Multifunctional composite vacuum insulation board and manufacturing and packaging method thereof

A vacuum insulation panel and multi-functional technology, which is applied to heat exchange equipment, protects pipelines through heat insulation, heat preservation, etc., can solve the problems of easy thermal bridge effect, and the outer wall is easily punctured by impact, so as to reduce thermal bridge effect, Guaranteed thermal insulation performance and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

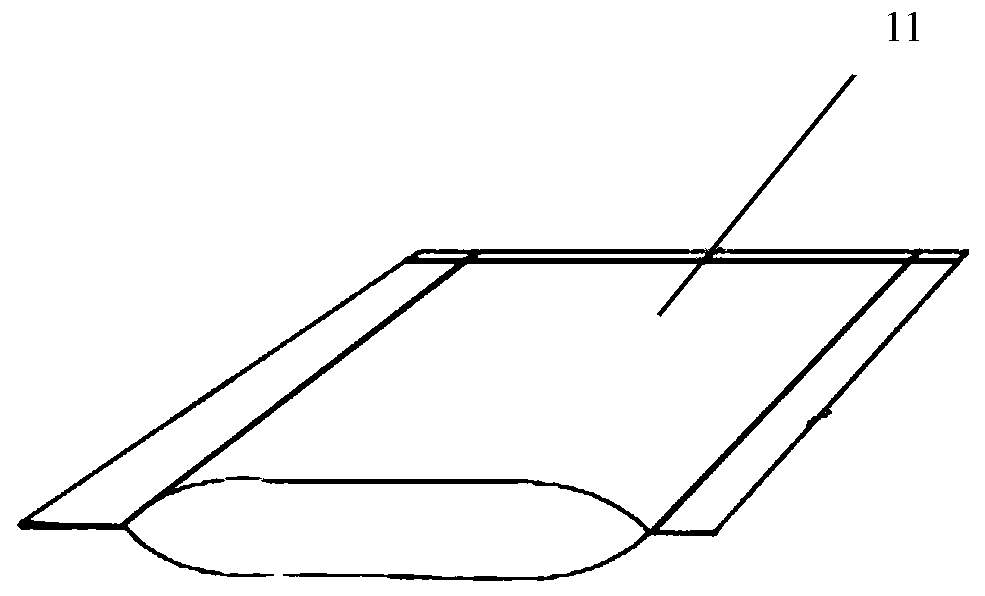

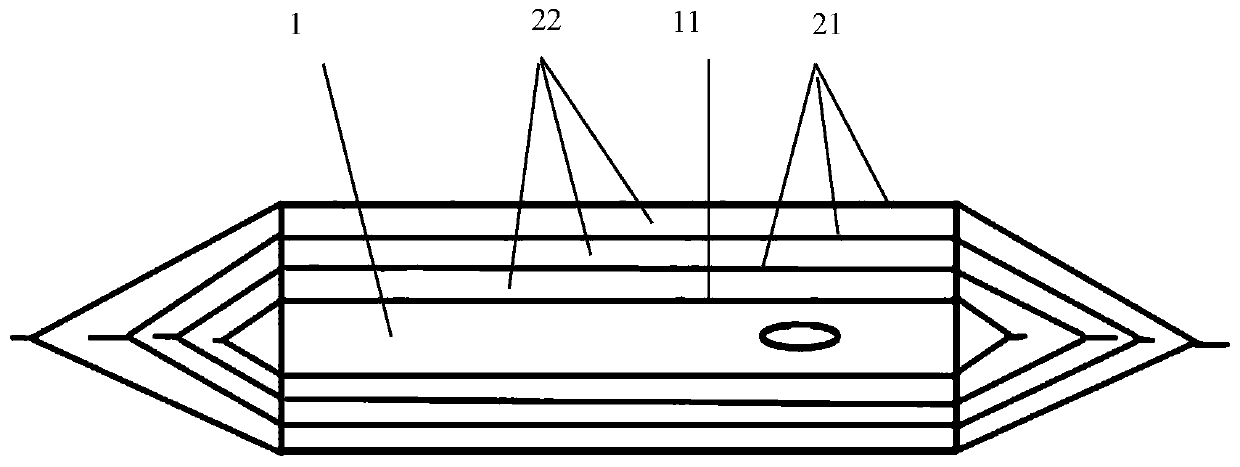

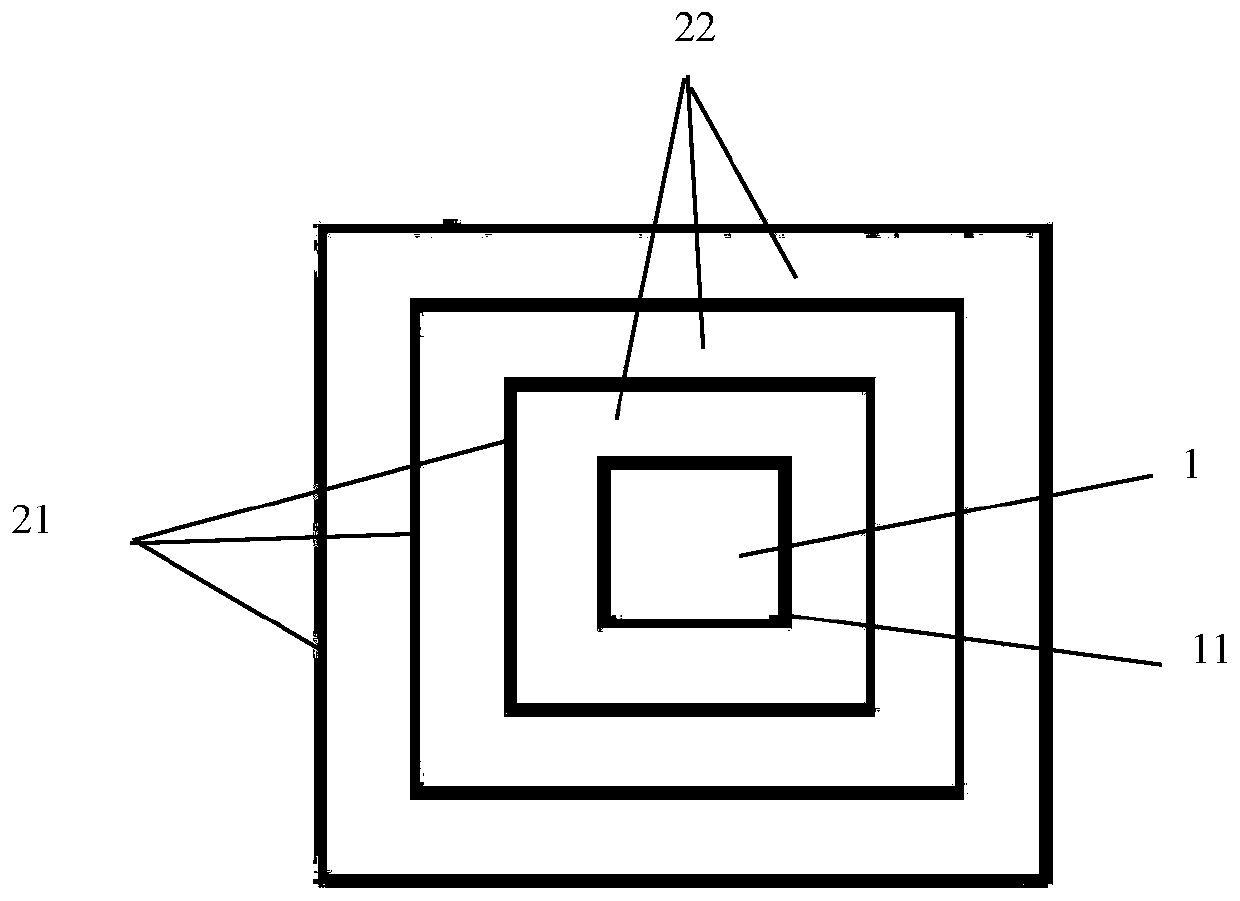

[0033] A multifunctional composite vacuum insulation panel of the present invention, please refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, it includes a single-layer vacuum insulation panel, a thermal insulation composite layer 2 and a protective layer 3. The single-layer vacuum insulation panel includes a core material 1 and a first polyester-based film 11. The core material 1 is made of glass fiber, and the core material 1 is set In the first polyester-based film 11 and vacuumized and edge-sealed to form a single-layer vacuum insulation panel, the thermal conductivity of glass fiber is low, and the thermal insulation performance is good; the thermal insulation composite layer 2 is wrapped on the outside of the single-layer vacuum insulation panel, and the single-layer vacuum insulation panel The vacuum insulation panel is sealed inside the thermal insulation composite layer 2. The thermal insulation composite layer 2 includes three layers of ...

Embodiment 2

[0043] This embodiment provides a method for manufacturing and packaging a multifunctional composite vacuum insulation panel, wherein the method for manufacturing and packaging includes the following steps:

[0044] S1: To make a single-layer vacuum insulation panel, vacuumize the core material 1 and place it in an oven to preheat for 30 minutes at a temperature of 100-125°C to remove residual moisture inside the core material 1. Put the core material 1 into the first polyester base The film 11 is placed in a vacuum chamber to evacuate, heat-sealed and cut the excess lip of the first polyester-based film 11, heat-sealed and folded, and bonded with an adhesive to form a single-layer vacuum insulation panel;

[0045] S2: The glass fiber layer 22 is preheated in the oven for 30 minutes at a temperature of 100-125°C, and the inorganic adhesive is applied on the single-layer vacuum insulation panel, and the preheated glass fiber layer 22 is evenly spread on the six surfaces of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com