Prefabricated heat preservation wall body

A technology of thermal insulation wall and thermal insulation layer, which is applied in thermal insulation, wall, building components and other directions, can solve the problems of poor corrosion resistance and durability of metal connecting bars, insufficient mechanical performance of connecting parts, and reduced wall thermal insulation effect. , to achieve the effect of good durability, good overall thermal insulation effect and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

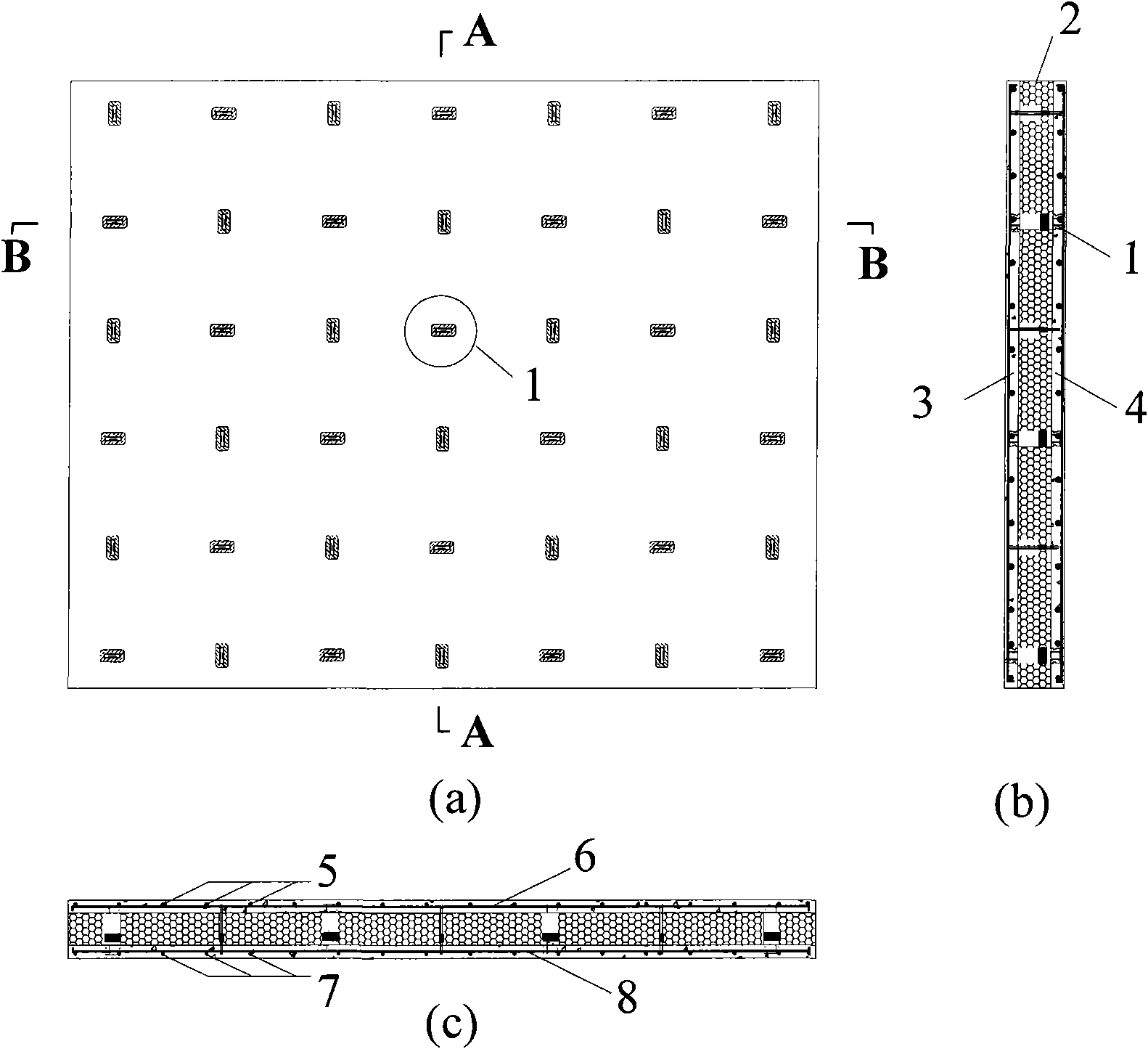

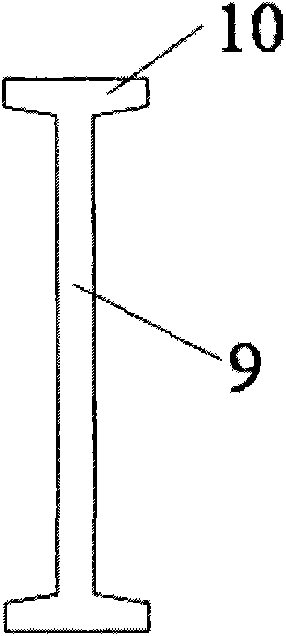

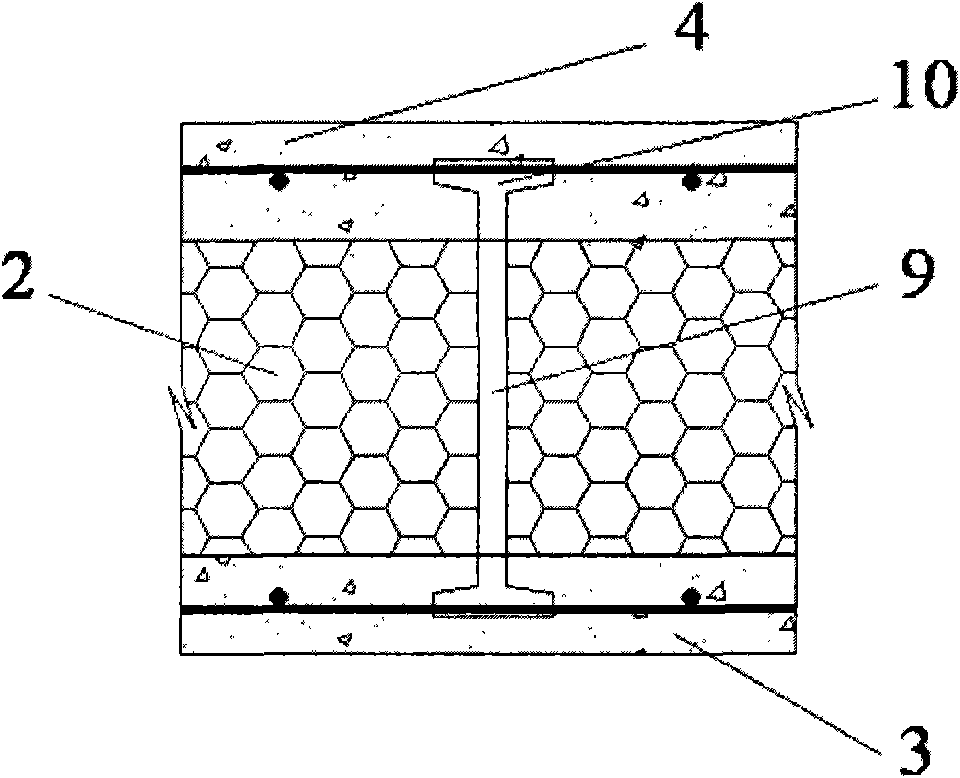

[0026] Example 1: The prefabricated thermal insulation wall is mainly composed of thermal insulation layer 2, concrete inner wall panels 3, concrete outer wall panels 4, longitudinally arranged steel bars 5 in inner wall panels, horizontally arranged steel bars 6 in inner wall panels, and longitudinally arranged inner wall panels. Reinforcing bar 7, horizontally arranged reinforcing bar 8 is formed in the exterior wall panel. The longitudinally arranged steel bars 5 in the inner wall panels and the horizontally arranged steel bars 6 in the inner wall panels are distributed in the concrete inner wall panels 3, and the longitudinally arranged steel bars 7 in the outer wall panels and the horizontally arranged steel bars 8 in the outer wall panels are distributed in the concrete outer wall panels 4 Inside. The FRP connector has an "I"-shaped structure, consisting of a web 9 and a flange 10. There are two flanges 10, located at both ends of the web 9, and the two flanges 10 are re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com