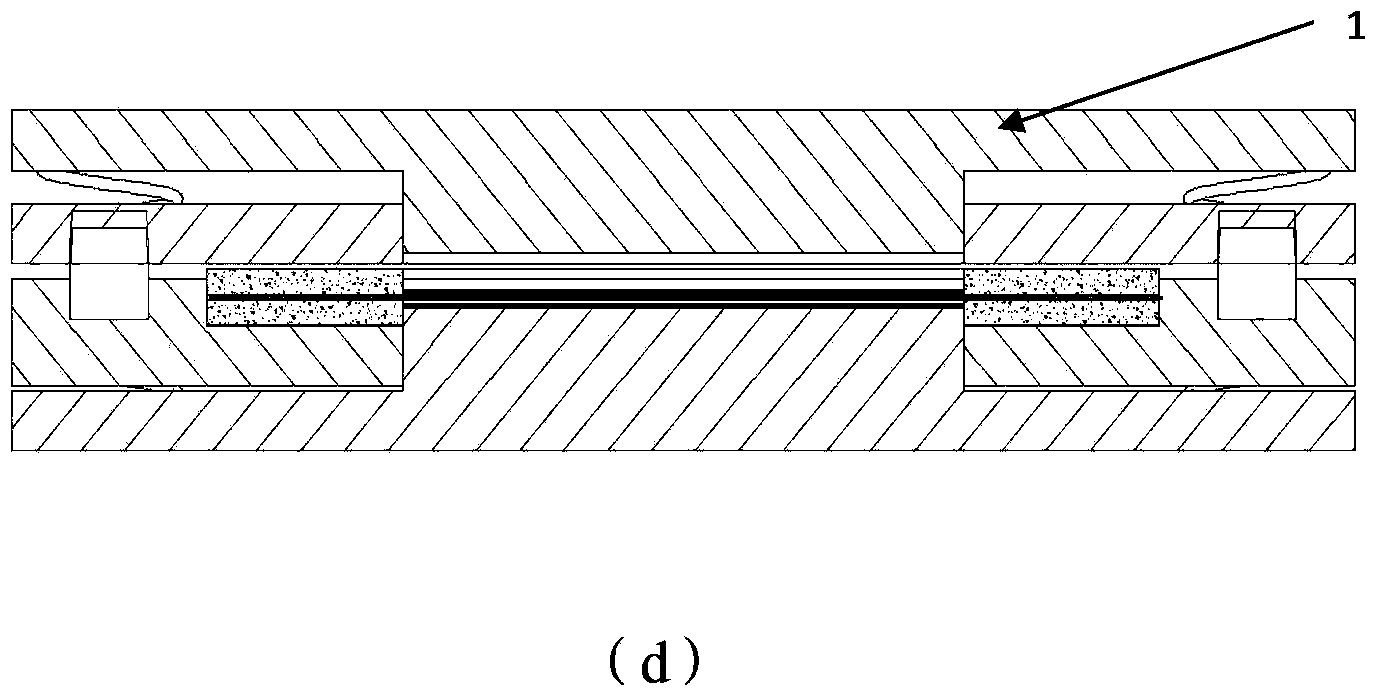

[0032] The Membrane Electrode Pressing Die includes an upper pressing plate 1 , an upper positioning plate 2 , an upper positioning cushion 4 , a lower positioning cushion 6 , a lower positioning plate 8 and a lower pressing plate 11 . Among them, the upper and lower pressure plates have the same structure, and there is a square pressing boss 13 with the same shape as the diffusion layer of the membrane electrode; the exhaust flow channel 12 for discharging water vapor during hot pressing; the pressure transmission and the pressing of the upper and lower positioning plates Spring 10, the depth of the exhaust flow path is between 0.05 ~ 2mm, and the compression spring is fixed by the positioning groove on it. The structure of the upper positioning plate 2 is slightly different from that of the lower positioning plate 8. Both the upper and lower positioning plates have square positioning holes and spring positioning grooves 3 with the same shape as the diffusion layer of the memb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com