High-temperature-resisting gel composite heat-preservation material

A technology of composite thermal insulation material and airgel, which is applied in the field of industrial thermal insulation materials, can solve the problems of fragile thermal insulation performance, low efficiency, loss, etc., and achieve the effects of reducing thermal bridge effect, simple process technology and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

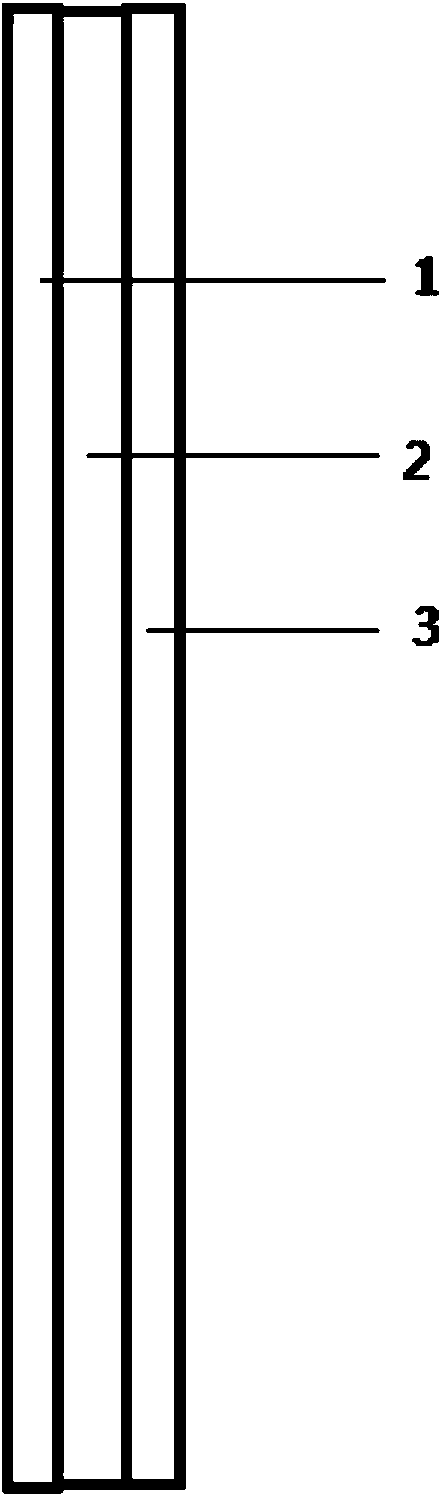

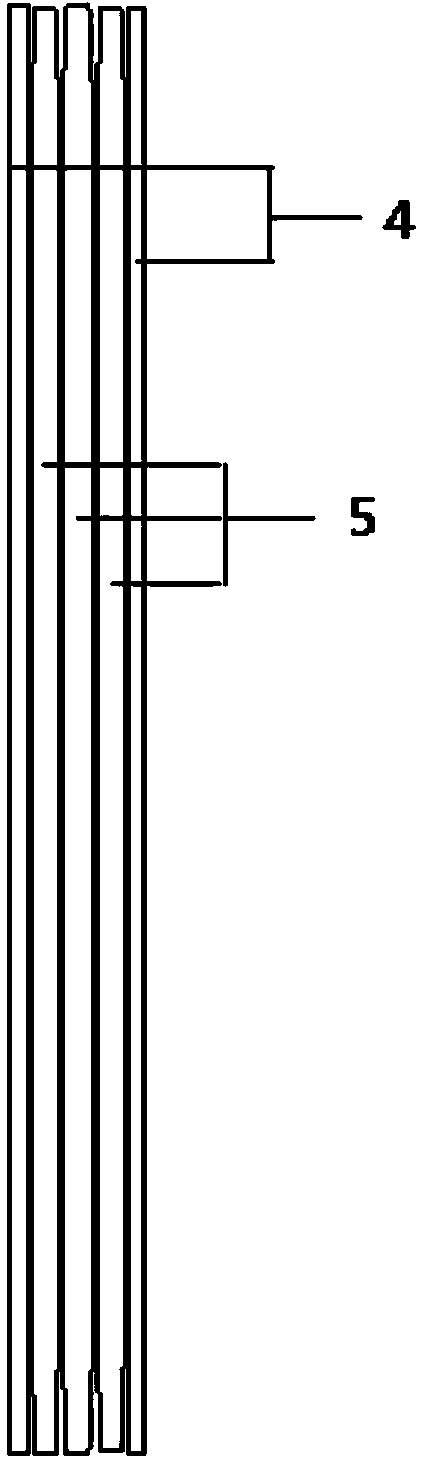

[0023] as attached figure 1 and attached figure 2 As shown, this embodiment provides a high temperature-resistant aerogel composite thermal insulation material, which is composed of an inner inorganic fiber layer 1 , a nano-core layer 2 and an outer inorganic fiber layer 3 that are sequentially combined. The nano-core layer 2 is composed of a protective layer 4 provided on the outer side and a nano-material layer 5 in the middle. In this example, the aluminum silicate fiber blanket and aluminum foil are purchased from the market, the inorganic fiber cloth is produced by Suzhou Haizhuo Special Textile Co., Ltd., and the aerogel powder is produced by Shenzhen Youna Technology Co., Ltd. The agent adopts LY-1300 high temperature binder produced by Zhejiang Deqing Lanya Crystal Fiber Co., Ltd.

[0024] Preferably, the inner inorganic fiber layer 1 and the outer inorganic fiber layer 3 are both composed of a blanket made of aluminum silicate fiber material.

[0025] Preferably, ...

Embodiment 2

[0035] as attached figure 1 and attached figure 2 As shown, this embodiment provides a high temperature-resistant aerogel composite thermal insulation material, which is composed of an inner inorganic fiber layer 1 , a nano-core layer 2 and an outer inorganic fiber layer 3 that are sequentially combined. The nano-core layer 2 is composed of a protective layer 4 provided on the outer side and a nano-material layer 5 in the middle. The ceramic fibers described in this example were purchased from the market, the inorganic fiber cloth was produced by Suzhou Haizhuo Special Textile Co., Ltd., the aerogel powder was produced by Shenzhen Youna Technology Co., Ltd., and the high-temperature binder was produced by Zhejiang Deqing LY-1300 high temperature adhesive produced by Lanya Crystal Fiber Co., Ltd.

[0036] Preferably, both the inner inorganic fiber layer 1 and the outer inorganic fiber layer 3 are composed of ceramic fibers.

[0037] Preferably, the connection between the in...

Embodiment 3

[0047] as attached figure 1 and attached figure 2 As shown, this embodiment provides a high temperature-resistant aerogel composite thermal insulation material, which is composed of an inner inorganic fiber layer 1 , a nano-core layer 2 and an outer inorganic fiber layer 3 that are sequentially combined. The nano-core layer 2 is composed of a protective layer 4 provided on the outer side and a nano-material layer 5 in the middle. The magnesium silicate fiber blanket and aluminum sheet described in this example are purchased from the market, the inorganic fiber cloth is produced by Suzhou Haizhuo Special Textile Co., Ltd., and the aerogel powder is produced by Shenzhen Youna Technology Co., Ltd. The binder is LY-1300 high temperature binder produced by Zhejiang Deqing Lanya Crystal Fiber Co., Ltd.

[0048] Preferably, the inner inorganic fiber layer 1 and the outer inorganic fiber layer 3 are both composed of magnesium silicate fiber blankets.

[0049]Preferably, the connec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com