Liquid hydrogen storage material and preparation method thereof

A technology for liquid hydrogen storage and hydrogen storage materials, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the problems of slow heating of hydrogen storage materials and difficulty in dehydrogenation, and achieve the effect of increasing the release rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

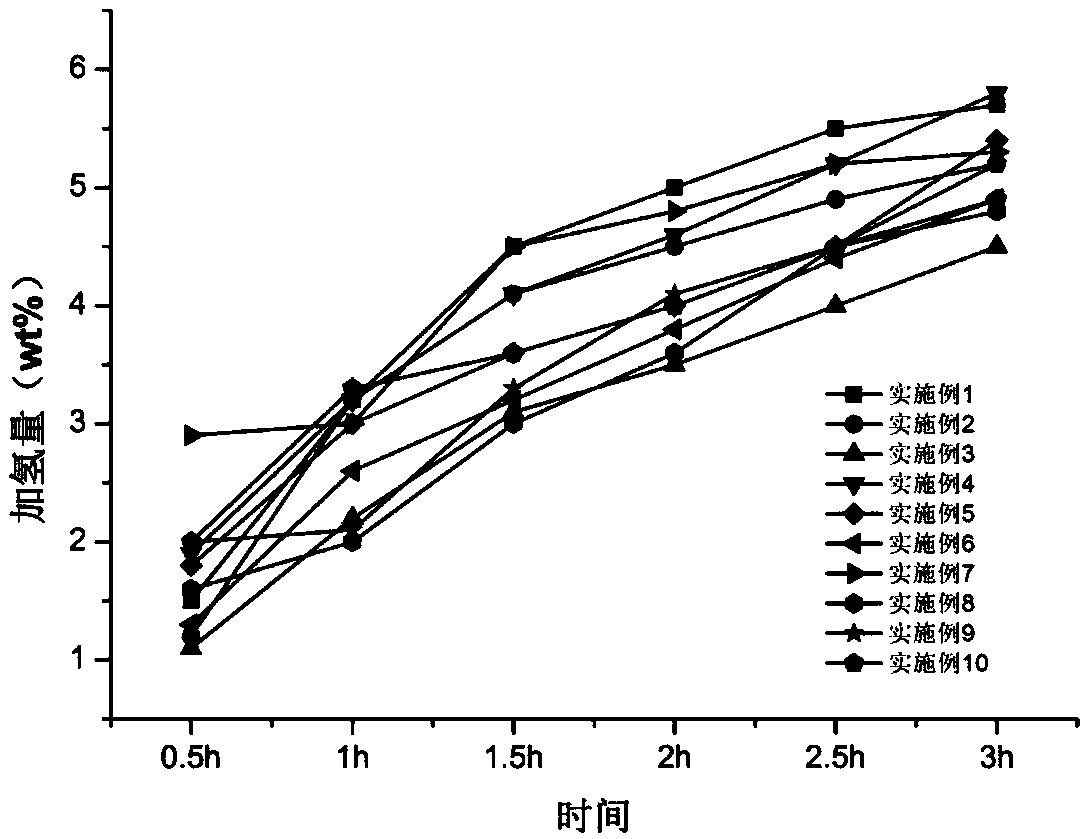

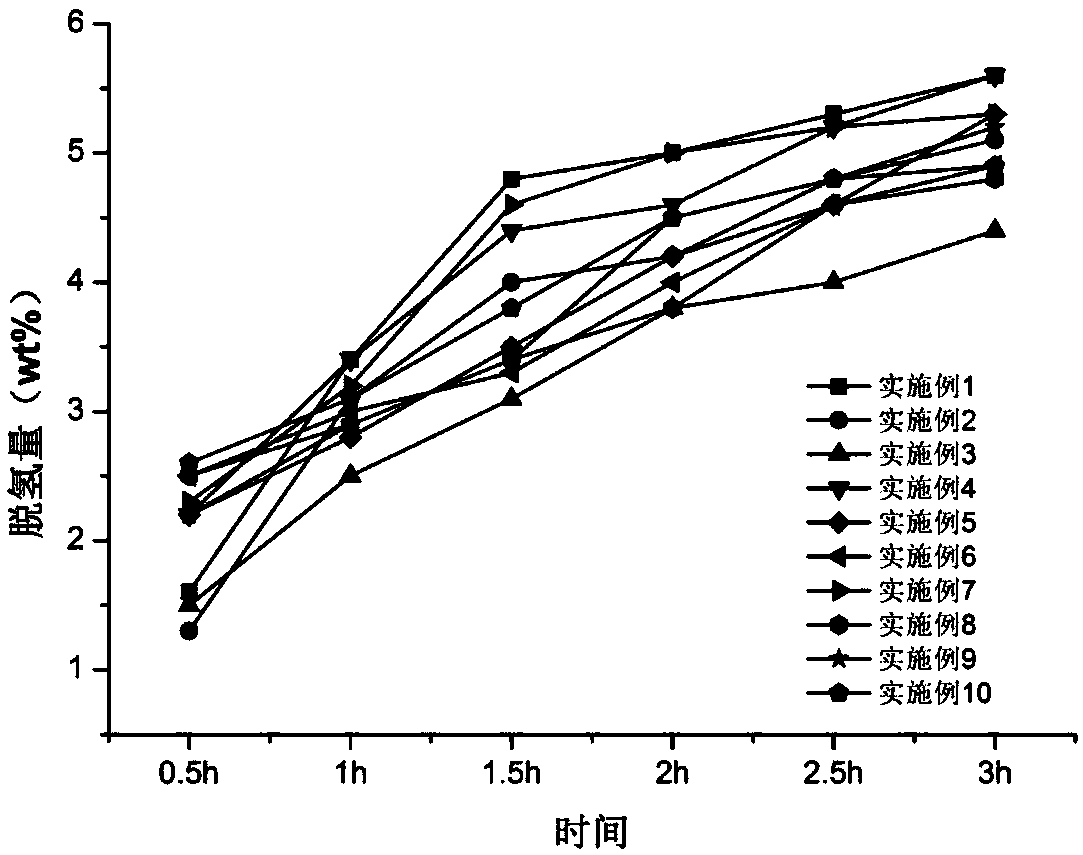

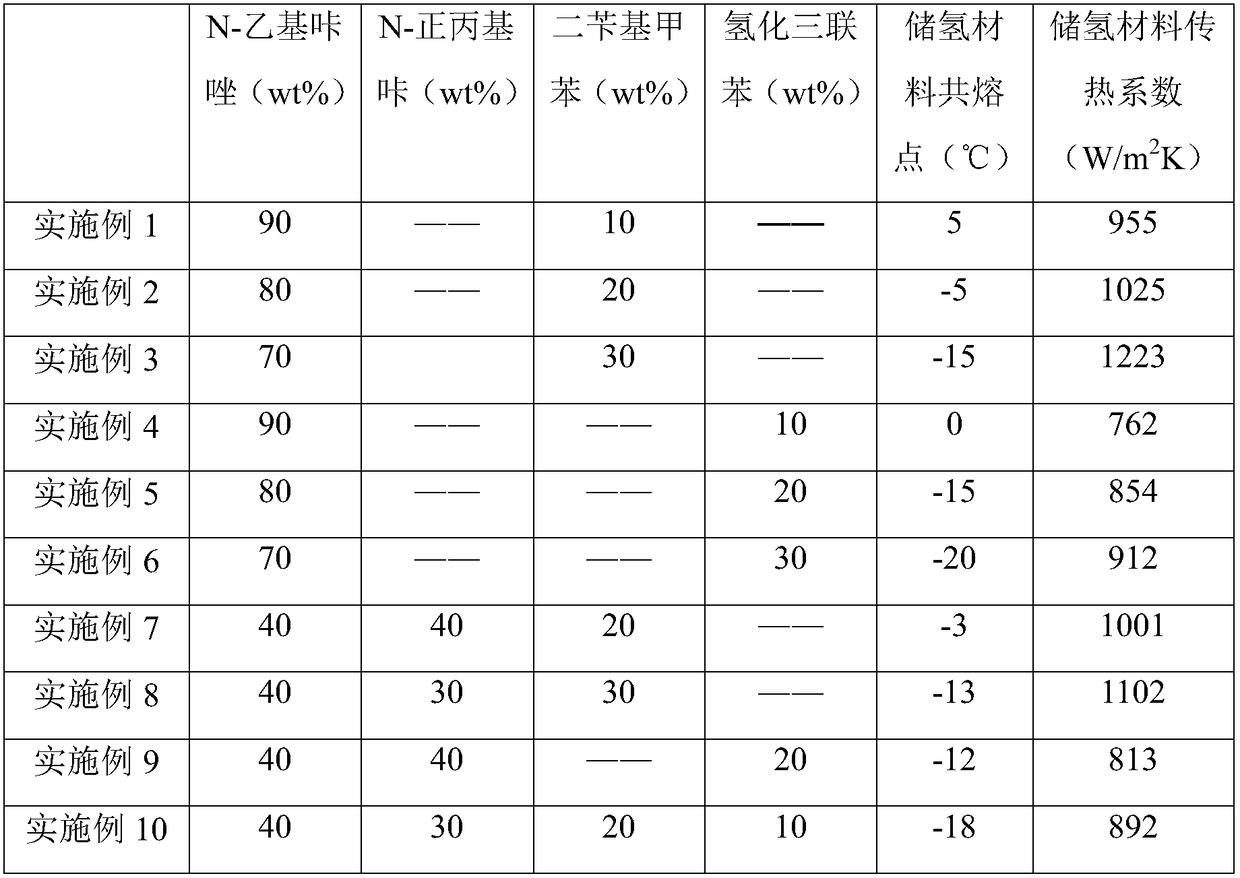

Examples

Embodiment 1

[0022] A liquid hydrogen storage material and a preparation method thereof, comprising the steps of:

[0023] A. Put 90g of N-ethylcarbazole into a three-neck flask and heat it to 80°C. After the N-ethylcarbazole is completely melted, put a magnet into it and stir vigorously.

[0024] B. Slowly add 10 g of dibenzyltoluene to the molten N-ethylcarbazole in step 1. After the addition is completed, continue stirring for 3 h until a uniform mixture is formed.

[0025] C. Stop heating, cool the mixture in step 2 to room temperature, and then put the mixed material into a grinding bottle to obtain the hydrogen storage material.

Embodiment 2

[0027] A liquid hydrogen storage material and a preparation method thereof, comprising the steps of:

[0028] A. Put 80g of N-ethylcarbazole into a three-neck flask and heat it to 90°C. After the N-ethylcarbazole is completely melted, put a magnet into it and stir vigorously.

[0029] B. Slowly add 20 g of dibenzyltoluene to the molten N-ethylcarbazole in step 1. After the addition is completed, continue stirring for 3 h until a uniform mixture is formed.

[0030] C. Stop heating, cool the mixture in step 2 to room temperature, and then put the mixed material into a grinding bottle to obtain the hydrogen storage material.

Embodiment 3

[0032] A liquid hydrogen storage material and a preparation method thereof, comprising the steps of:

[0033] A. Put 70g of N-ethylcarbazole into a three-necked bottle and heat it to 90°C. After the N-ethylcarbazole is completely melted, put a magnet into it and stir vigorously.

[0034] B. Slowly add 30 g of dibenzyltoluene to the molten N-ethylcarbazole in step 1. After the addition is completed, continue stirring for 4 h until a uniform mixture is formed.

[0035] C. Stop heating, cool the mixture in step 2 to room temperature, and then put the mixed material into a grinding bottle to obtain the hydrogen storage material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com