Prefabricated building block, manufacturing thereof, and method for building and forming of wall

A block and body technology, which is applied in the processing of building materials, construction, building materials, etc., can solve the problems of lack of matching positioning and connection mechanism of steel bars, occupying space of thermal insulation layer, and complex overall structure, so as to eliminate the thermal bridge effect. , The effect of improving the vertical bearing capacity and the stability of the steel skeleton structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

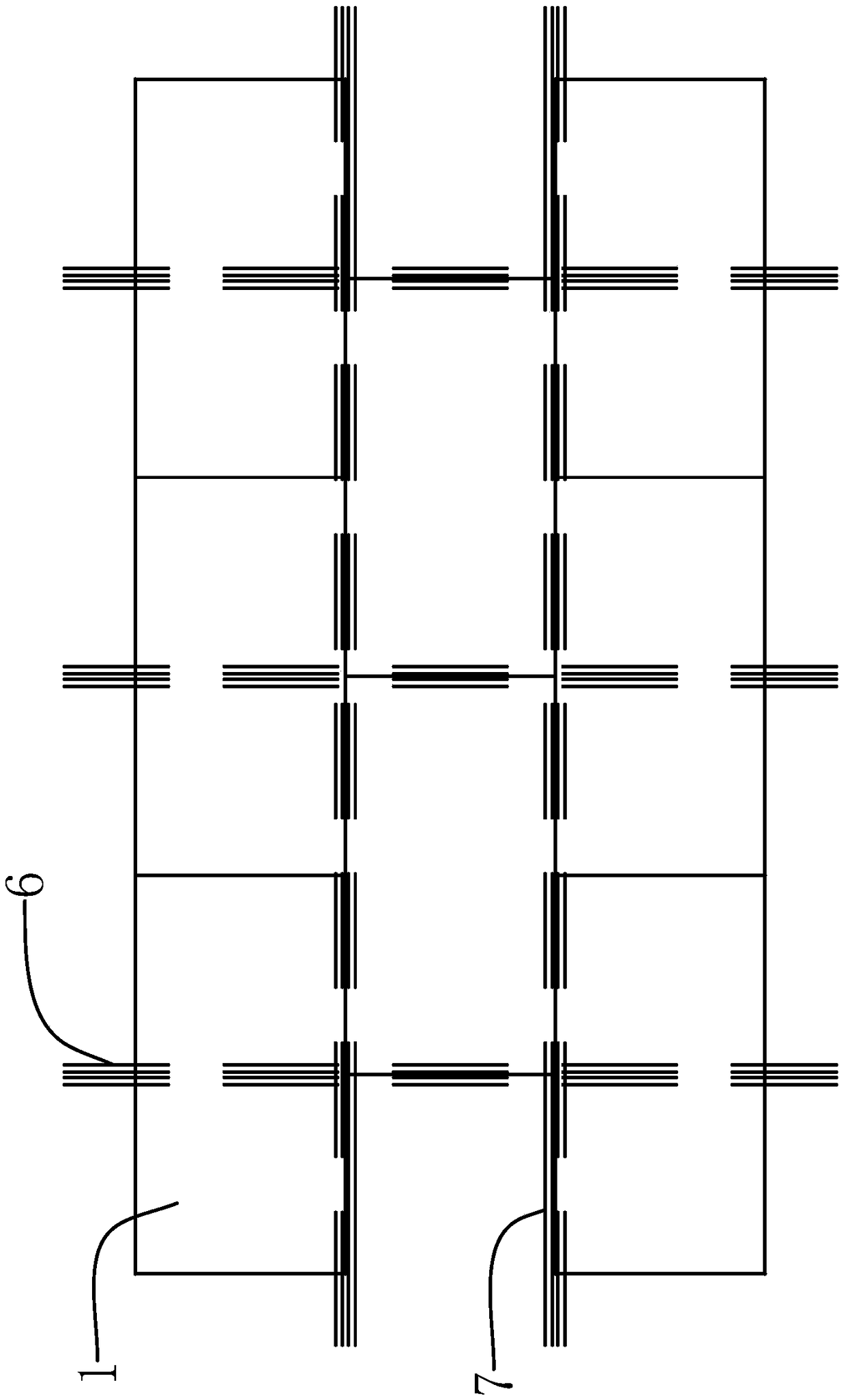

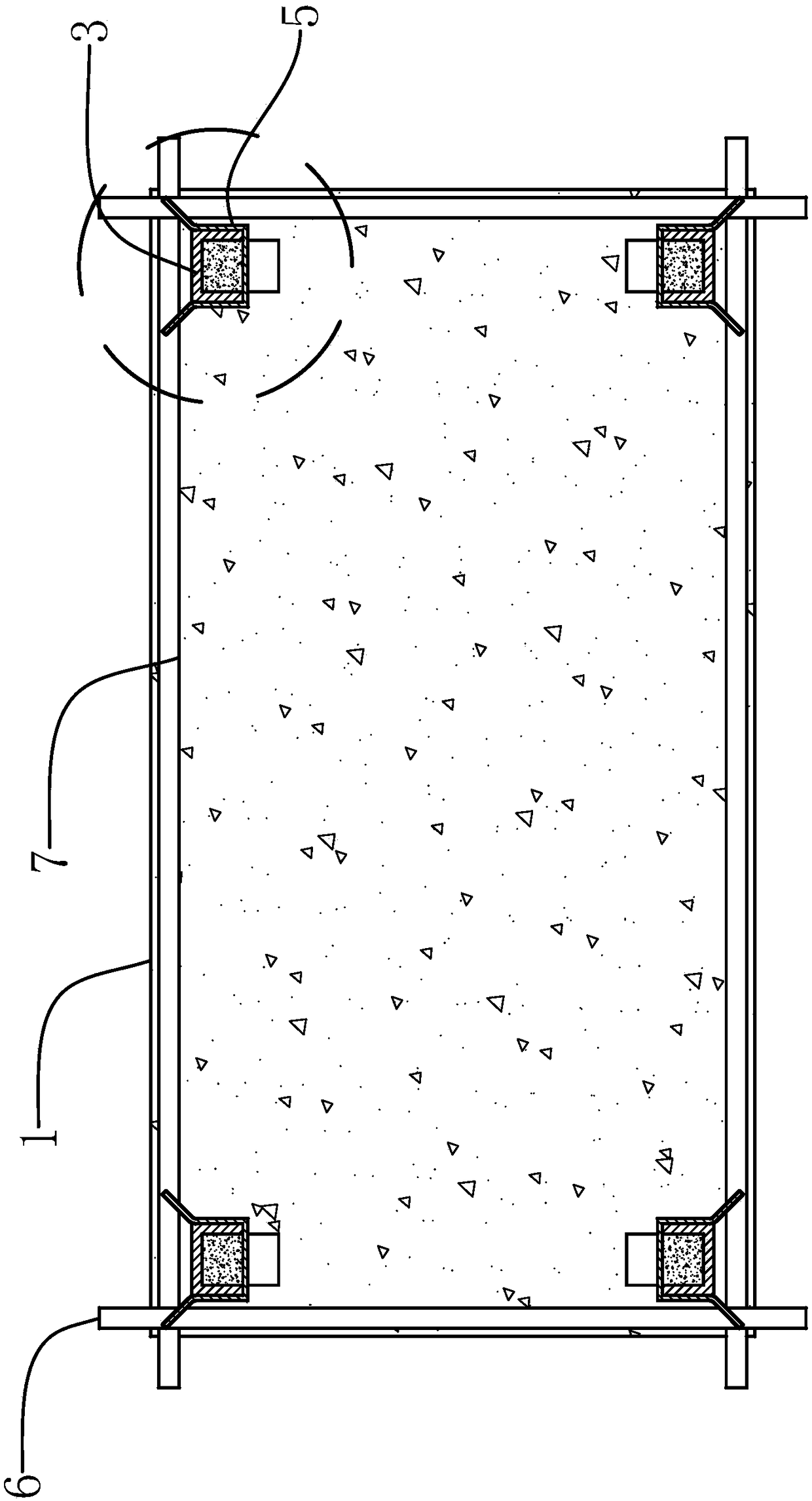

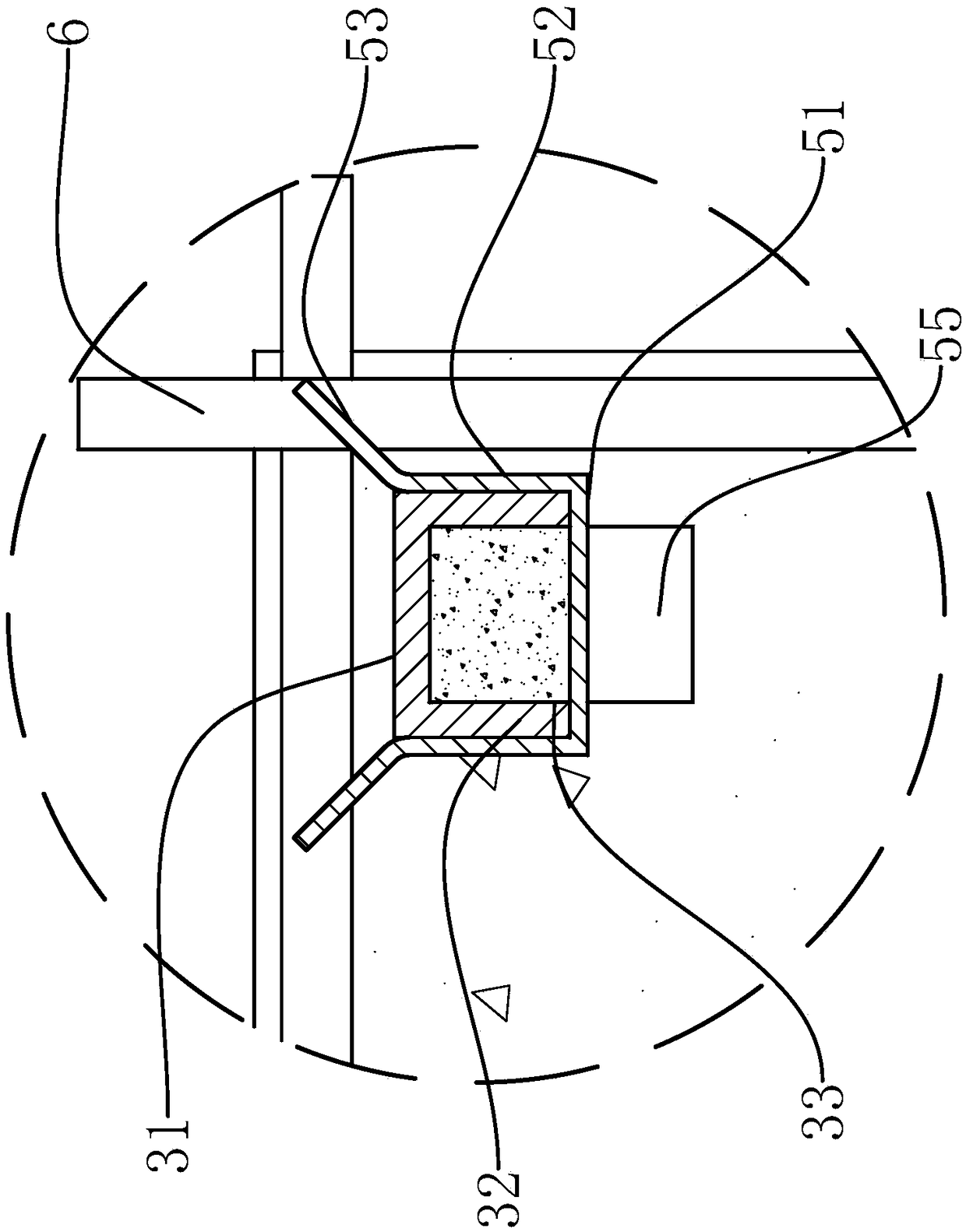

[0056] Such as Figure 1-7 As shown, a prefabricated block of the present invention includes a block body, the body includes two wall panels 1, the two sides of the wall panels 1 are parallel to each other, and the opposite sides of the two wall panels 1 are parallel to each other, and steel Skeleton, the steel skeleton includes two connecting frames, one connecting frame includes two sections of main connecting steel 2 parallel to each other in length direction and two sections of auxiliary connecting steel 3 parallel in length direction, and two sections of main connecting steel 2 and two sections of auxiliary connecting steel The steel 3 is connected and enclosed to form a closed-loop rectangular frame structure. The ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com