Preparation method of beta-nano-SiC

A nano-silicon carbide and carbon-silicon technology, applied in chemical instruments and methods, carbon compounds, nanotechnology, etc., to achieve the effects of simple equipment, low production cost, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

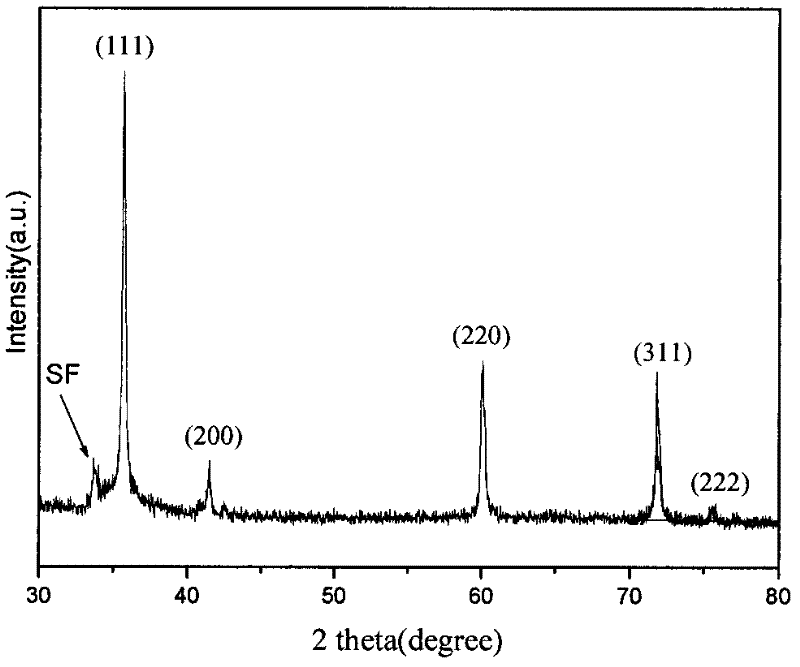

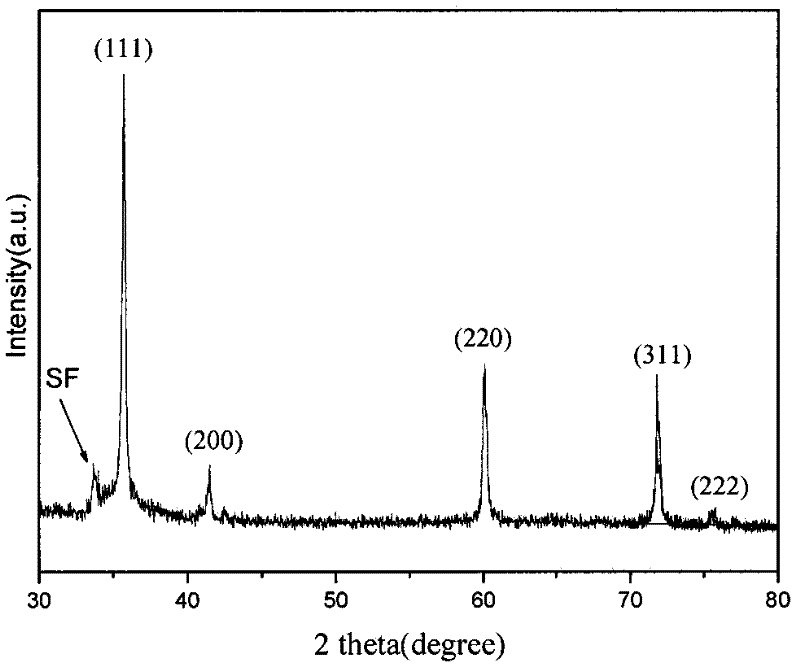

Image

Examples

Embodiment 1

[0018] 1. Weigh 10 grams of starch and mix with 11 grams of industrial water glass, stir evenly, let stand for 5 minutes, and then dry at 70°C for 12 hours.

[0019] 2. Put the dried product into a tube-type high-temperature furnace, pass in argon gas, raise the temperature to 1200°C, and react at constant temperature for 10 hours, then cool it naturally to room temperature under an argon gas atmosphere.

[0020] 3. The obtained reaction product was oxidized in air at 700°C for 3 hours, then soaked in a mixed acid of hydrochloric acid and hydrofluoric acid with a volume ratio of 1:1.5 for 12 hours, and finally washed, filtered, and dried to obtain a product with a diameter of 3-50nm. , β-silicon carbide nanofibers with micron-scale lengths.

Embodiment 2

[0022] 1. Weigh 15 grams of sucrose and mix it with 30 grams of industrial water glass, stir well and let stand for 15 minutes, then dry at 90°C for 10 hours.

[0023] 2. Put the dried product into a tube-type high-temperature furnace, pass in argon gas, raise the temperature to 1300°C, and react at constant temperature for 6 hours, then cool it naturally to room temperature under an argon gas atmosphere.

[0024] 3. The obtained reaction product was oxidized in air at 600°C for 5 hours, then soaked in a mixed acid of hydrochloric acid and hydrofluoric acid with a volume ratio of 1:2 for 15 hours, and finally washed, filtered, and dried to obtain a product with a diameter of 10-90nm. , β-silicon carbide nanowires with micron-scale lengths.

Embodiment 3

[0026] 1. Weigh 25 grams of starch and mix it with 100 grams of industrial water glass, stir well and let stand for 25 minutes, then dry at 110°C for 9 hours.

[0027] 2. Put the dried product into a tube-type high-temperature furnace, pass in argon gas, raise the temperature to 1330°C, and react at constant temperature for 7 hours, then cool naturally to room temperature under an argon gas atmosphere.

[0028] 3. The obtained reaction product was oxidized in air at 800°C for 2 hours, then soaked in a mixed acid of hydrochloric acid and hydrofluoric acid with a volume ratio of 1:3 for 24 hours, and finally washed, filtered, and dried to obtain a product with a diameter of 20-200nm. , β-silicon carbide nanowires with micron-scale lengths.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com