Partially cladding steel-concrete composite member and composite structure building thereof

A technology of combined components and combined structures, which is applied in the direction of buildings, structural elements, building components, etc., can solve the problems of high cost of anti-corrosion and fire protection, and achieve the effects of good anti-corrosion and fire protection performance, improved durability, and strong integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

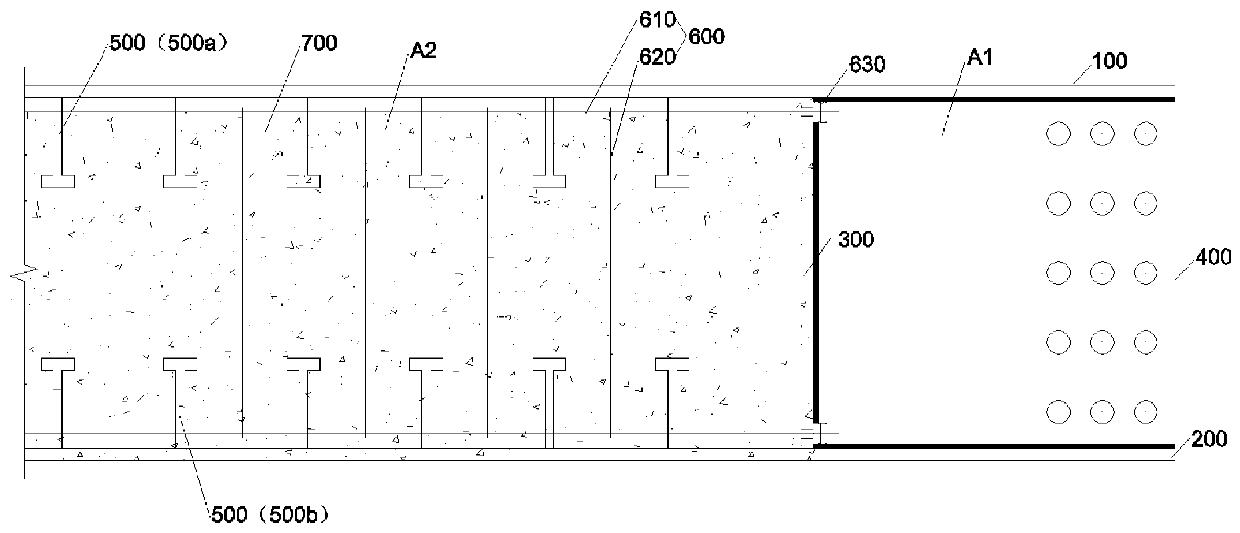

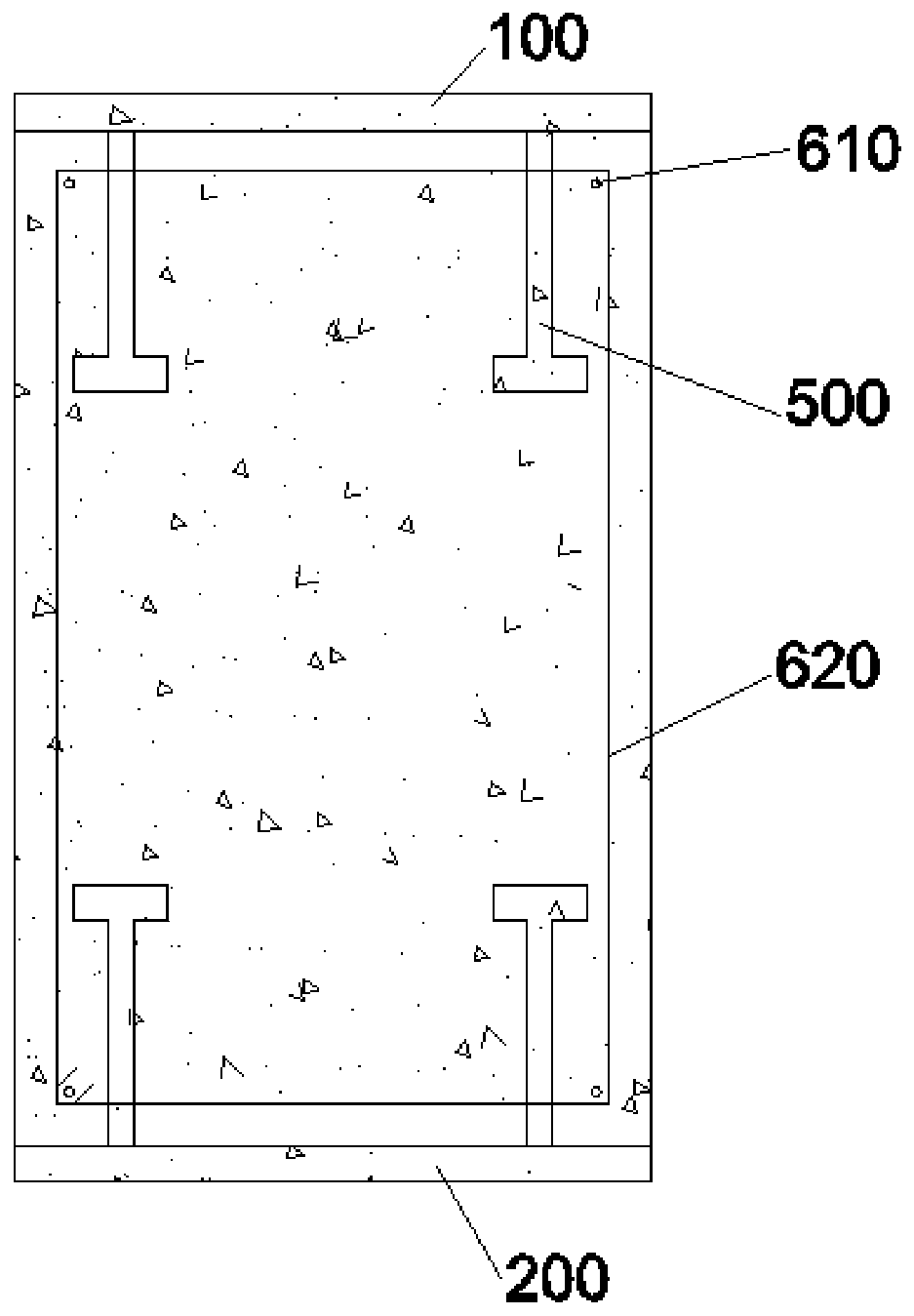

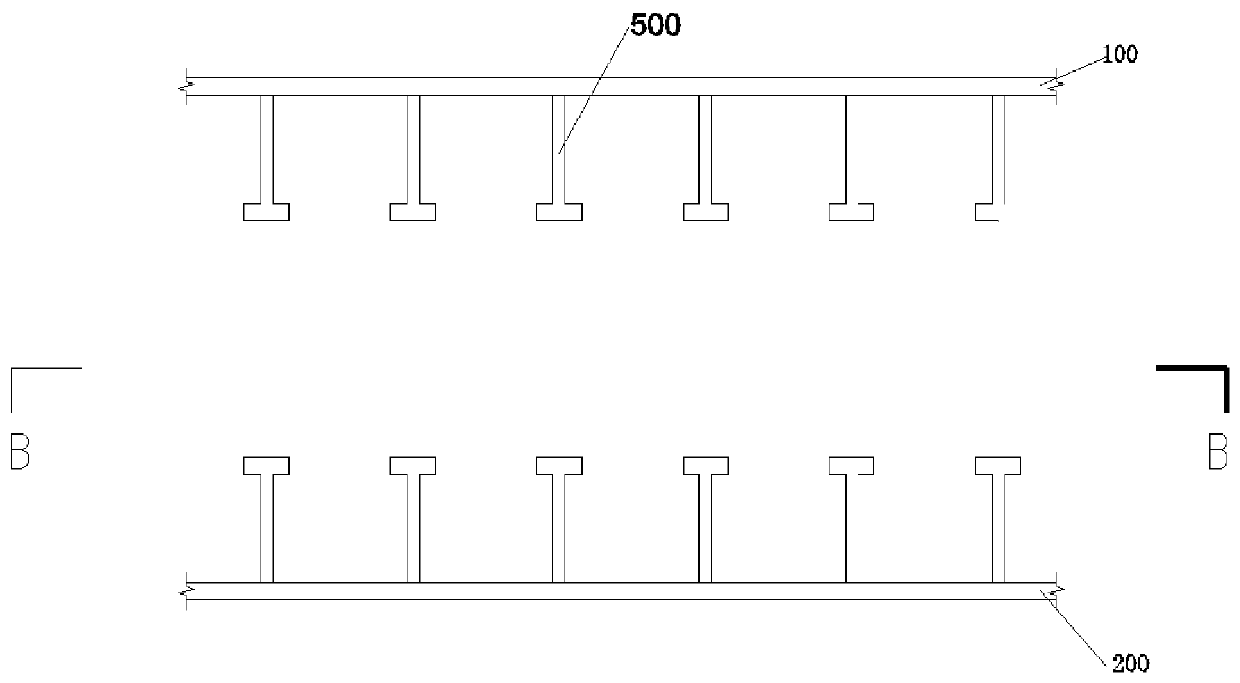

[0098] Such as Figure 1-4 As shown, a partially clad steel-concrete composite member provided in this embodiment includes: a first side steel plate 100, a second side steel plate 200, a stud 500, a repair welding steel plate 400, a stiffening steel plate 300, a steel skeleton 600 and Concrete 700.

[0099] The first side steel plate 100 and the second side steel plate 200 are arranged in parallel and spaced; It is fixedly connected with the second side steel plate 200.

[0100] The two stiffened steel plates 300 divide the partly clad steel-concrete composite member into the connection area A1 on the outside of the two stiffened steel plates 300, and the prefabricated area A2 between the two stiffened steel plates 300; the two stiffened steel plates 300 and the first side steel plate 100 and the second side steel plate 200 enclose a prefabricated abdominal cavity in the prefabricated area A2; concrete 700 is poured in the prefabricated abdominal cavity; a steel skeleton 600 i...

Embodiment 2

[0125] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that:

[0126] Such as Figure 7 As shown, the partially clad steel-concrete composite member 3 is embedded in the wall 4 as a column; the partially clad steel-concrete composite member 3 is coated with an external anti-corrosion layer on the outer surface of the outer steel plate 3a near the outer side of the wall (not shown), a glass wool board 10 is laid on the outer anti-corrosion layer, which is used to block part of the coated steel-concrete composite member as a thermal bridge to transfer heat flow between the indoor and outdoor sides of the wall body 4 . On the projection plane parallel to the wall 4 , the format size of the glass wool board does not cover the entire wall 4 , and the format of the glass wool board only covers all or part of the cladding steel-concrete composite member 3 .

[0127] Different from the thermal insulation board or thermal insulation la...

Embodiment 3

[0142] This embodiment discloses a composite structure building, such as Figure 8 As shown, it includes: beams (not shown), columns 30 , shear walls 40 and floors (not shown).

[0143] Wherein, the column body 30 is composed of a partially clad steel-concrete composite member in Embodiment 1 or 2. A shear wall 40 is arranged between the two columns 30 .

[0144] The shear wall 40 includes a body of wall and a wall connector 43 arranged in the wall; the body of the wall includes an inner plate 41 and an outer plate 42 arranged at intervals along its thickness direction; two ends of the inner plate 41 and the outer plate 42 are provided with The end plate 45 is fixedly connected to the first side steel plate and the second side steel plate on the column body 30 through the end plate 45 . In order to avoid the thermal bridge effect, the end plates can also be omitted, and the inner and outer plates are directly connected to the side steel plates on the column.

[0145] The wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com