Converter unit

A converter and ultrasonic transducer technology, applied in non-electric welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of high mechanical load heating effect energy loss, transmission elements not prevailing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

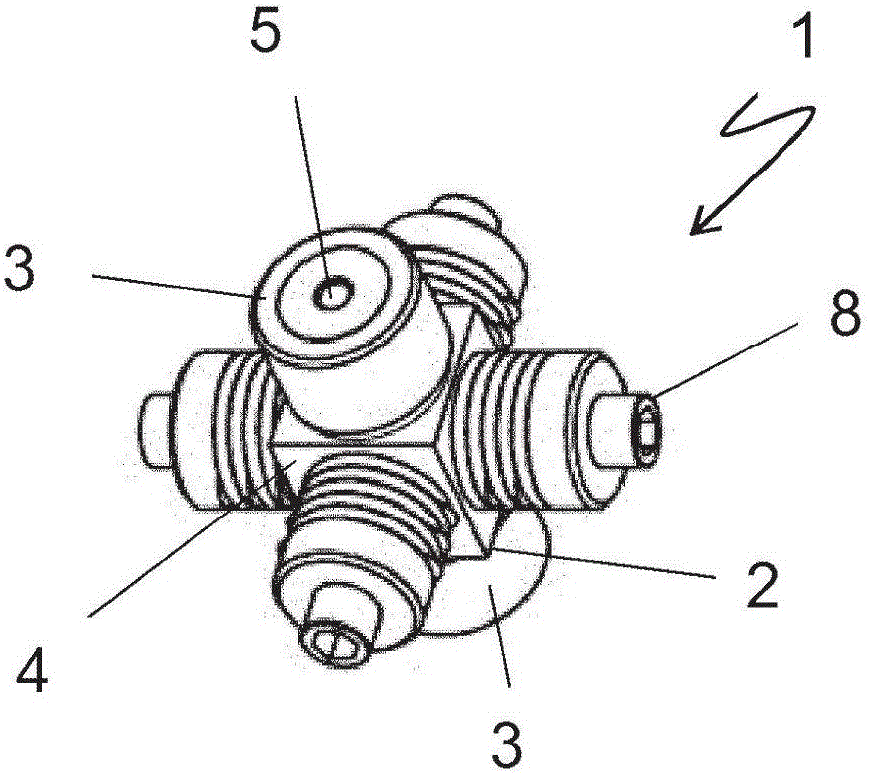

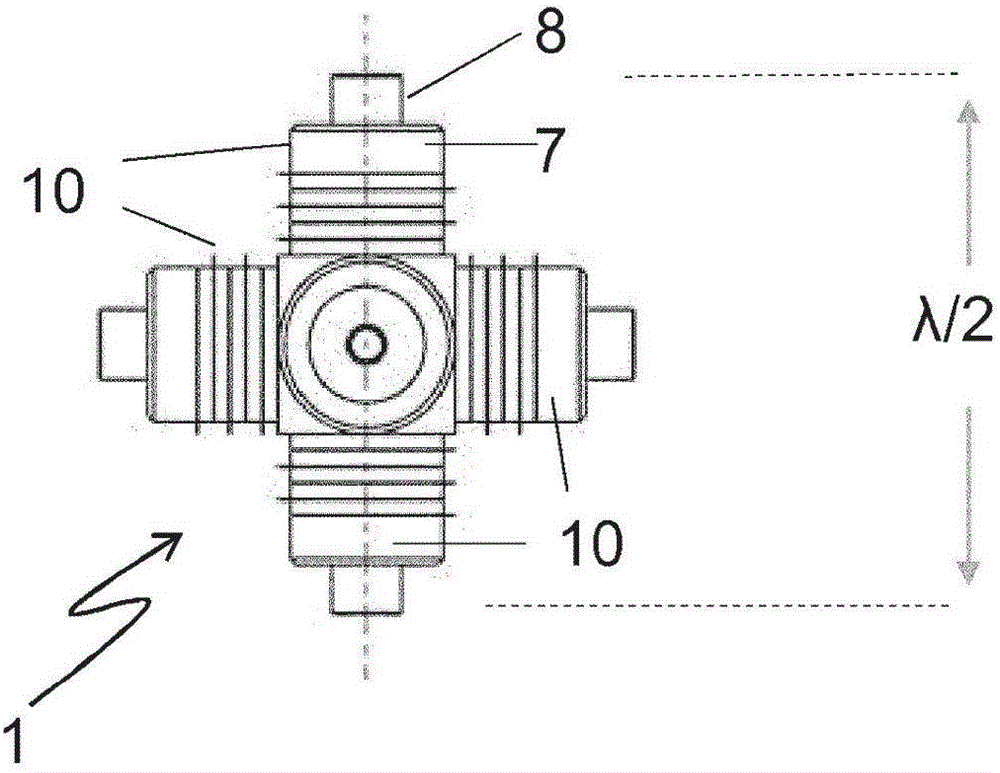

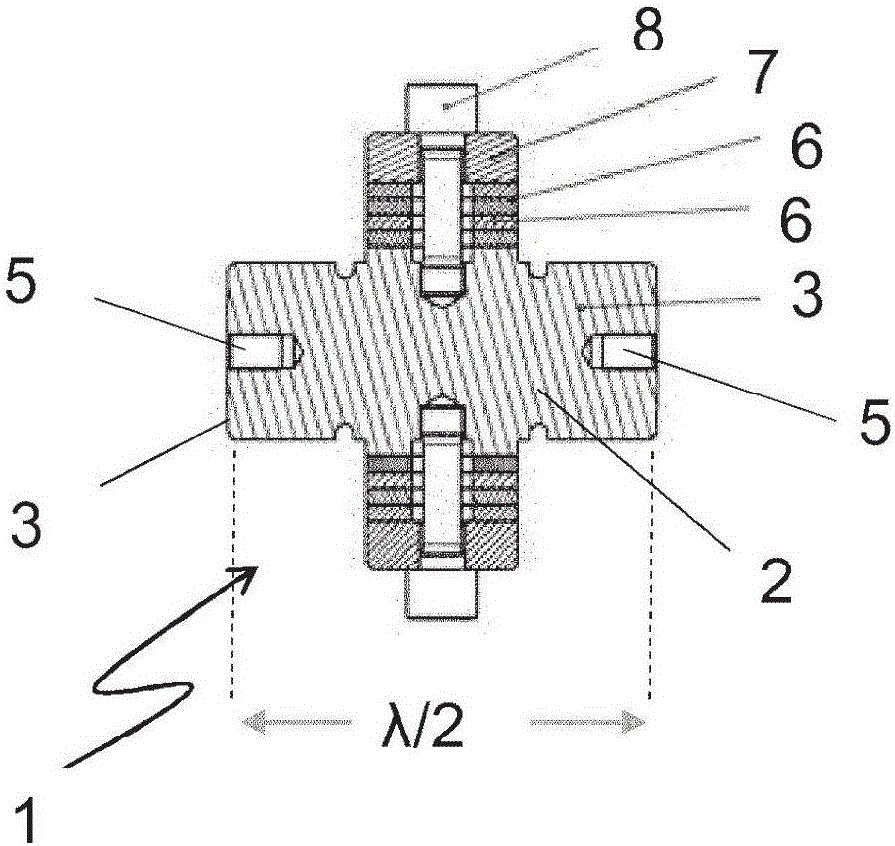

[0039] Figures 1 to 3 Various views of a converter unit 1 according to the invention are shown. The transducer unit 1 has an ultrasound transmission element 2 comprising a cuboidal base part 4 and two arms 3 extending in the longitudinal direction. The longitudinally extending arm 3 is of cylindrical configuration and has a corresponding threaded hole 5 on its end face for fastening a tool such as a welding electrode. The ultrasonic transmission element 2 is subjected to longitudinal ultrasonic vibrations at least on the end face, on which the tool to be excited is fixed. Thus, in the case of resonance, the maximum value of the vibration is formed at the end face, and the vibration node of the longitudinal vibration is generated at the center point of the ultrasonic transmission element 2 .

[0040] Figure 4A perspective view of the ultrasound transmission element 2 is shown. Two longitudinal arms 3 are visible extending from the cuboidal body, and one of them has a tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com