Prefabricated overhead heat insulation pipe

A technology of thermal insulation pipe and thermal insulation layer, which is applied in the direction of thermal insulation, pipeline protection through thermal insulation, pipeline protection, etc. It can solve the problem that thermal insulation pipeline production can only be produced on the construction site, thermal insulation structure heat loss and thermal insulation structure are easily damaged, and product quality is difficult to achieve. Guarantee and other issues, to achieve the effect of less thermal bridge effect, increased thermal insulation effect, and product quality control

Active Publication Date: 2014-08-06

宁波万里管道有限公司

View PDF6 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to provide a thermal insulation effect in view of the problems that the heat loss of the thermal insulation structure of the traditional overhead pipeline is relatively high, the thermal insulation structure is easily damaged, the production of the thermal insulation pipeline can only be produced on the construction site, the production efficiency is low, and the product quality is difficult to guarantee. Very good prefabricated overhead insulation pipe with high internal compressive strength

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

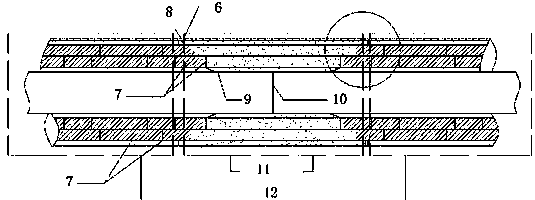

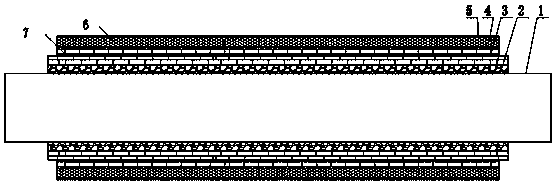

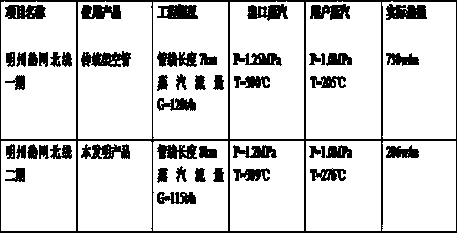

The invention provides a prefabricated overhead heat insulation pipe. In order to solve the problems that when an overhead pipe delivers hot air at a long distance, heat loss is high, and the construction cycle is long, according to the scheme, the prefabricated overhead heat insulation pipe comprises a working pipe. The prefabricated overhead heat insulation pipe is characterized in that the working pipe is wrapped in an inorganic heat insulation layer, an organic heat insulation layer and an outer protection pipe in sequence, and a protection layer is arranged between the inorganic heat insulation layer and the working pipe; longitudinal joints and transverse joints of the inorganic heat insulation layer, the organic heat insulation layer and the outer protection pipe are all in lap joint in a step shape in a staggered mode; the protection layer is connected in a pressed mode; the lap joint of the inorganic heat insulation layer and the organic heat insulation layer is provided with gaps. According to the measures, compared with a traditional prefabricated overhead heat insulation pipe, the prefabricated overhead heat insulation pipe is lower in heat loss, shorter in construction cycle and more environmentally friendly.

Description

technical field The invention relates to an optimized heat transmission pipeline technology, in particular to an optimized prefabricated overhead thermal insulation pipeline for steam transmission. Background technique During the construction of the pipeline network of the heating company, the heat loss of the pipeline is a very important indicator of pipeline construction. With the emphasis on environmental protection from all walks of life, small coal-fired boilers used for district heating will be gradually dismantled, and the required heat energy will be centrally supplied by large power plants using long-distance heating networks, which will require more heat loss control for thermal insulation pipes. high. During the transmission process of traditional overhead steam pipelines, due to temperature differences and other reasons, heat exchange occurs between the transported medium and the surrounding environment, which will inevitably generate a large amount of heat loss...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F16L59/02F16L59/12F16L59/08B29C44/12

CPCB29C44/12F16L59/025F16L59/08

Inventor 何其霖何国平胡良余徐文龙孙世新顾景磊杨海亮

Owner 宁波万里管道有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com