Multifunctional composite thermal-insulating layer

A multi-functional, heat-insulating layer technology, applied in the direction of heat preservation, pipeline protection, and protection of pipelines through heat insulation, etc., can solve the problems of large heat loss, rising temperature of the outer surface of the insulating layer, and hidden safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Shougang steelmaking RH furnace superheated steam pipe insulation renovation project, pipe diameter DN325, length 906m, medium temperature 285 ℃, the experimental implementation steps are as follows:

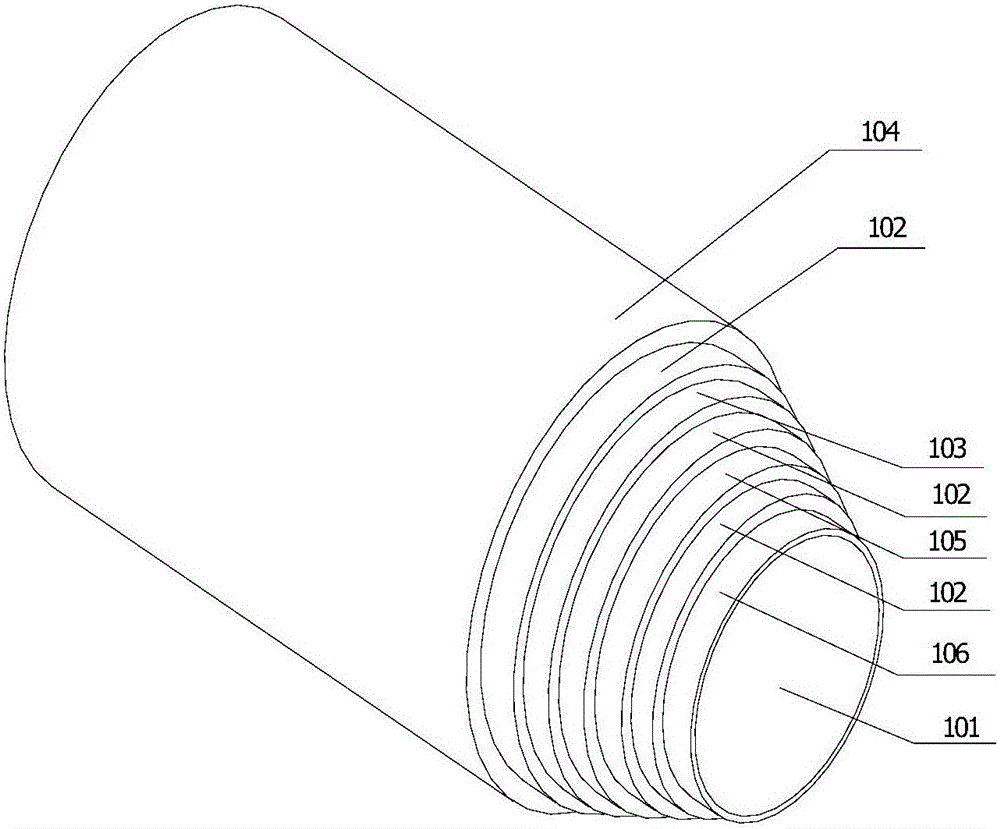

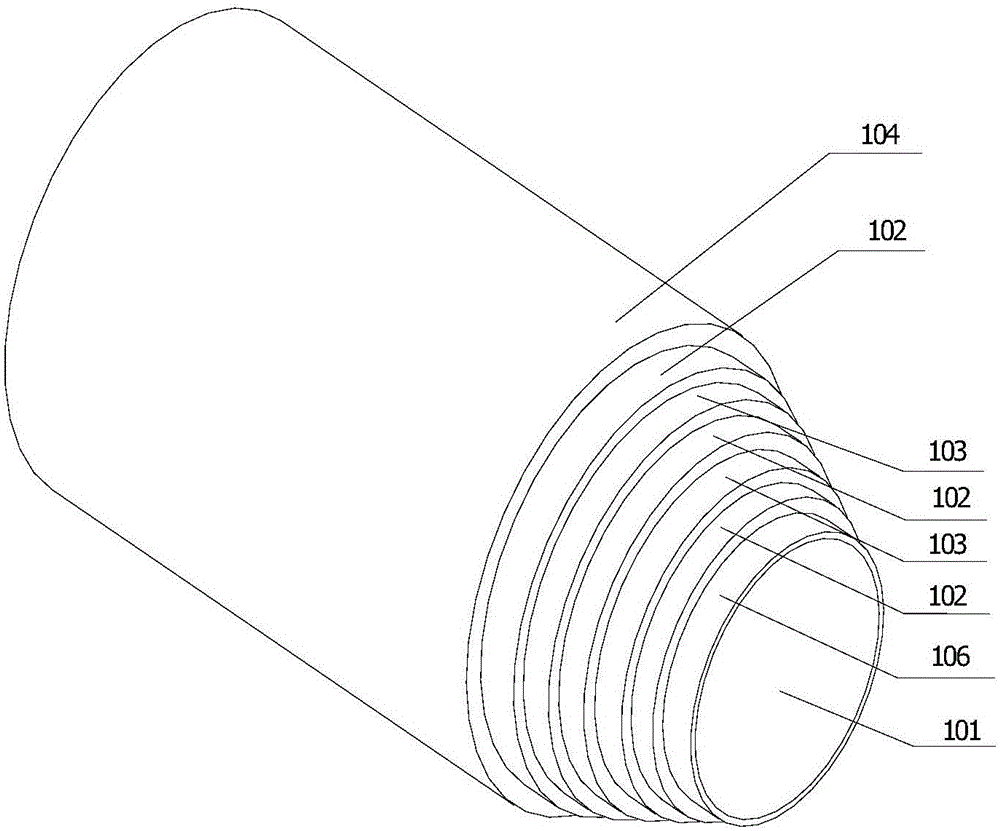

[0050] 1. Install a layer of isolation layer 106 of high-temperature-resistant emission material close to the pipeline or equipment substrate 101, and then install a layer of inner protective layer 102 containing pick fiber material. The thickness of the inner protective layer is controlled at 12mm, and the thickness of the isolation layer is controlled at 1mm;

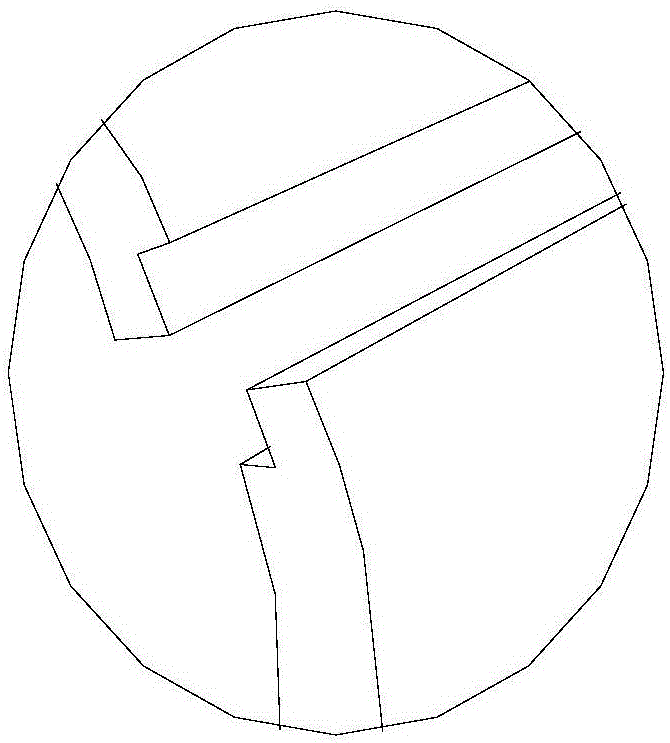

[0051] 2. Install the full normal emissivity according to the temperature between the inner protective layer and the insulation layer. Select the emission layer 105 of the heat barrier emission glass with a thickness of 50mm. Cut into multiple insulation tiles according to the surface shape of the thermal equipment and the pipeline, and overlap each other. direct connection;

[0052]3. Install an inner protectiv...

Embodiment 2

[0057] 30WM unit main steam pipe insulation renovation project, pipe diameter DN325, length 170m, medium temperature 545°C, the experimental implementation steps are as follows:

[0058] 1. Install the isolation layer 106 of high-temperature-resistant emission material close to the pipeline or equipment substrate 101, and then install the inner protective layer 102 of crystal fiber. The thickness of the inner protective layer is controlled at 12mm to serve as a protective layer between the pipeline substrate and the insulation layer. Thermal expansion and decompression and shock absorption, supporting the overall insulation structure from collapsing, to protect the pipeline matrix and insulation layer, the thickness of the isolation layer is controlled at 100mm and divided into three layers of painting;

[0059] 2. According to the outer surface temperature of the first inner protection layer 102, install a layer of calcium silicate insulation layer 103, the thickness of the in...

Embodiment 3

[0066] Beijing Thermal Power Group Co., Ltd. Yuetan Unicom line main line reconstruction project, pipe diameter DN720, length 3920m, medium temperature 103 ℃, the experimental implementation steps are as follows:

[0067] 1. Install the insulating layer 106 of high-temperature-resistant emissive material close to the pipeline or equipment substrate 101, and then install the inner protective layer 102 of airgel. The thickness of the inner protective layer is controlled at 2 mm as a protective layer between the pipeline substrate and the insulation layer Absorb thermal expansion and decompression and shock absorption, support the overall insulation structure from collapsing, so as to protect the pipeline substrate and insulation layer, the thickness of the isolation layer is controlled at 80mm and divided into two layers, which are attached to the surface of the pipeline or equipment substrate by surface melting;

[0068] 2. According to the temperature of the outer surface of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com