Heat generation tool

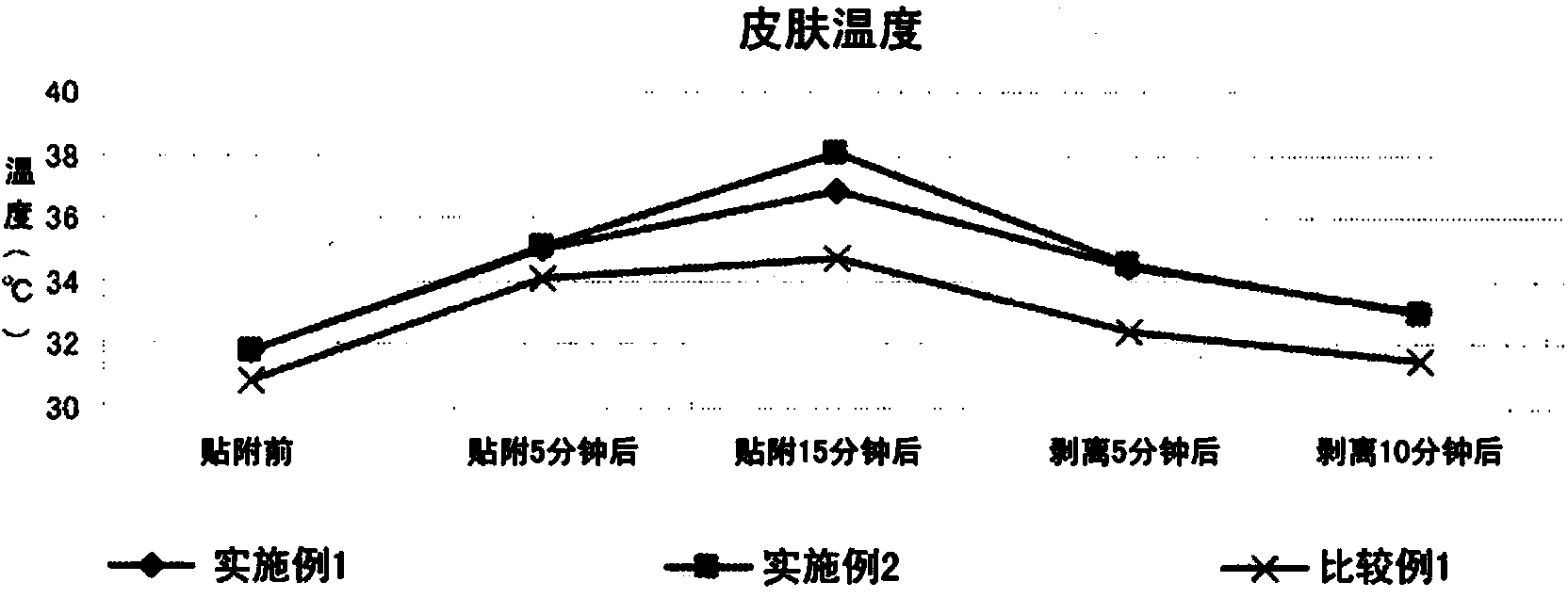

A device and heat generation technology, which can be applied in the directions of heating devices for therapeutic treatment, cooling devices for therapeutic treatment, contraceptive devices, etc. problem, achieve excellent warming effect, eliminate tightness, and warm the skin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

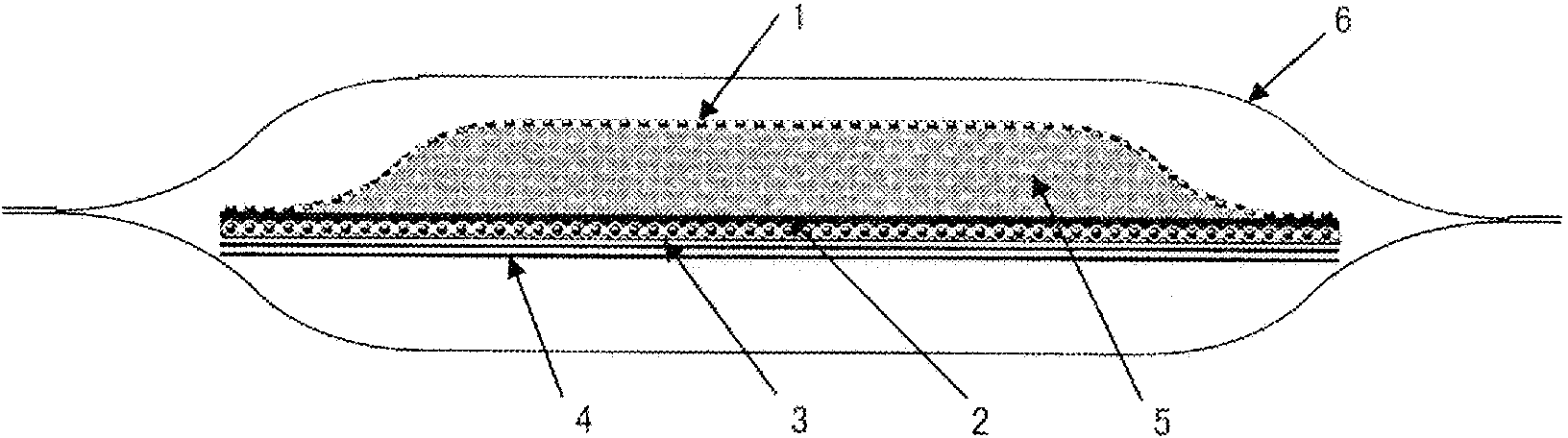

Embodiment 1

[0109] Liquid paraffin (manufactured by Matsumura Petroleum Research Institute, boiling point at 1 atm: 100°C or higher, specific heat at 20°C: 1.88 J / g·K) as an oil component and polystyrene-polyethylene as a base - A polybutylene-polystyrene copolymer (SEBS) (manufactured by Kraton Polymers) was dissolved to prepare an adhesive layer 1 containing 80% by weight of liquid paraffin and 20% by weight of SEBS. The specific heat of the adhesive layer 1 was 1.96 J / g·K at 20°C.

[0110]On the other hand, iron powder (manufactured by DOWA IP CREATION CO., LTD., trade name DKP, average particle diameter of 100 μm), water, activated carbon (FUTAMURA CHEMICAL CO., LTD., trade name Taihe activated carbon, average particle diameter of 50 μm), vermiculite (average particle diameter is about 500 μm), water-absorbent resin (acrylic acid polymer partial salt cross-linked product, average particle diameter is 250 μm), and salt are mixed to prepare iron powder containing 55% by weight, water 25...

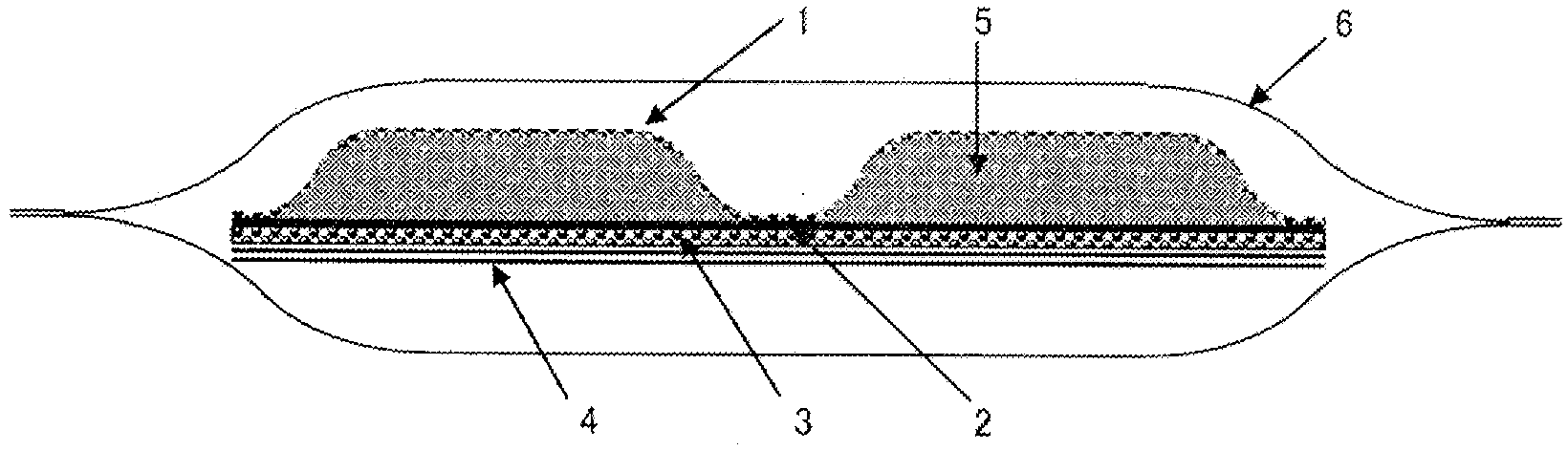

Embodiment 2

[0113] As the oil component, instead of liquid paraffin, silicone oil (manufactured by Shin-Etsu Chemical Co., Ltd., boiling point at 1 atm: 100° C. or higher, specific heat at 20° C.: 1.67 J / g·K) was used instead of liquid paraffin. In the same manner as above, an adhesive layer 2 containing 80% by weight of silicone oil and 20% by weight of SEBS was prepared. In addition, using the aforementioned heat generating device 1, a heat generating device including an adhesive layer 2 was obtained in the same manner. It should be noted that, here, the thickness of the adhesive layer 2 is about 200 μm.

Embodiment 3

[0115] Except that the content of liquid paraffin in the adhesive layer was set to 60% by weight, and SEBS was set to 40% by weight, the same operation as in Example 1 was carried out to prepare liquid paraffin containing 60% by weight and 40% by weight. Adhesive layer 3 of SEBS. The specific heat of the adhesive layer 3 was 1.86 J / g·K at 20°C. Moreover, it carried out similarly to Example 1, and obtained the heat generating device provided with the adhesive layer 3. It should be noted that, here, the thickness of the adhesive layer 3 is about 200 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com