Vacuum insulated panel core material and preparation method thereof and vacuum insulated panel

A technology of vacuum insulation panels and core materials, which is applied to heat exchange equipment, mechanical equipment, and pipelines through heat insulation, and can solve problems such as complex processes, large thermal bridge effects, and reduced insulation performance, and achieve uniform pore distribution and environmental protection. The effect of less pollution and less thermal bridge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A vacuum insulation board core material, the density of the core material is 140kg / m 3 , the core material is wrapped with air-permeable and powder-proof non-woven fabric, and the core material includes three raw material components with a mass fraction of 60% fumed silica, 35% reinforcing adhesive fiber and 5% radiation sunscreen.

[0031] The specific surface area of the nano fumed silica is 150m 2 / g.

[0032] The molecular composition of described reinforced adhesive fiber is (C 6 h 10 o 5 ) n, the average fiber diameter is 5 μm, and the average length is 5 mm.

[0033] The radiation sunscreen is carbon black.

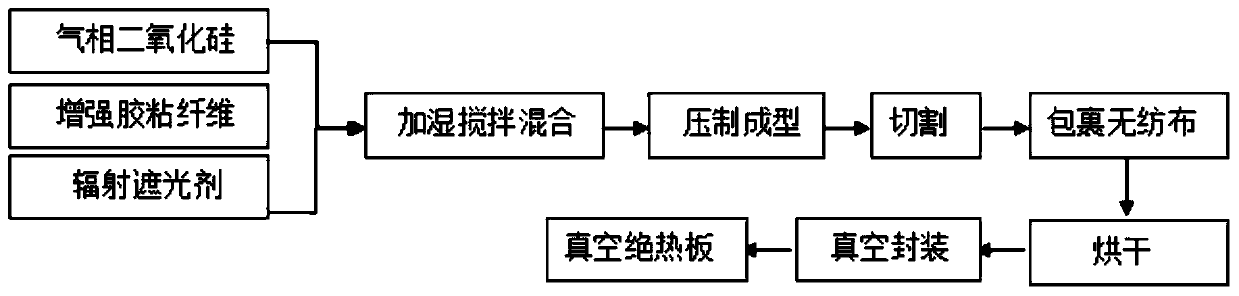

[0034] A method for preparing a core material of a vacuum insulation panel as described above, comprising the following steps:

[0035] S1 ingredients: Weigh 60kg of nano fumed silica, 5kg of radiation sunscreen agent and 35kg of reinforced adhesive fiber to prepare, and put them into the hopper of the mixer in turn, and seal the hopper;

[0036] S2...

Embodiment 2

[0046] A vacuum insulation panel core material, the density of the core material is 180kg / m 3 , the core material is wrapped with air-permeable and powder-proof non-woven fabric, and the core core material includes three raw material components with a mass fraction of 95% fumed silica, 3% reinforcing adhesive fiber and 2% radiation sunscreen .

[0047] The specific surface area of the nano fumed silica is 200m 2 / g.

[0048] The molecular composition of described reinforced adhesive fiber is (C 6 h 10 o 5 )n, the average fiber diameter is 10μm, and the average length is 10mm.

[0049] The radiation sunscreen is carbon black.

[0050] A method for preparing a core material of a vacuum insulation panel as described above, comprising the following steps:

[0051] S1 ingredients: Weigh 95kg of nano fumed silica, 2kg of radiation sunscreen agent and 3kg of reinforced adhesive fiber to prepare, and put them into the hopper of the mixer in turn, and seal the hopper;

[0052...

Embodiment 3

[0062] A vacuum insulation panel core material, the density of the core material is 180kg / m 3 , the core material is wrapped with air-permeable and powder-proof non-woven fabric, and the core material includes three raw material components with a mass fraction of 65% fumed silica, 25% reinforcing adhesive fiber and 10% radiation sunscreen.

[0063] The specific surface area of the nano fumed silica is 300m 2 / g.

[0064] The molecular composition of described reinforced adhesive fiber is (C 6 h 10 o 5 ) n, the average fiber diameter is 15 μm, and the average length is 15 mm.

[0065] The radiation sunscreen is carbon black.

[0066] A method for preparing a core material of a vacuum insulation panel as described above, comprising the following steps:

[0067] S1 ingredients: Weigh 65kg of nano fumed silica, 10kg of radiation sunscreen and 25kg of reinforced adhesive fiber to prepare, and put them into the hopper of the mixer in turn, and seal the hopper;

[0068] S2 H...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com