Insulation board of concrete exterior wall

A technology for thermal insulation boards and concrete exterior walls, which is applied in thermal insulation, solid waste management, climate sustainability, etc., can solve problems such as reducing the effect of energy saving and thermal insulation, and achieve excellent heat absorption and thermal insulation effect, high flexural strength, and foundation treatment costs. reduced effect

Inactive Publication Date: 2009-12-09

无锡市康顺节能材料科技有限公司

View PDF0 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the external walls made of energy-saving and heat-insulating blocks also have the problem of thermal bridges that reduce the effect of energy-saving and heat preservation.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0024] See Table 1 for the parts by weight of raw materials in Examples 1 to 4, and the unit is kilogram.

[0025] Table 1

[0026]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

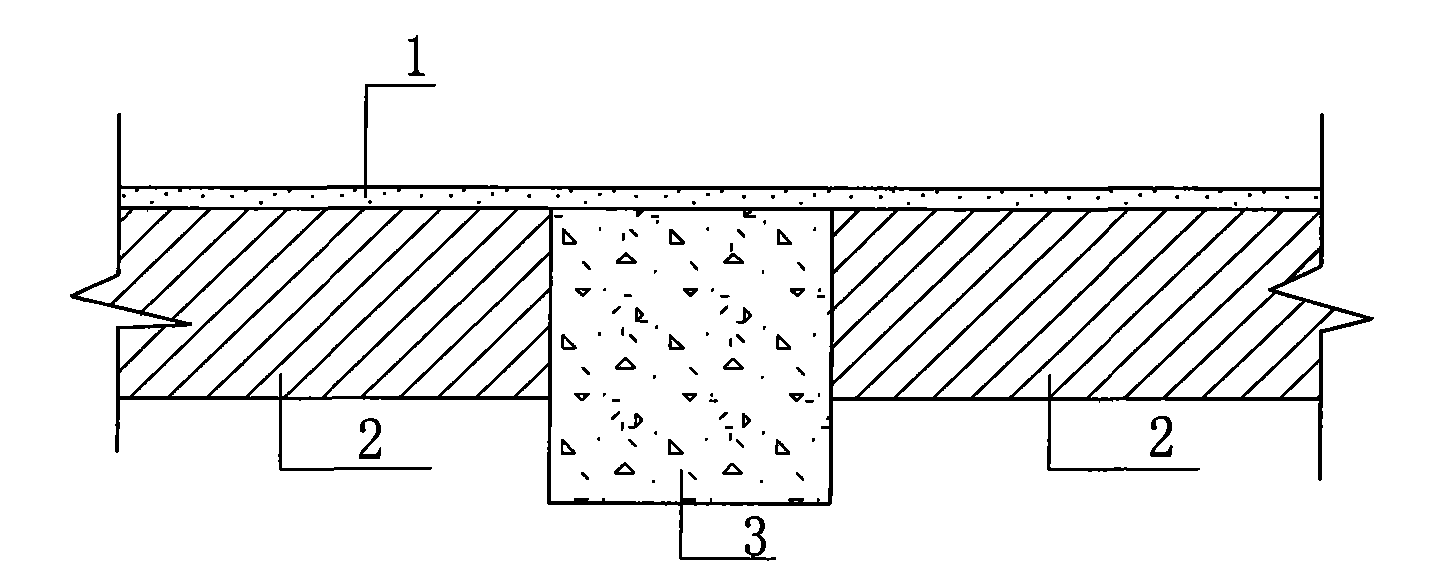

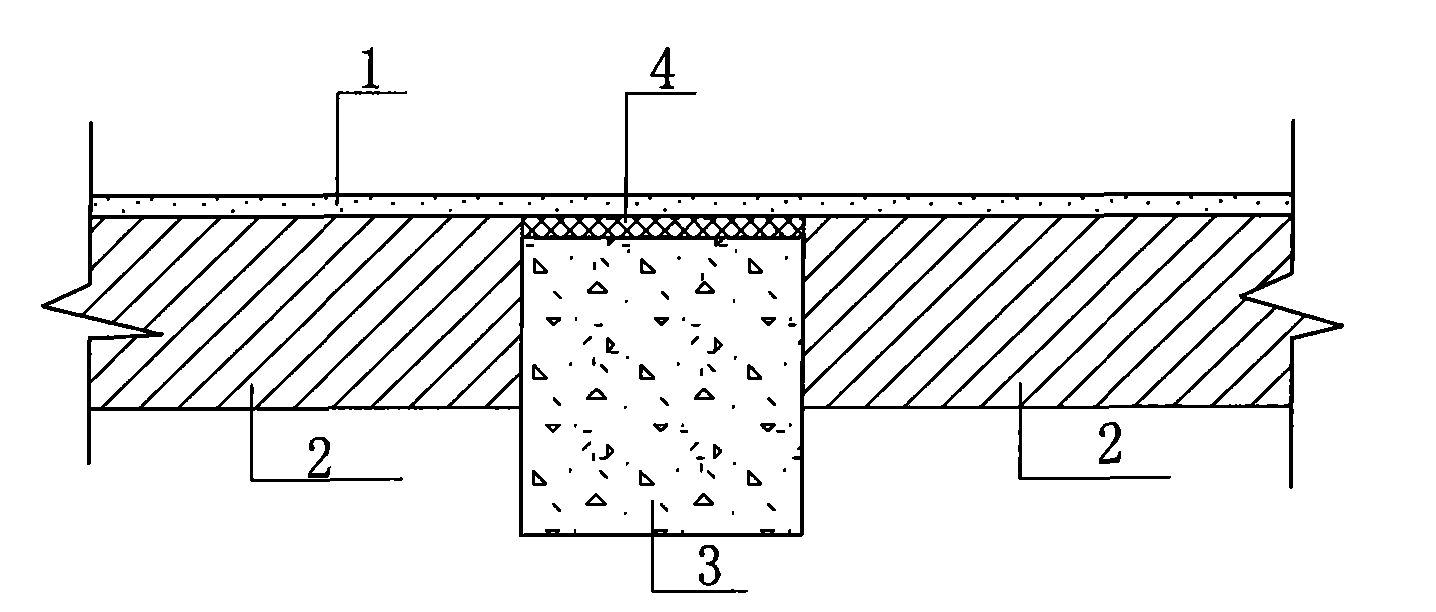

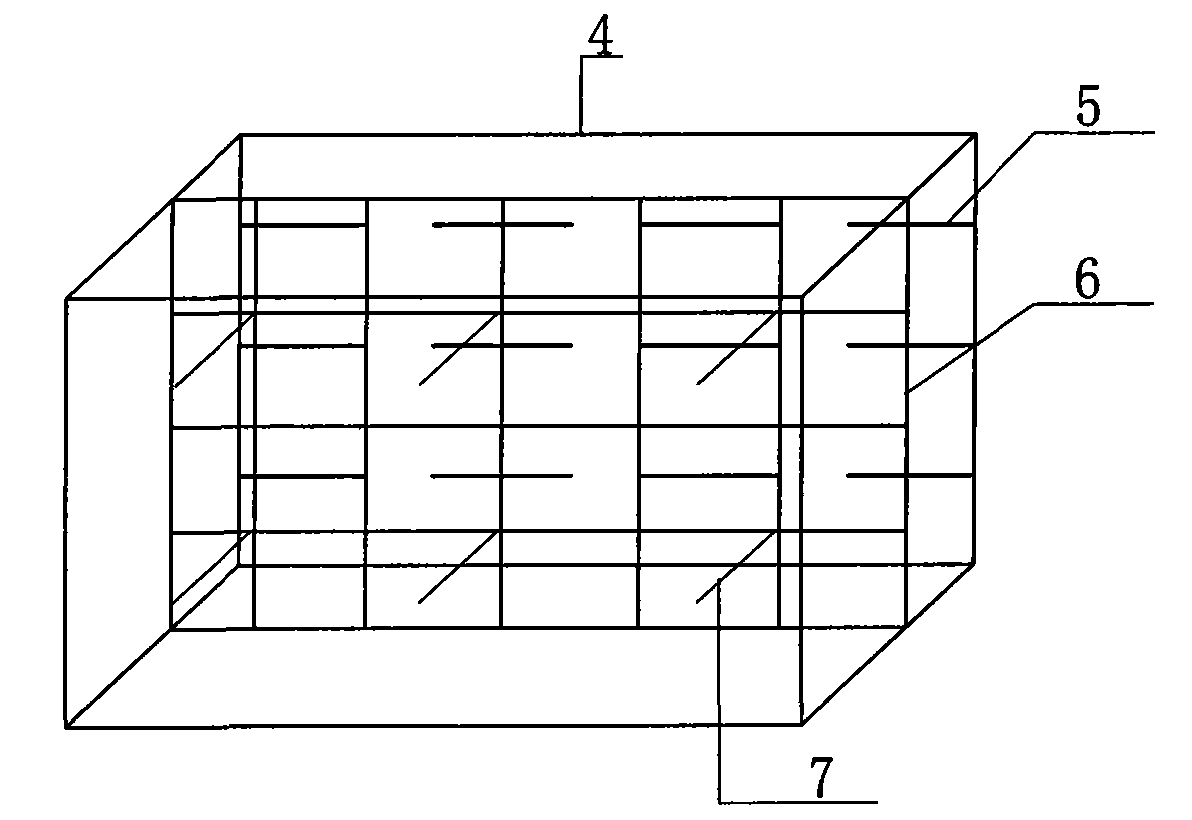

The invention relates to an insulation board of a concrete exterior wall, in particular to the insulation board of the concrete exterior wall at a heat bridge part, which is used in match with the exterior wall body constructed by energy-saving insulation building blocks. The invention is prepared by the following steps: raw materials are mixed, molded by extrusion to obtain the insulation board molding product which is subjected to steam curing and drying to obtain the insulation board molding product of the concrete exterior wall; the invention is characterized in that: before the invention is molded by extrusion, steel mesh is put into the raw materials followed by being molded by extrusion to be the insulation board molding product; the raw materials comprise the following components according to weight percentage: 235-242 parts of silicate cement, 65-67 parts of expanded perlite, 43-45 parts of ceramsite, 80-83 parts of slag, 4-2 parts of plant ash, 1.5-2 parts of wool felt fiber, 0.5-1.0 parts of cloth fiber, 0.5-1.0 parts of bamboo fiber and 94-96 parts of water. The invention has good insulation property, can effectively reduce the heat bridge effect of the exterior wall constructed by energy-saving insulation building blocks, has high breaking strength and can have the same service life with the exterior wall constructed by insulation blocks.

Description

technical field [0001] The invention relates to a thermal insulation board for a concrete outer wall of a building, in particular to a thermal insulation board for a concrete outer wall at a thermal bridge position. Background technique [0002] In the prior art, the development and research of energy-saving exterior walls of houses have been extensively carried out. The method is to smear a certain thickness of thermal insulation mortar or external insulation boards on the exterior wall surfaces of ordinary block walls and concrete columns. Generally, solid clay bricks, hollow bricks, aerated concrete blocks, etc. are used; another way is to directly use energy-saving heat-insulating blocks to build the exterior walls, instead of applying heat-insulating mortar or external insulation boards on the exterior walls. [0003] The above-mentioned methods all have better effects on energy-saving and heat-preservation of the exterior walls, especially the latter method--the exteri...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E04C2/288E04B1/80C04B28/04B28C5/00B28B3/20C04B14/18C04B16/02C04B18/10C04B18/14

CPCC04B28/04C04B2111/00612C04B2111/28Y02W30/91C04B14/185C04B18/023C04B18/101C04B18/141C04B18/248C04B20/0048C04B32/02C04B40/024

Inventor 陶祖歧

Owner 无锡市康顺节能材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com