Honeycomb sandwich panel and making method thereof

A manufacturing method and sandwich panel technology, applied in the direction of chemical instruments and methods, layered products, metal layered products, etc., can solve the problem that the thermal insulation performance cannot meet the requirements of military standard I, and there is no embedded foam honeycomb sandwich panel Manufacturing methods and other issues, to achieve the effect of low cost, good thermal insulation, simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

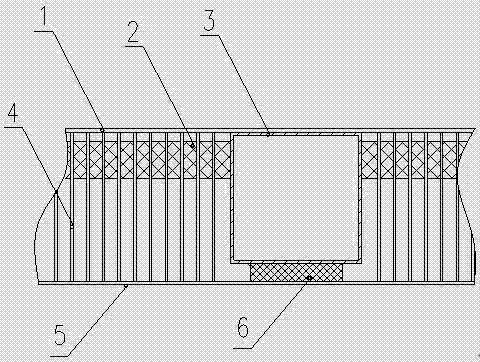

[0028] refer to figure 1 : the honeycomb sandwich panel of the present embodiment, from the outside to the inside, is an outer skin 1, a honeycomb core 4 and an inner skin 5, and the honeycomb core 4 cells are filled with polyurethane rigid foam 2, and the polyurethane rigid foam The thickness is 10mm; there is a skeleton 3 in the middle of the honeycomb sandwich panel, and the surface of the skeleton 3 is laid with a heat insulating material 6, and the heat insulating material is 500kg / m 3 Low-density PVC foam board.

[0029] The outer skin 1 and the inner skin 5 are made of aluminum alloy.

Embodiment 2

[0031] refer to figure 1 : the honeycomb sandwich panel of the present embodiment, from the outside to the inside, is an outer skin 1, a honeycomb core 4 and an inner skin 5, and the honeycomb core 4 cells are filled with polyurethane rigid foam 2, and the polyurethane rigid foam The thickness is 15mm; there is a skeleton 3 in the middle of the honeycomb sandwich panel, and the surface of the skeleton 3 is laid with a heat insulating material 6, and the heat insulating material is 500kg / m 3 Low-density PVC foam board.

[0032] The outer skin 1 and the inner skin 5 are steel plates.

Embodiment 3

[0034] refer to figure 1 : the honeycomb sandwich panel of the present embodiment, from the outside to the inside, is an outer skin 1, a honeycomb core 4 and an inner skin 5, and the honeycomb core 4 cells are filled with polyurethane rigid foam 2, and the polyurethane rigid foam The thickness is 2mm; there is a skeleton 3 in the middle of the honeycomb sandwich panel, and the surface of the skeleton 3 is laid with a heat insulating material 6, and the heat insulating material is 500kg / m 3 Low-density PVC foam board.

[0035] The outer skin 1 is a steel plate; the inner skin 5 is an aluminum alloy material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com