Three-row hole recycled concrete load-bearing energy-saving composite thermal insulation block and preparation method thereof

A technology of recycled concrete and thermal insulation blocks, which is applied in the manufacture of tools, building materials, ceramic molding machines, etc., and can solve the problems of insufficient utilization of renewable resources, high porosity of single-row hole blocks, and low utilization rate of recycled aggregates. , to achieve the effect of increasing the heat conduction path, good heat preservation effect and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

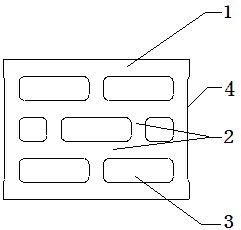

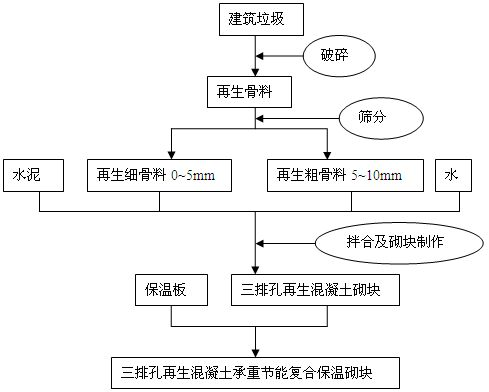

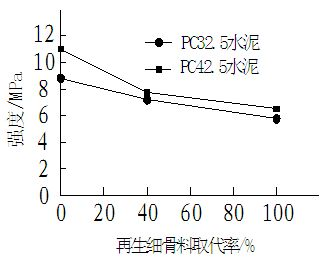

[0018] The three-row hole recycled concrete load-bearing thermal insulation block of the present invention is composed of a wall 1 and a rib 3. The gap between the wall 1 and the rib 2 is a hole 3, and each hole 3 runs through up and down and keeps aligned up and down. There are three holes on the block. Row of holes, each of the holes 3 is filled with insulation boards, and ash slots 4 are arranged on the front and rear sides of the block. Design mortar slot 4 is to make mortar easy to fill in the process of building by laying bricks or stones. The block is made of raw materials in the following weight ratio: cement: water: recycled fine aggregate: recycled coarse aggregate =375:150:664:811.

[0019] According to the influence of block pass design on block load-bearing and the influence principle of block heat conduction path on heat preservation effect, the applicant has determined the pass and specification of the three-row hole recycled concrete block of the present invent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com