Wearable multifunctional flexible sensor and manufacturing method thereof

A flexible sensor and multi-functional technology, applied in the direction of instruments, measuring devices, material resistance, etc., can solve problems such as pollution, inability to guarantee flexibility, high cost, etc., and achieve the effect of wide application prospects, good product performance, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

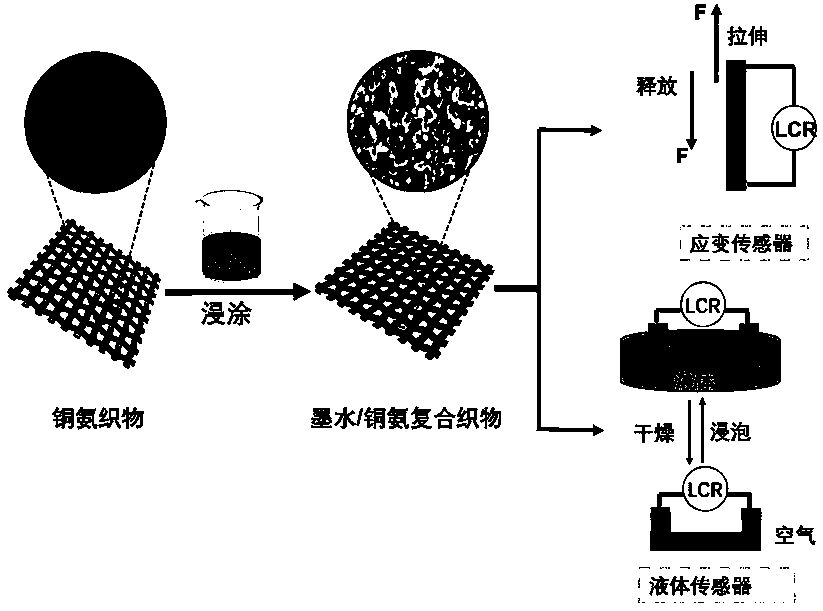

[0032] (1) Evenly mix graphite, sulfuric acid, oxalic acid and glycerol at a mass ratio of 5:1:1:1;

[0033] (2) Mix the mixture obtained in step (1) with deionized water at a mass ratio of 1:5 and stir evenly at room temperature at a rate of 1000 rpm to obtain carbon ink, and place it in a refrigerator at 2°C Refrigerate for 24 hours;

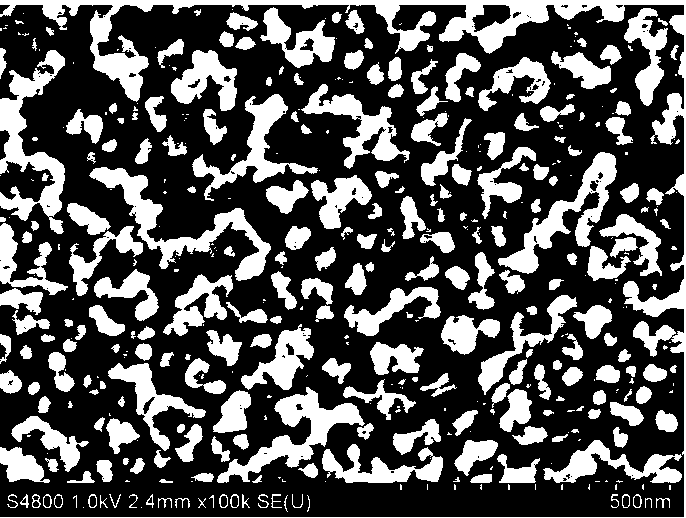

[0034] (3) Soak the cupro ammonia fabric cleaned 3 times by ultrasonic in the carbon ink in step (2) for 5 minutes, take it out and dry it in an oven at 120°C for 10 minutes;

[0035] (4) Repeat step (3) 5 times, and the deposition amount of different inks is 4.68 mg cm -2 layer of inductive conductive material;

[0036] (5) The two ends of the obtained sensing conductive layer are connected by conductive silver glue and leads are drawn out to form a multi-functional flexible sensor.

[0037] The strain sensing performance and liquid sensing performance of the prepared multifunctional flexible sensor were tested respectively, and it was fou...

Embodiment 2

[0039] (1) Evenly mix graphite, sulfuric acid, oxalic acid and glycerol at a mass ratio of 5:2:2:2;

[0040] (2) Mix the mixture obtained in step (1) with deionized water at a mass ratio of 1:10 and stir evenly at room temperature at a rate of 1000 rpm to obtain carbon ink, and place it in a refrigerator at 2°C Refrigerate for 24 hours;

[0041] (3) Soak the cupro ammonia fabric cleaned 3 times by ultrasonic in the carbon ink in step 2) for 5 minutes, then take it out and place it in an oven at 120°C for 5 minutes;

[0042](4) Repeat step (3) 3 times, and the deposition amount of different inks is 2.32 mg cm -2 layer of inductive conductive material;

[0043] (5) The two ends of the obtained sensing conductive layer are connected by conductive silver glue and leads are drawn out to form a multi-functional flexible sensor.

[0044] The strain sensing performance and liquid sensing performance of the prepared multifunctional flexible sensor were tested respectively, and it wa...

Embodiment 3

[0046] (1) Evenly mix graphite, sulfuric acid, oxalic acid and glycerol at a mass ratio of 5:2:3:3;

[0047] (2) Mix the mixture obtained in step (1) with deionized water at a mass ratio of 1:15 and stir evenly at room temperature at a rate of 1000 rpm to obtain carbon ink, and place it in a refrigerator at 4°C Refrigerate for 48 hours;

[0048] (3) Soak the Tencel fabric cleaned twice by ultrasonic waves in the carbon ink in step (2) for 5 minutes, then take it out and dry it in an oven at 130°C for 5 minutes;

[0049] (4) Repeat step (3) once, and the deposition amount of different inks is 1.26 mg cm -2 layer of inductive conductive material;

[0050] (5) The two ends of the obtained sensing conductive layer are connected by conductive silver glue and leads are drawn out to form a multi-functional flexible sensor.

[0051] The strain sensing performance and liquid sensing performance of the prepared multifunctional flexible sensor were tested respectively. It was found th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com