FRP connecting piece of prefabricated heat preservation wall body

A technology for thermal insulation of walls and connectors, applied to walls, building components, buildings, etc., can solve the problems of corrosion safety of connectors, thermal bridges and hidden dangers in connector parts, and achieve good durability and overall thermal insulation effect , The effect of fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

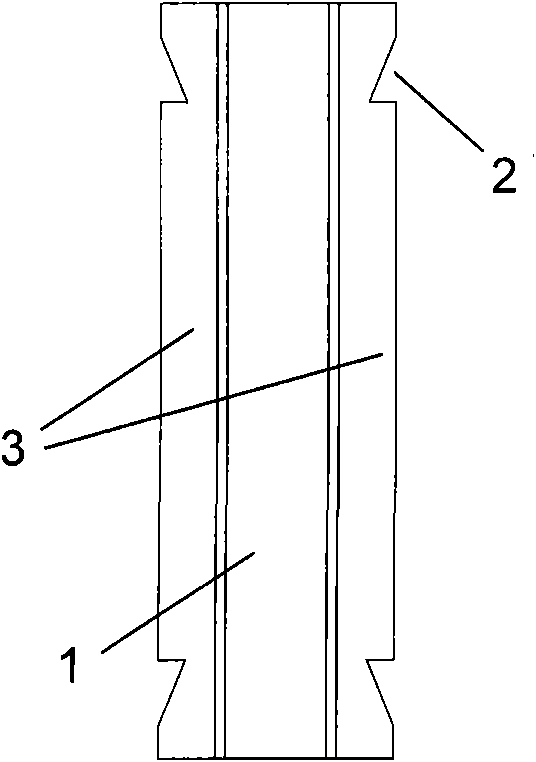

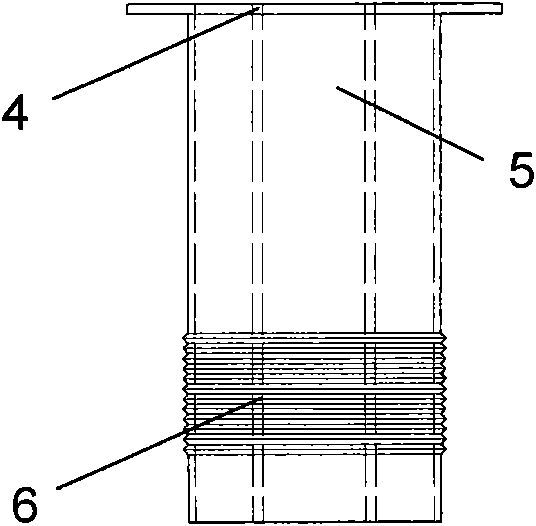

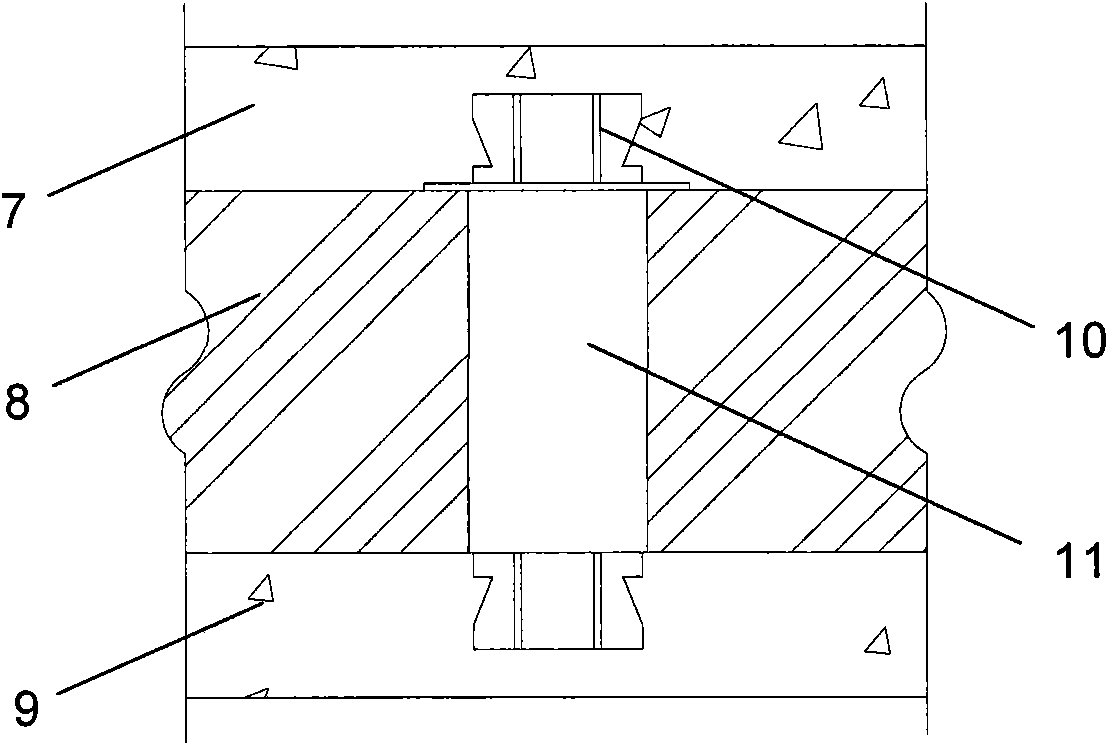

[0020] Embodiment 1, the FRP connecting piece is composed of an FRP connecting plate 10 and a collar 11, the FRP connecting plate 10 is made by a pultrusion process, the collar 11 is made of ABS plastic, and is made into one body through an injection molding process, and the middle part of the FRP connecting plate 10 has a There is a longitudinal groove 1, a rib 3 on the edge, and an anchoring notch 2 at the end of the connecting plate, and its structure is as follows figure 1 shown. Collar 11 is made up of collar cap 4, collar body 5, thread band 6, and its structure is as figure 2 As shown, the collar 11 surrounds and is fixed in the middle of the connecting plate 10 , and the anchoring notches 1 at both ends of the FRP connecting plate 10 are located outside the collar 11 . The collar cap 4 is located at the end of the collar 11 , and the threaded band 6 is located on the collar body 5 . The FRP connecting plate 10 is made by a pultrusion process, and the fiber layer sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com