Method for preparing vacuum insulated panel core materials by using glass fiber aggregation leftover material and vacuum insulated panel

A vacuum insulation panel and glass fiber technology, which is applied in mechanical equipment, heat exchange equipment, and pipelines through thermal insulation protection, etc., can solve problems such as unfavorable production and use, and achieve lower material costs, lower production costs, and small expansion rates. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1 Preparation of insulation board core material by using glass fiber aggregate scrap

[0025] (1) choosing fiber diameter is 3.5 μ m, and average length is the leftover material of centrifugal glass wool fiber aggregate of 5 mm;

[0026] (2) Utilize the fiber cutting machine to cut and disperse the fiber aggregates;

[0027] (3) Pave the cut and dispersed fibers into the mold through the distributor;

[0028] (4) Heat the laid glass fibers to 600°C and press them into shape under a pressure of 0.5MPa.

[0029] After rapid cooling, a dry-process glass fiber core material with good mechanical strength and no rebound is obtained.

[0030] Fabrication of vacuum insulation panels

[0031] (1) Make a three-side sealed gas barrier bag, the structure of the gas barrier film is:

[0032] PET12 / vmPET12 / vmPET12 / LDPE50, where PET12 refers to a polyethylene terephthalate film with a thickness of 12 μm, and vmPET12 refers to a polyethylene terephthalate film with a thickn...

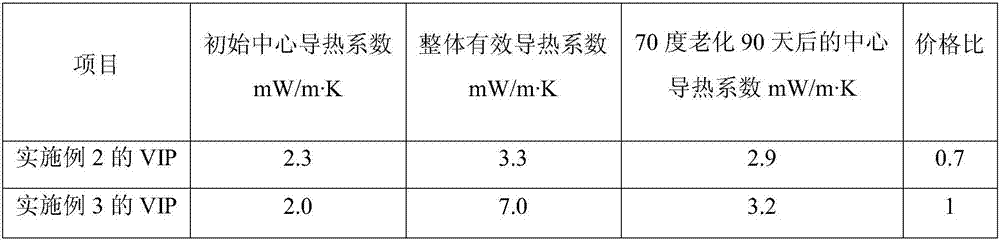

Embodiment 2

[0035] Example 2 Preparation of insulation board core material by using glass fiber aggregate scrap

[0036] (1) choosing fiber diameter is 2 μ m, and average length is the leftover material of centrifugal glass wool fiber aggregate of 6 mm;

[0037] (2) Utilize the fiber cutting machine to cut and disperse the fiber aggregates;

[0038] (3) Pave the cut and dispersed fibers into the mold through the distributor;

[0039] (4) Heat the laid glass fibers to 630°C and press them into shape under a pressure of 1.0MPa.

[0040] After rapid cooling, a dry-process glass fiber core material with good mechanical strength and no rebound is obtained.

[0041] Fabrication of vacuum insulation panels

[0042](1) Make a three-side sealed gas barrier bag, the structure of the gas barrier film is:

[0043] PET12 / vmPET12 / vmPET12 / LDPE50, where PET12 refers to a polyethylene terephthalate film with a thickness of 12 μm, and vmPET12 refers to a polyethylene terephthalate film with a thickness...

Embodiment 3

[0046] Example 3 Making a comparison sample of a common wet-process glass fiber core material VIP

[0047] (1) Make a three-side sealed gas barrier bag. The structure of the barrier film is NY12 / vmPET12 / Al6 / LDPE50, where NY12 refers to nylon with a thickness of 12 μm, and vmPET12 refers to the evaporation of metal aluminum on the surface with a thickness of 12 μm. Polyethylene terephthalate film, Al6 refers to aluminum foil with a thickness of 6 μm, and LDPE50 refers to low-density polyethylene with a thickness of 50 μm.

[0048] (2) Bake the wet core material at 200°C for 2 hours;

[0049] (3) Take out the baked core material, and install a commonly used calcium oxide desiccant inside, then quickly put it into a gas barrier bag, place it in a vacuum chamber to evacuate, and heat seal the mouth when the vacuum degree reaches 0.01Pa, and It is vented into the atmosphere, and the wet-process glass fiber core material VIP is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com