A kind of prefabricated concrete sandwich insulation exterior wall panel and preparation method thereof

A prefabricated concrete and thermal insulation exterior wall technology, applied in the direction of walls, buildings, building components, etc., can solve the problems of high thermal conductivity, affecting the thermal insulation effect of prefabricated concrete sandwich thermal insulation external wall panels, and low fire rating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

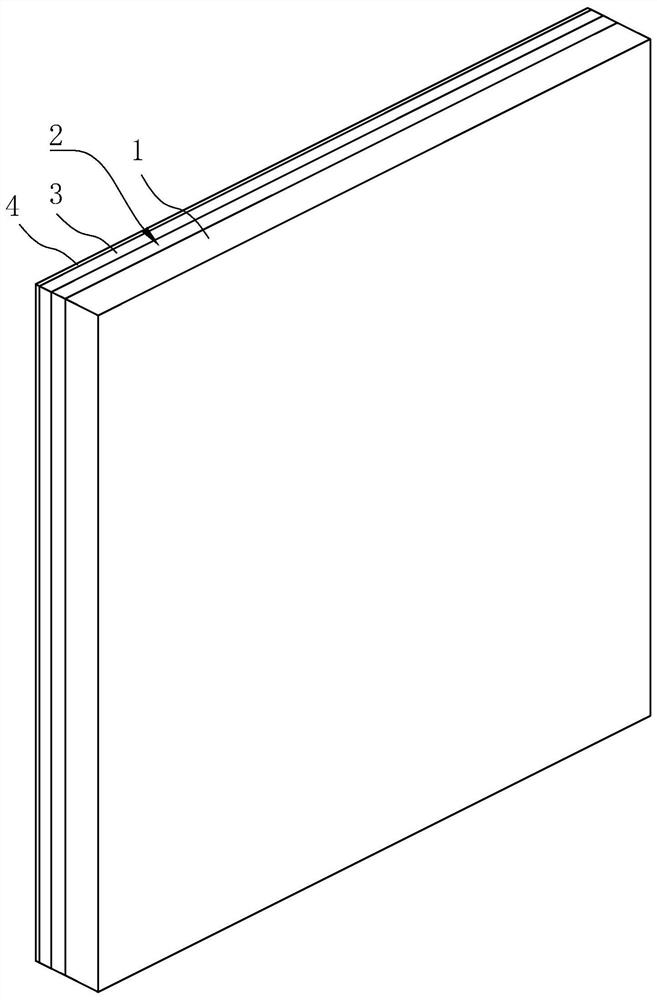

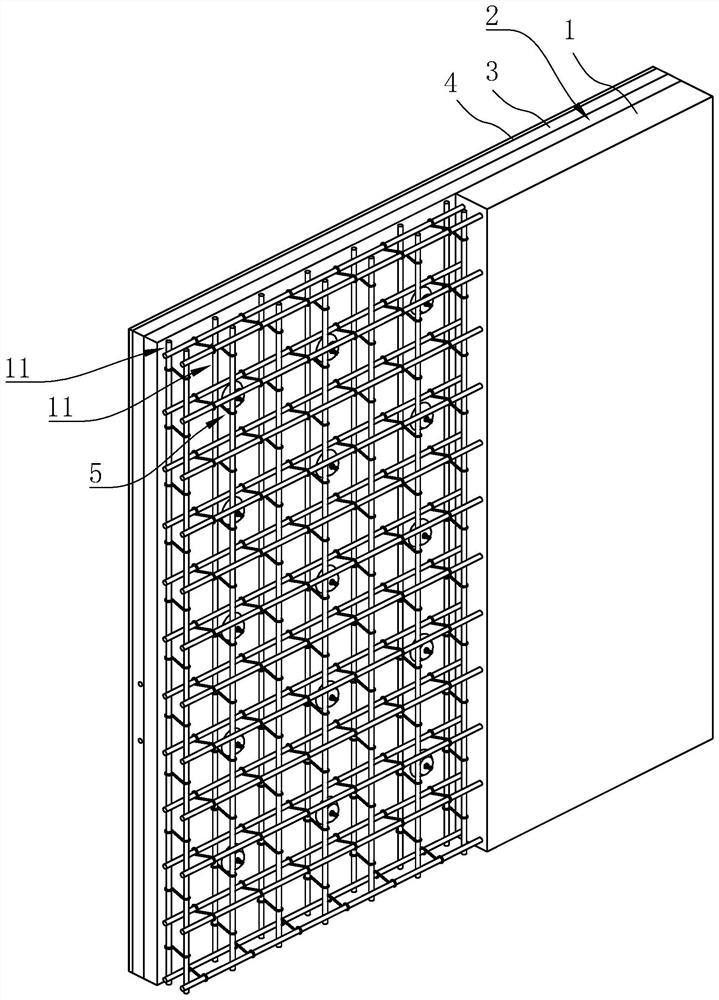

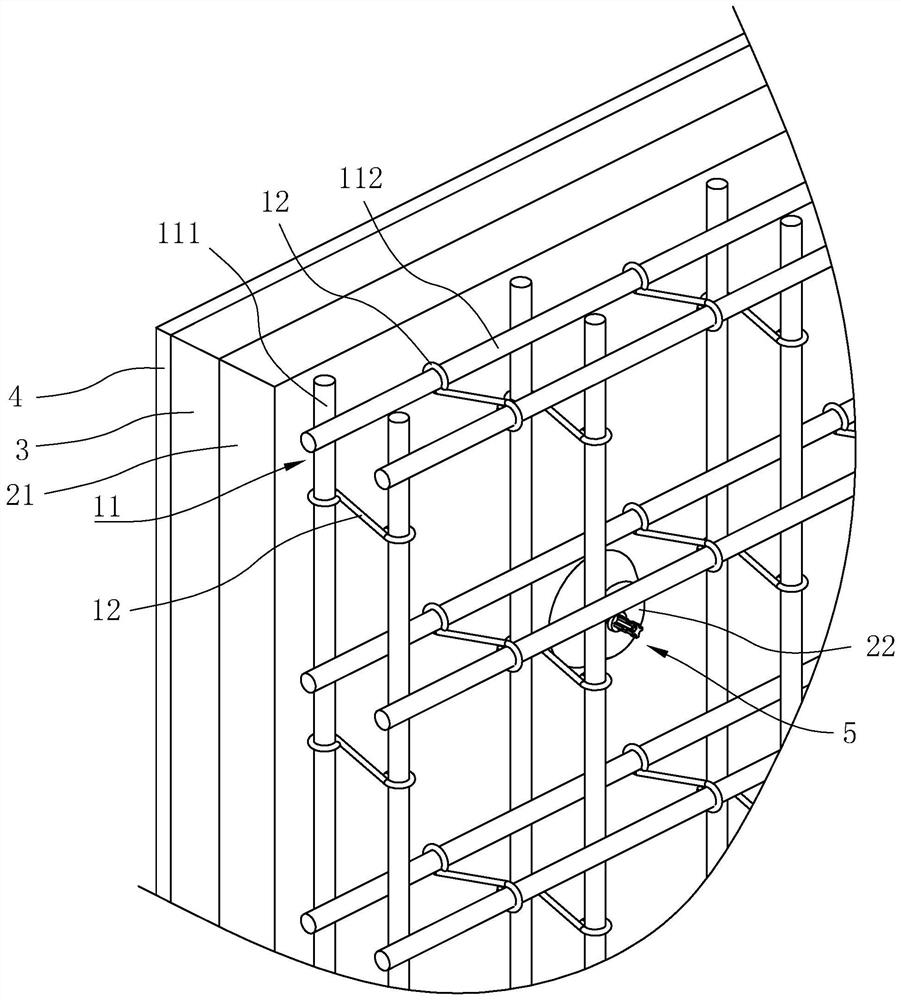

[0046] A kind of prefabricated concrete sandwich insulation exterior wall panel and its preparation method, such as figure 1 and figure 2 As shown, the inner leaf concrete wall panel 1 is included, the side of the inner leaf concrete wall panel 1 is provided with an airgel fiber felt 2, and the side of the airgel fiber felt 2 away from the inner leaf concrete wall panel 1 is provided with an outer leaf concrete wall panel 3. A decorative panel 4 is provided on the side of the outer leaf concrete wall panel 3 away from the airgel fiber felt 2 .

[0047] Such as figure 2 and image 3 As shown, the inner leaf concrete wall panel 1 is formed by pouring ordinary concrete, and the thickness of the inner leaf concrete wall panel 1 is 50-300 mm. In this embodiment, the thickness of the inner leaf concrete wall panel 1 is 180 mm. Inside the inner...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com