Composite wall body with light steel-wood mixing keels and implementation method thereof

A composite wall and keel technology, applied in the fields of housing construction and civil engineering, can solve the problems of inability to exert the strength of light steel components, reduce the mechanical properties of light steel keels, and reduce economic benefits, and achieve light weight, convenient construction, and energy reduction. The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

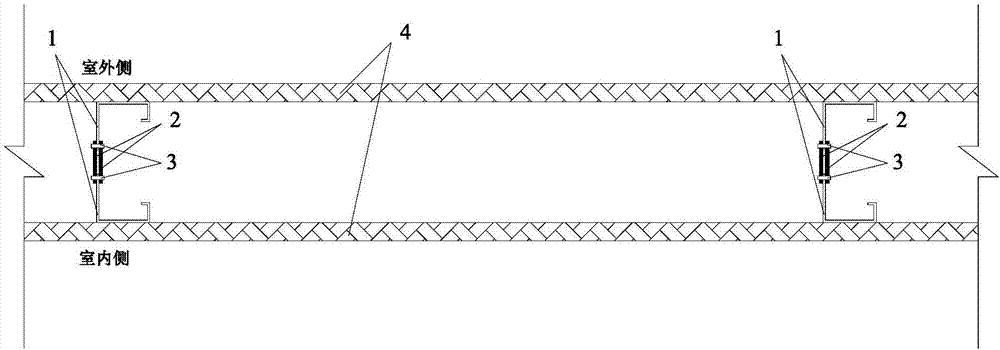

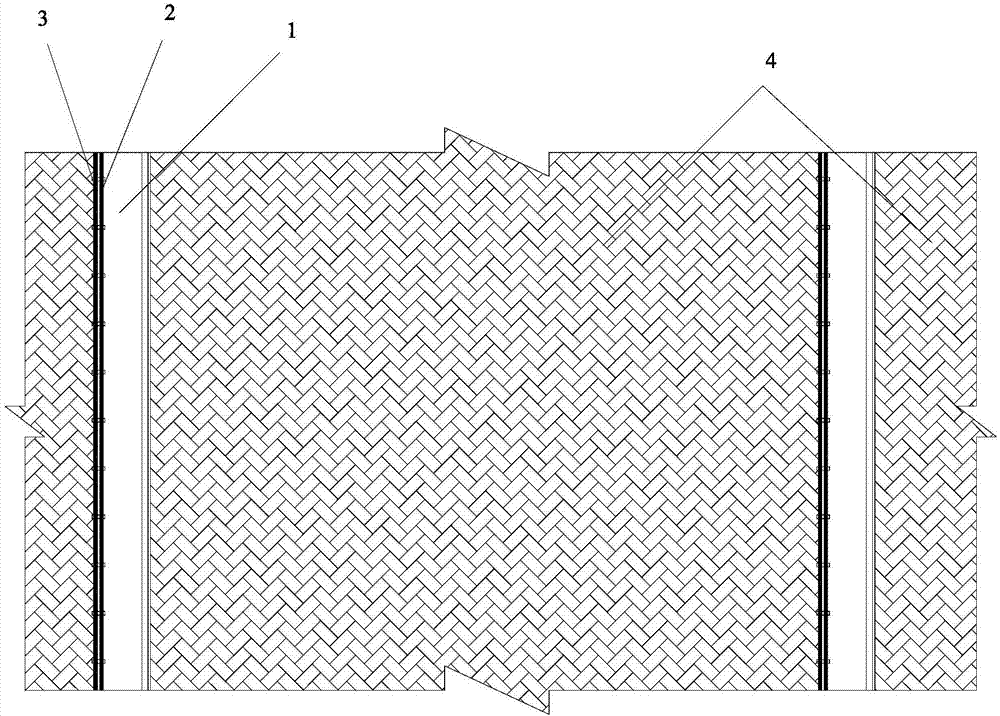

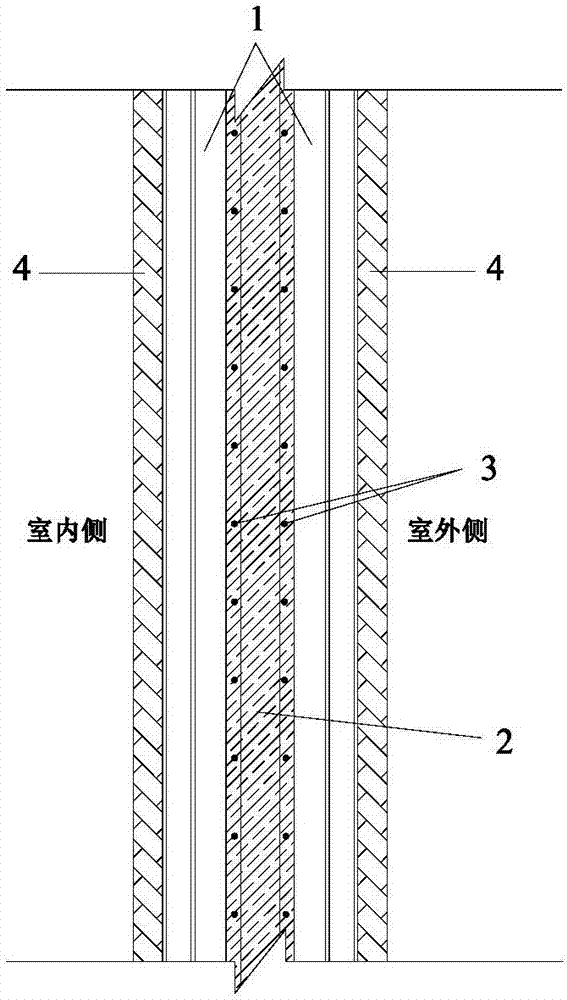

[0034] Such as Figure 1 to Figure 4 As shown, it includes cold-formed thin-walled steel 1, cork board 2, self-tapping screws 3 and light board 4, and the light board 4 forms an outer cladding wallboard.

[0035] Further, the cold-formed thin-walled section steel 1 is a split hemmed channel steel, that is, the cold-formed thin-walled hemmed channel steel is divided into two parts along the neutral axis of the web, and placed in the steel-wood mixed section respectively. The upper and lower sides of the keel. The type of channel steel selected depends on the load level of the wall, and the steel is Q235 steel or Q345 steel. The keel in the outer wall is mainly subjected to bending under the action of horizontal load. Placing the split cold-formed thin-walled steel 1 on both sides of the mixed keel can maximize the flexural performance of the keel and maximize the strength of the steel. high feature.

[0036] Further, there are two cork boards 2 that make up the wooden keel, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com