A vacuum insulation panel, cold storage box and production method thereof

A technology of a vacuum insulation panel and a production method, which is applied in the direction of protecting pipelines through thermal insulation, thermal insulation, pipeline protection, etc., can solve problems such as affecting the service life, difficult to automate equipment, affecting the thermal insulation performance of the box body, etc., so as to improve wear resistance and performance. Impact resistance, precise dimensions, and improved cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

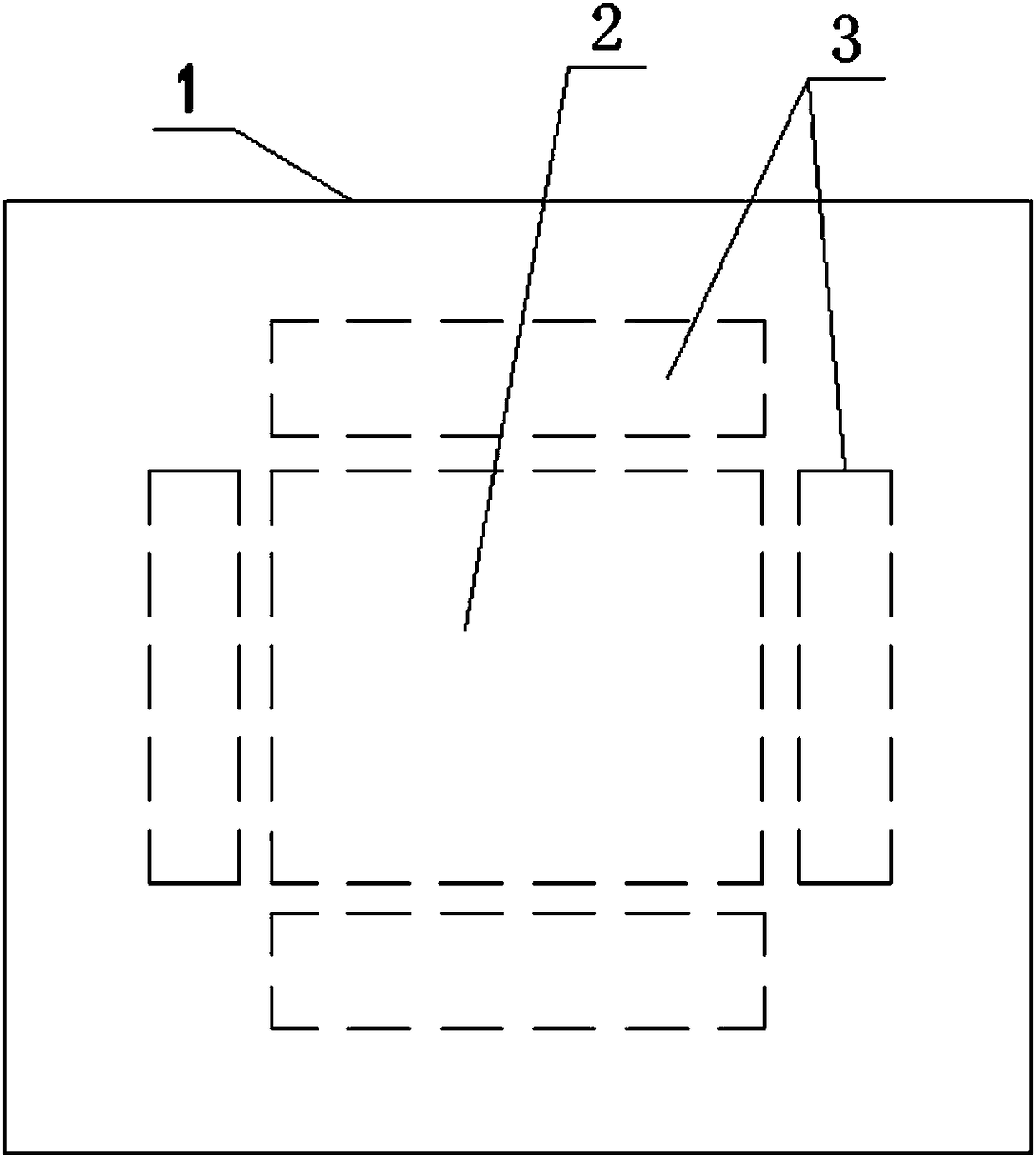

[0036] A vacuum insulation panel, which includes: a core board 2, a film bag 1 that seals and covers the core board 2 and is evacuated, and a folded board 3 is provided in the film bag 1 and on the same plane around the core board, The materials of the core plate 2 and the folded plate 3 can be the same or different (mainly choose glass fiber laminated material, silica plate, or a mixture of the two); , and the core plate 2 form a box 4 with only one side open.

[0037] The thickness of the core plate 2 and the folded plate 3 is 1-5 cm, which is set according to actual needs.

[0038] Such as figure 1 , each folded plate 2 and the core plate 3 are distributed alternately; the thickness of the core plate is uniform, and the distance between each folded plate and the core plate is 1.2-2 times the thickness of the core plate;

[0039] The film bag 1 is rectangular, and when the core plate 2 and the folded plates 3 are on the same plane, the film material edge material at the fo...

Embodiment 2

[0041] On the basis of Embodiment 1, there are the following modifications in this embodiment:

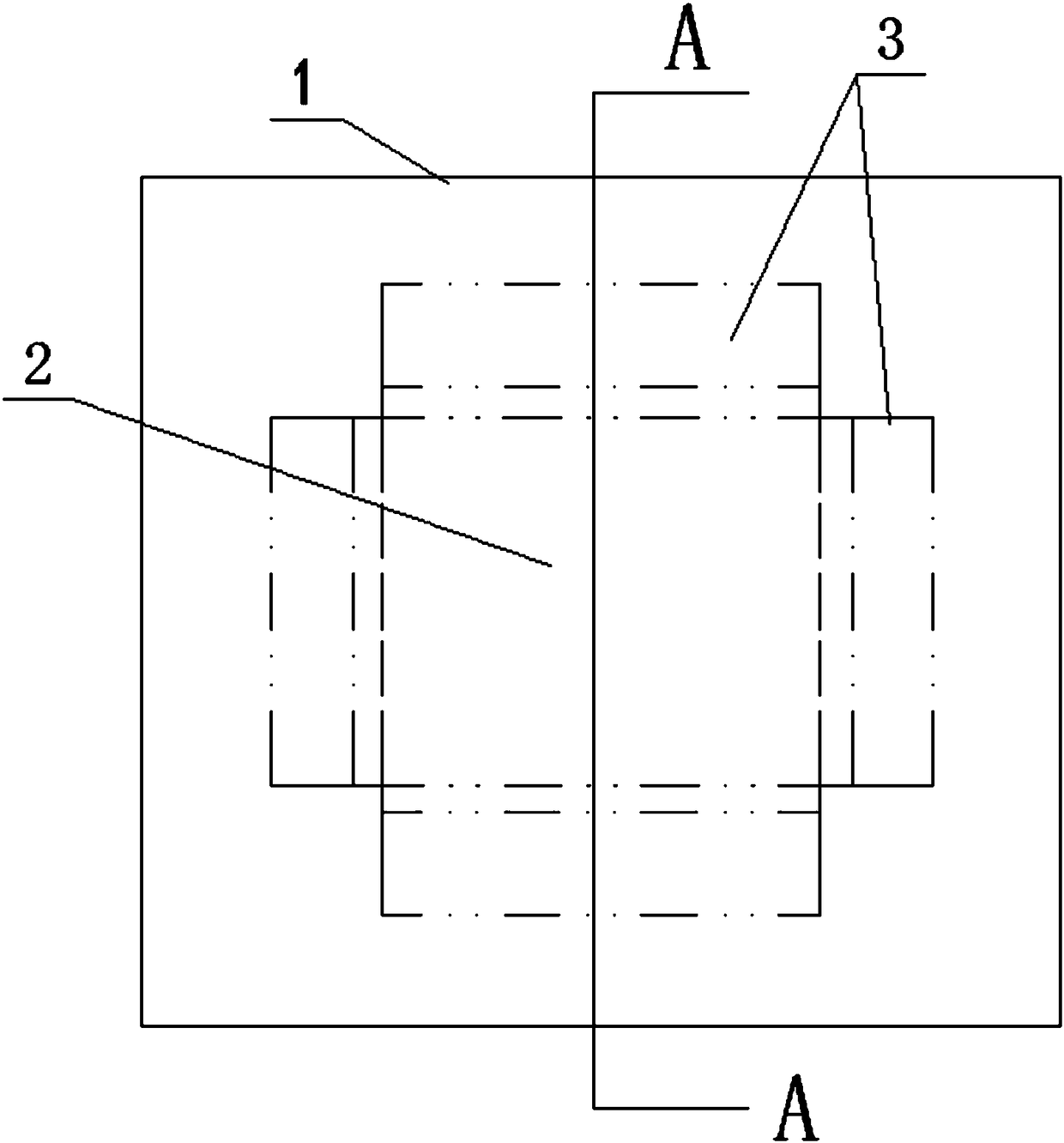

[0042] Such as figure 2 Each folded plate and the core plate form an integral body, and there is a strip-shaped groove at the connection between each folded plate and the core plate; the strip-shaped groove is formed by pressing, cutting, or laying when the core material is laid. The width of the strip-shaped groove is 0.8-1.5 times of the thickness of the core plate.

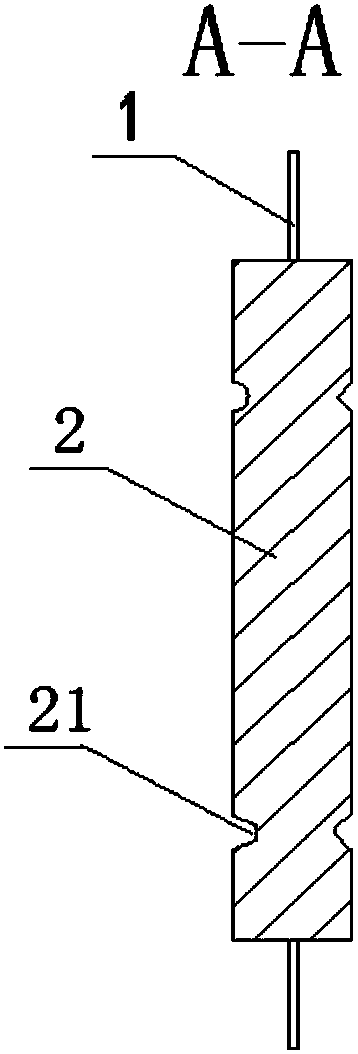

[0043] Such as image 3 , the section of the strip groove is U-shaped or V-shaped or arc-shaped.

[0044] Optionally, the strip-shaped grooves are distributed on the front and back sides of the connection between each folded plate and the core plate, so as to reduce the stretching amount of the film material of the film bag when the folded plates are folded, and avoid damage to the film material.

[0045] The core material is polygonal (specifically triangular, quadrangular, pentagonal, hexagonal, etc.), and the...

Embodiment 3

[0047] On the basis of embodiment 1 or 2, there are the following modifications in this embodiment:

[0048] The production method of the cold storage box includes: placing the box body into a mold, injecting foam material into the mold, so that the inner and outer walls of the box body are coated with foam material, such as Figure 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com