Cold chain thermal insulation box and manufacturing method thereof

An incubator and cold chain technology, applied in the field of cold chain insulation, achieves the effects of low raw material cost, low equipment and process cost, and low thermal bridge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

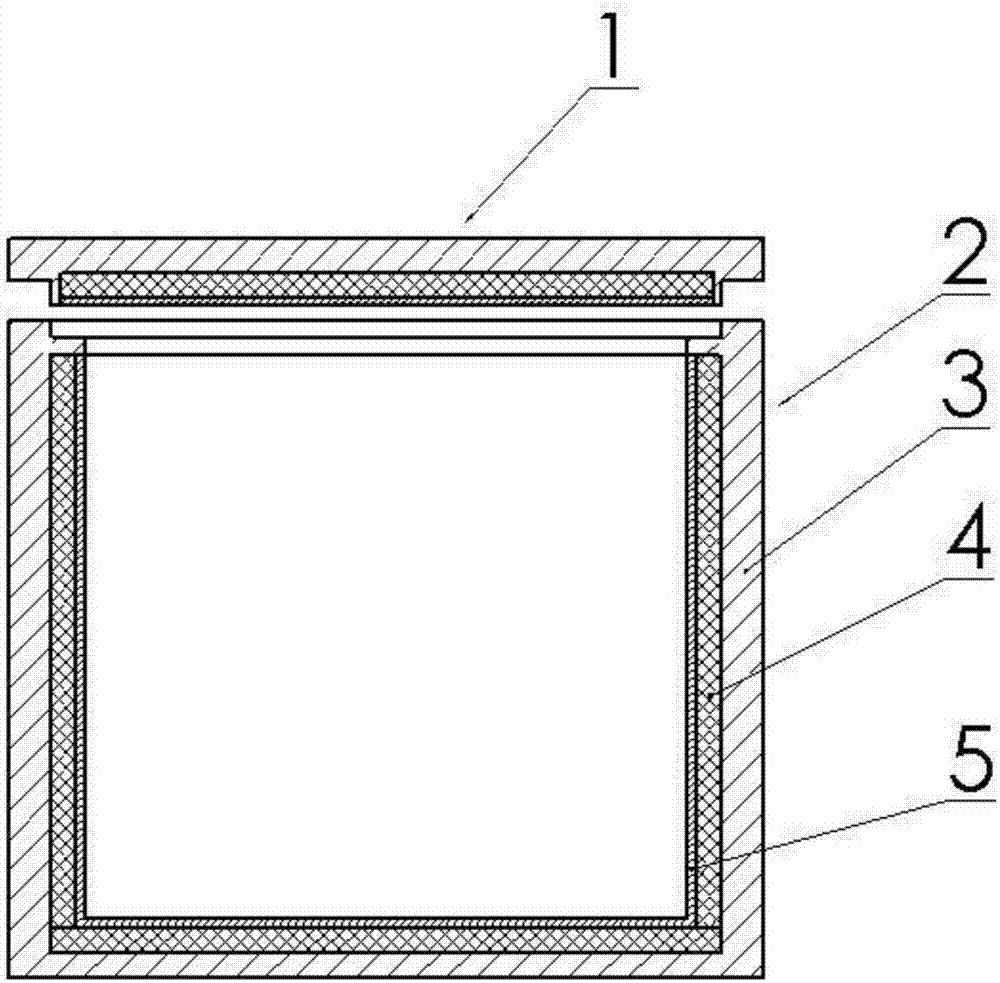

Method used

Image

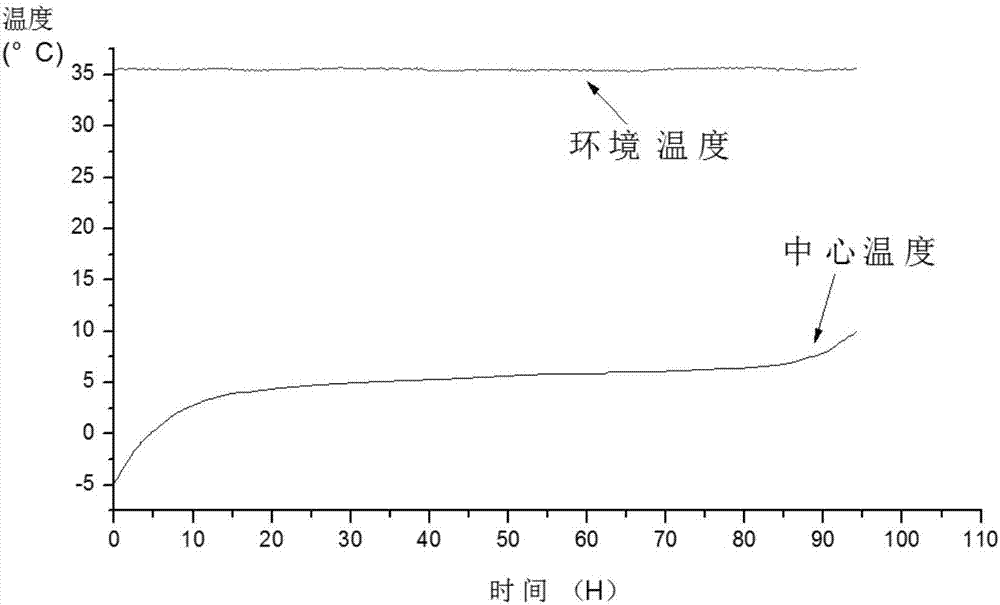

Examples

Embodiment 2

[0059] The difference between this embodiment and embodiment 1 is that the EPP material is replaced by EPS (polystyrene foam) material. Correspondingly, in step 6 of the production process, the temperature of the steam used for foaming the EPS particles is 90-110° C., and the steam pressure is 0.1 MPa-0.4 MPa. All the other parts are the same as in Embodiment 1, and the structure of the cold chain incubator is also the same as in Embodiment 1, so no further details are given.

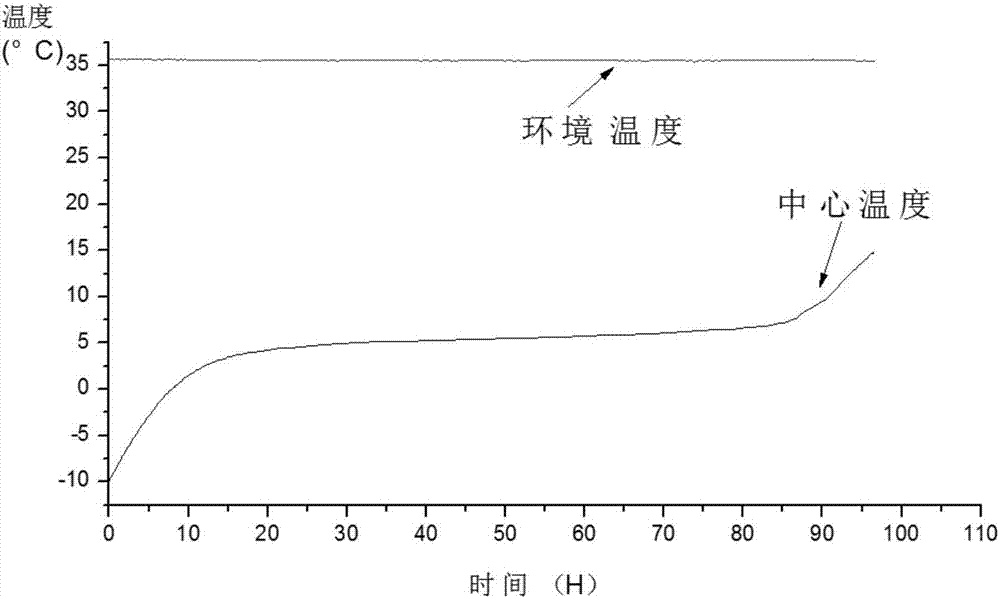

[0060] further reference image 3 , the EPS and VIP integrally molded cold-chain incubator provided in this example has a size of 420mm*350mm*240mm, and the thickness of VIP is 10mm. The cold-chain incubator is placed in 6.15kg of cooling agent at an ambient temperature of 37°C. The change of the temperature in the center of the box is as follows: image 3 As shown, the time for maintaining the temperature in the center of the box below 8°C is 87.2 hours, and the time for maintaining the temperature i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com