Composite armored thermal insulation wall of foamed concrete and construction method thereof

A foam concrete and thermal insulation wall technology, applied in the direction of thermal insulation, walls, building components, etc., can solve the problems of low service life, small stress points of concrete slabs, low compressive strength of external walls, etc., and achieve compression resistance Strong ability, convenient construction and superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

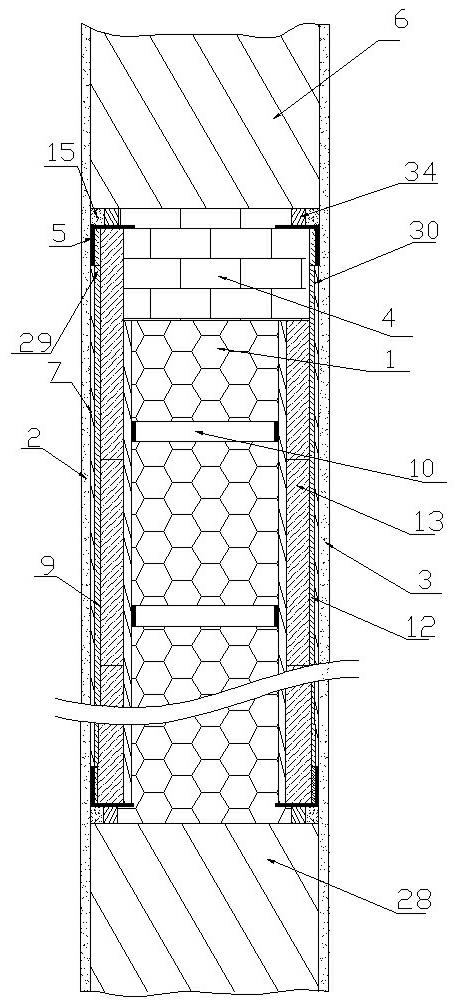

[0088] A construction method for a foam concrete composite armored thermal insulation wall, in which a window and a water and electricity control cabinet are arranged on the wall, and when the load-bearing column 11 and the upper and lower ring beams are provided with a reserved steel bar head 34, the method steps are as follows:

[0089] Step 1, the load-bearing column 11, the upper ring beam 6 and the lower ring beam 28 of the building are respectively set, and the distance between the outer surface of the upper ring beam 6 and the lower ring beam 28 and the outer surface of the load-bearing column 11 is 50mm;

[0090] Step 2. On the opposite sides of the two load-bearing columns 11, weld a vertical angle steel along the inner edge, respectively weld a horizontal angle steel on the lower end surface of the upper ring beam 6 and the upper end surface of the lower ring beam 28, and place the load-bearing column 11 The angle steel on the top and the angle steel on the upper and ...

Embodiment 2

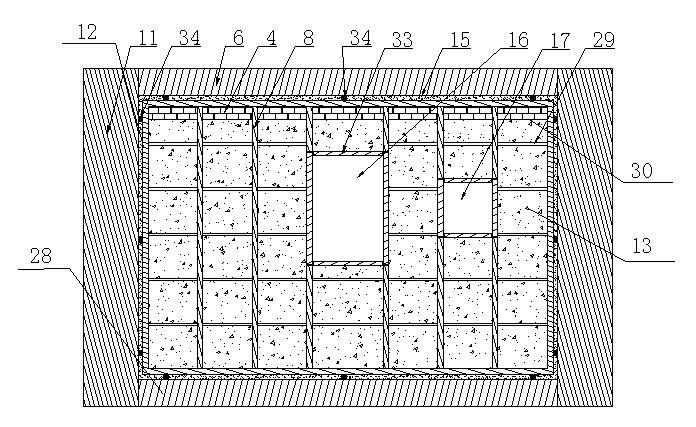

[0106] A construction method of a foam concrete composite armored thermal insulation wall, when a door is provided on the wall, and a reserved steel bar head 34 is provided on the load-bearing column 11 and the upper and lower ring beams, the method steps are:

[0107] Step 1, the load-bearing column 11, the upper ring beam 6 and the lower ring beam 28 of the building are respectively set, and the distance between the outer surface of the upper ring beam 6 and the lower ring beam 28 and the outer surface of the load-bearing column 11 is 80mm;

[0108] Step 2. On the opposite sides of the two load-bearing columns 11, weld a vertical angle steel along the inner edge, respectively weld a horizontal angle steel on the lower end surface of the upper ring beam 6 and the upper end surface of the lower ring beam 28, and place the load-bearing column 11 The angle steel on the top and the angle steel on the upper and lower ring beams are welded to form a fixed frame 14; in the fixed fram...

Embodiment 3

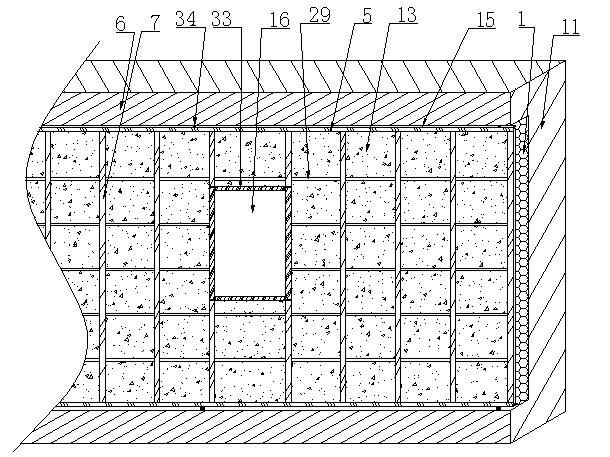

[0125] A construction method for a foam concrete composite armored thermal insulation wall. When there are no windows, doorways, and water and electricity control cabinets on the wall, and there are no reserved steel bar heads 34 on the load-bearing columns 11 and the upper and lower ring beams, then it is necessary to install them on the load-bearing columns. 11 and the upper and lower ring beams are used to fix the load-bearing column angle steel 26, the angle steel 5 on the outer wall layer 9 and the fixed frame 14. Install expansion bolts to replace the reserved steel head 34. When installing the expansion bolts, drill holes first 1. Grouting cement mortar, then inserting expansion bolts, fastening, and then installing the inner wall panel layer 12 and the outer wall panel layer 9, the method steps are:

[0126] Step 1, the load-bearing column 11, the upper ring beam 6 and the lower ring beam 28 of the building are respectively set, and the distance between the outer surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com