Double-layer polyester film and preparation method thereof

A polyester and film technology, applied in the direction of polyurea/polyurethane coatings, coatings, film/flake adhesives, etc., to achieve the effect of strong self-cleaning ability, excellent thermal insulation performance and good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

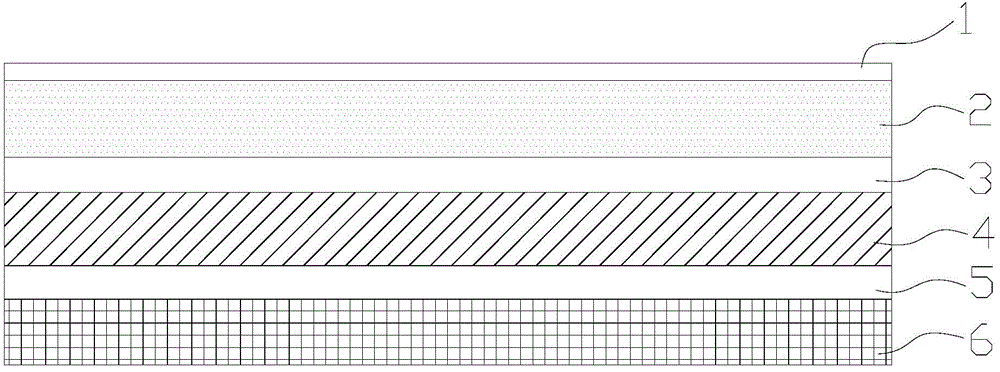

Image

Examples

Embodiment 1

[0028] This embodiment provides a double-layer polyester film and the preparation method of the double-layer polyester film, specifically as follows:

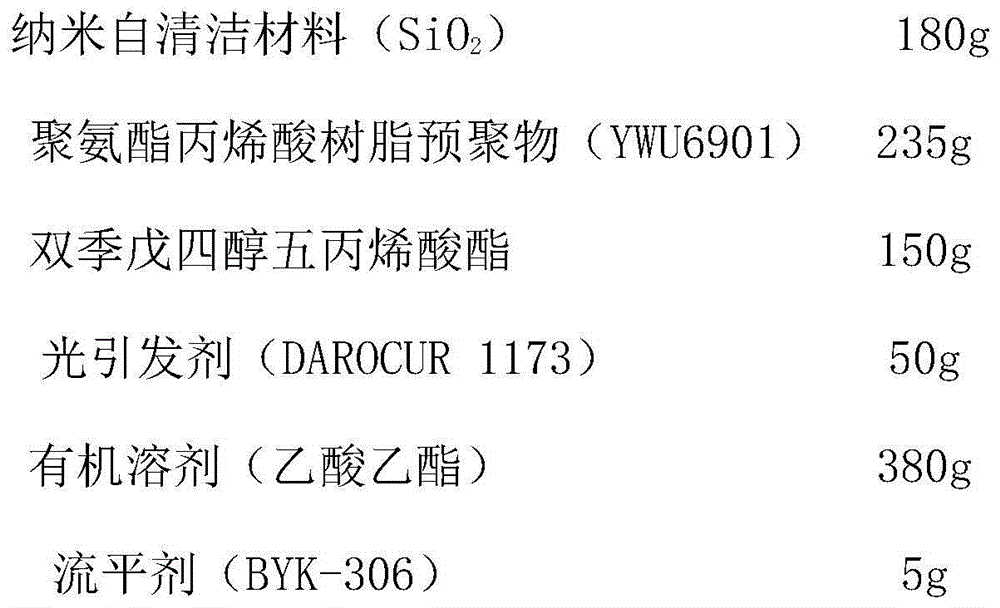

[0029] Self-cleaning coatings consist of the following components:

[0030]

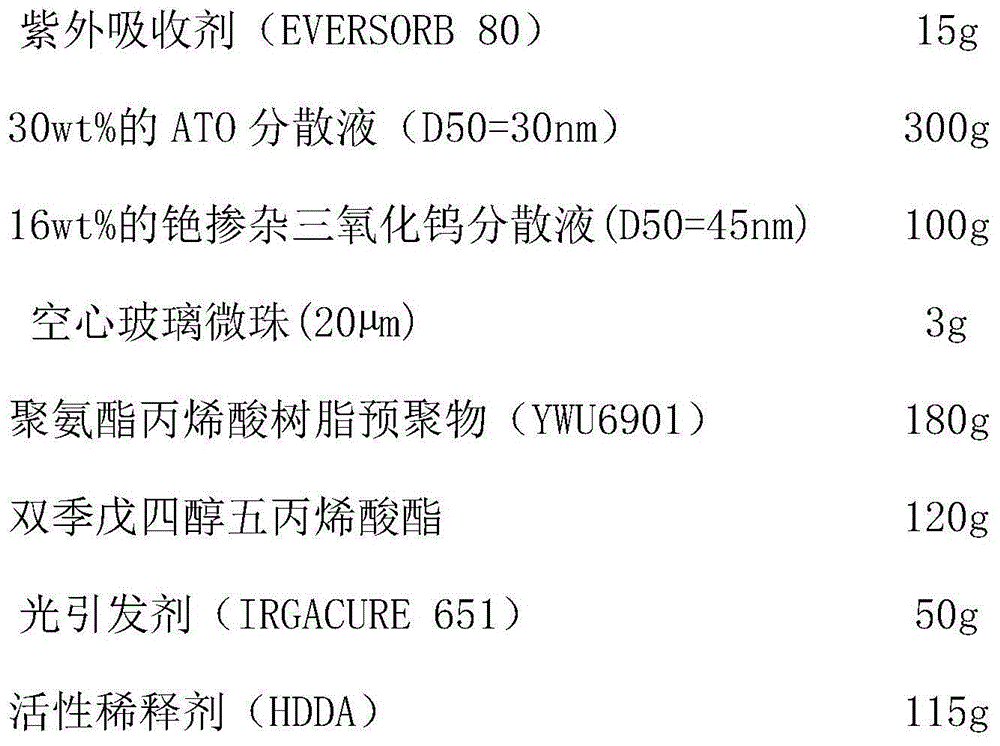

[0031] Anti-ultraviolet and infrared coatings are composed of the following components in mass percentage:

[0032]

[0033]

[0034] The preparation method is as follows:

[0035](1) According to the above components and weights of the self-cleaning coating, each component was weighed and mixed together, and then the mixture was stirred at a speed of 300r / min for 30min to mix the components uniformly to obtain a self-cleaning coating.

[0036] An optical-grade PET substrate with a thickness of 25 μm and double-sided deep corona treatment was used as the first substrate layer, and a 5 μm thick self- Clean paint. Heat-treat the first substrate layer at 70°C for 3 minutes, then place the first substrate layer in a UV curing box for photocuri...

Embodiment 2

[0041] This embodiment provides a double-layer polyester film and the preparation method of the double-layer polyester film, specifically as follows:

[0042] Self-cleaning coatings consist of the following components:

[0043]

[0044] Anti-ultraviolet and infrared coatings are composed of the following components in mass percentage:

[0045]

[0046]

[0047] The preparation method is as follows:

[0048] (1) According to the above composition and weight of each component of the self-cleaning coating, weigh each component respectively. Dissolve IRGACURE 651 in propylene glycol methyl ether acetate, and stir at 300r / min at 60°C for 30min to mix the two evenly. The mixture was cooled to room temperature, and then the remaining components were added to the mixture, and the stirring was continued at a speed of 300 r / min for 30 min to obtain a self-cleaning coating.

[0049] An optical-grade PET substrate with a thickness of 38 μm and double-sided deep corona treatmen...

Embodiment 3

[0054] This embodiment provides a double-layer polyester film and the preparation method of the double-layer polyester film, specifically as follows:

[0055] Self-cleaning coatings consist of the following components:

[0056]

[0057] Anti-ultraviolet and infrared coatings are composed of the following components in mass percentage:

[0058]

[0059]

[0060] The preparation method is as follows:

[0061] (1) According to the above composition and weight of each component of the self-cleaning coating, weigh each component respectively. Dissolve LUCIRIN TPO in methyl isobutyl (methyl) ketone, and stir at 300r / min at 60°C for 30min to mix the two evenly. The mixture was cooled to room temperature, and then the remaining components were added to the mixture, and stirring was continued at a speed of 300r / min for 30min, obtained from a clean paint.

[0062] Take a 25 μm optical-grade hot-melt adhesive TPU substrate as the first substrate layer, and apply a 6 μm thick ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com